|

By accessing or using The Crittenden Automotive Library™/CarsAndRacingStuff.com, you signify your agreement with the Terms of Use on our Legal Information page. Our Privacy Policy is also available there. |

DKW Oil Injection

|

|---|

|

|

DKW Oil Injection

Budd Blume, TMS Tech Ed.

Today's Motor Sports

January 1962

A traditional curse of 2-cycle motoring fades away for 1962. Inasmuch as

one of the two 2-stroke imported machines is concerned, at least. Fouled plugs, plentiful at low idle RPM's, and excessive smoke at

most speeds will be greatly diminished in Auto Union-DKW cars for '62 because of a major breakthrough-type development: Oil Injection.

Operating very much on the same principle as fuel injection—only as far as

demand is concerned, the DKW-originated oil injection system beats the old hoodoo of mixing gas and oil at the tank. Now, oil is held in a small, firewall-mounted reservoir, from which it is drawn in quantities directly proportionate with the 2-stroke engine's needs. It's not a new idea, by any means, but the mechanical expression of the long-time desire by 2-cycle designers is meritorious, we think.

The ratio of gas to oil, using the new system, is now reduced from 40:1 to 100:1 for normal driving, and can go as low as 200:1, depending on engine RPM and loading.

Previously, a one-shot mix was made at filling station stops, and proportion of oil to gas was fixed. At low RPM, or idle, plugs could foul with ridiculous ease. The driver became an expert at diagnosing which of the 3 plugs was the greasy culprit. And when cross-country, high-speed running was the order of the day, there was always a trace of doubt about how those roller bearings were faring.

With DKW, (new edition, please note) the amount of fresh oil injected will be small when the engine is running out of gear or idling. At full throttle, the injection system will automatically meter the required amount of oil to handle higher stresses. You can see that engine life (not to mention plug life) will be increased.

An oil supply indicator light is added to the dashboard instrument grouping. New light-alloy pistons are featured with DKW's 800 cc power plant. Main bearings are permanently-sealed in a special

lifetime lubricant.

It's fairly plain to see that Auto Union's merger with Daimler-Benz A.G. is beginning to pay off. Now . . . for styling?

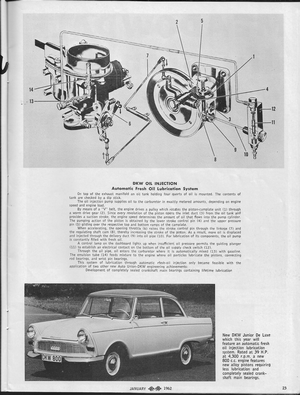

DKW OIL INJECTION

Automatic Fresh Oil Lubrication System

On the top of the exhaust manifold an oil tank holding four quarts of oil is mounted. The contents of tank are checked by a dip stick.

The oil injection pump supplies oil to the carburetor in exactly metered amounts, depending on engine speed and engine load.

By means of a "V" belt, the engine drives a pulley which rotates the piston-camplate unit (1) through a worm drive gear (2). Since every revolution of the piston opens the inlet duct (3) from the oil tank and provides a suction stroke, the engine speed determines the amount of oil that flows into the pump cylinder. The pumping action of the piston is obtained by the lower stroke control pin (4) and the upper pressure pin (5) gliding over the respective top and bottom ramps of the camplate.

When accelerating, the opening throttle (6) raises the stroke control pin through the linkage (7) and the regulating shaft cam (8), thereby increasing the stroke of the piston. As a result, more oil is displaced and injected through the delivery duct (9) into oil pipe (10). For lubrication of its components, the oil pump is constantly filled with fresh oil.

A control lamp on the dashboard lights up when insufficient oil pressure permits the guiding plunger (11) to establish an electrical contact on the bottom of the oil supply check switch (12).

Through the oil pipe, oil enters the carburetor where it is automatically mixed (13) with gasoline. The emulsion tube (14) feeds mixture into the engine where oil particles lubricate the pistons, connecting rod bearings, and wrist pin bearings.

This system of lubrication through automatic rfesh-oil injection only became feasible with the application of two other new Auto Union-DKW engineering achievements:

Development of completely sealed crankshaft main bearings containing lifetime lubrication