|

By accessing or using The Crittenden Automotive Library™/CarsAndRacingStuff.com, you signify your agreement with the Terms of Use on our Legal Information page. Our Privacy Policy is also available there. |

Sintz's Important Contribution to the Birth of the Automobile

|

|---|

|

|

Sintz's Important Contribution to the Birth of the Automobile

George DeAngelis and Murray Fahnestock

Antique Automobile

March-April 1972

Before the turn of the century, operating a gasoline engine was accompanied by a great deal of uncertainty. It was not just a question of would it start at all, but if it started, would it run long enough to get the mixture adjusted to the proper proportion to keep it running for any length of time. At its beginning, the internal combustion engine was complicated, bulky, very heavy and at best useful only as a stationary source of power. It was not very long, however, before early engine designers had produced a package of portable proportions. American makers of small cast iron engines, mostly of the 2-cycle type, literally proliferated and by 1890 over 20,000 engines were in use in boats, lumber camps and farm wells.

The influence of the early European automobile on American automobile pioneers has often been exaggerated. With 20,000 small gasoline engines in practical use in the United States as early as 1890, three years before the first European car was shown here, it was only necessary to put one of these on wheels to build the first American gasoline powered car.

The Sintz 2-cycle engines played an important part in early engine development, not only for stationary and marine use, but also for early automobiles.

Like Shakespeare's favorite, Sir John Falstaff, who wittily remarked, "I am not only witty myself but also the source of wit in other men," the Sintz engine was not only of advanced engineering design but was also the source of engineering advances in other engines.

One of the exhibitors at the Chicago Columbian Exposition in 1893 was the Sintz Gas Engine Company of Grand Rapids, Michigan. The Sintz engine attracted the attention of would-be auto builder Charles B. King. He ordered an engine of 3-inch bore and 3-inch stroke to use in a horseless carriage. He experimented with the engine and soon started making plans for one of his own. Later in 1896, King was the first to drive a gasoline powered wagon in the streets of Detroit.

Elwood Haynes of Kokomo, Indiana, obtained a one horsepower Sintz engine from the factory in Grand Rapids and employed the Apperson brothers to build a car around it. The car was first driven on July 4, 1894. A year later, Haynes replaced the first engine with a larger 2-horsepower Sintz, thus securing 100% increase in horsepower in a single year. This car still exists and can be seen at the Smithsonian Institution in Washington, D.C.

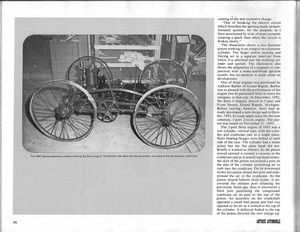

Schloemer, of Milwaukee, built a motor wagon powered with a Sintz engine, which he ordered from Grand Rapids. Historians first identified this wagon as an 1891 and later as an 1892. However, the first Sintz engines from Grand Rapids were not available until February of 1893, so at very best, the wagon was completed sometime later. The vehicle, which is in the Milwaukee Public Museum, has been restored but it no longer has the Sintz engine.

The Reeves Variable Speed Pulley Co., of Columbus, Indiana, was a successful pulley maker and in 1897 spawned the Reeves Motor Carriage Company of Columbus. They made a motor buggy with a Sintz-type vertical, 2-cylinder, 2-cycle engine. The June, 1897 issue of the

Motorcycle Magazine credited the Sintz engine as having established a performance record. The 6 hp, 2-cycle engine in the Reeves vehicle "has been run over 5,000 miles in the past year." The engine was described as a "vertical type, with two parallel cylinders. The cylinders and water jacket for cooling, are made in one casting."

The distinctive feature of the Reeves vehicle was its speed-varying mechanism. Advertisements states that, "by its use any speed whatever can be obtained between the maximum and the minimum, the range being one to ten."

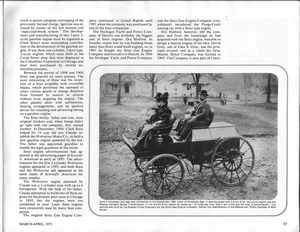

As an apparent trade agreement, the Reeves Company built a four passenger vehicle for the Sintz Gas Engine Company. The car was pictured in the September issue of

Horseless Age which identified it as a Sintz Motor Carriage. It was claimed that the vehicle had a top speed of 12 miles an hour on good roads, and "can climb any hill it encounters."

Many other American automobile pioneers used 2-cycle engines. The Elmore, of 1901 to 1913, was one of the most successful. Among others was the Pambla of Chicago in 1903, which was "convertible" into either a 2-cycle or a 4-cycle type; the Merrill 2-cylinder; the Crown 2-cylinder; Wilcox Bachle, and Dubrie Callie 1905; Simplex of Mishawaka, Indiana, with 40-horsepower, 1906; the Atlas of Springfield, Massachusetts, and the Euclid of 1907; the Bailey 4-cylinder of 1909; the Hines 4-cylinder engine of Cleveland as well as the Duryea Buggaut.

Later the 2-cycle engine for the automobile largely disappeared and today there are only a few.

Sweden's successful Saab uses a 3-cylinder 2-cycle engine. For other applications, however, the use of 2-cycle engines has multiplied tremendously. They are also used as outboard engines in boats, for chain saws, power mowers, blowers, portable power plants, etc.

Most 3-port 2-cycle engines of today use the same basic design which was patented and developed by Clark Sintz of Grand Rapids, Michigan, in 1892 and 1893.

Prior to 1893, many American inventors experimented with the 2-cycle gas engine, but most, including Sintz, utilized an air supply tank in a great variety of forms. One of the earliest patents dates back to 1844.

Lewis Hallock Nash of Brooklyn, New York, a gas engine designer, in his patent of 1888 seems to have been one of the first to conceive a pressured crankcase, but air was admitted by means of an atmospheric operated valve on the side of the crankcase.

Sintz is believed to be the first to patent and manufacture a 2-cycle 3-port engine which utilized crankcase pressure and the piston as the only means for opening and closing the intake and exhaust ports. In his patent application he called it "substantially a valveless engine." In fact, some attempts may have been made to collect royalties from others who used the Sintz principle. The April, 1906, issue of

Cycle and Automobile Trade Journal featured an article by Hugh Dolnar, (real name was H.L. Arnold) one of the best known automobile technical writers of that period. The article was intended to "greatly aid many experimenters who are working wholly in the dark as to what has gone before." It was written with the aid of the files of Parker and Burton, patent lawyers, Detroit. It stated that, "the Sintz 3-port patent (No. 509,255) will expire November 21, 1910, and is owned by Mr. James Whittemore, Detroit, Michigan, said to represent the Olds Motor Works, who is demanding pay from those who have made and are making box pressure 2-cycle motors with the crank box intake port covered and uncovered by the working piston, 3-port style."

Clark Sintz was born May 9, 1950 in Clark County, Ohio on a farm now inside the city of Springfield. His father, Peter Sintz, Jr. was a prosperous farmer who also owned a saw mill and a grist mill. Clark's grandfather, Peter Sintz, was born in Pennsylvania in 1776, settled in a log cabin in Ohio in 1802. Peter Sintz was the son of Nicholas Sintz, an emigrant from Germany.

At the age of 12, young Clark developed a steam engine and by 1868, he had built a slide valve steam engine and he commenced to manufacture it in 1873.

While at the Philadelphia Centennial Exposition of 1876, he became interested in internal combustion engines and began to experiment with them. In 1885, he pioneered a radically different gasoline engine which was so successful he formed the Sintz Gas Engine Company in Springfield, Ohio to produce it.

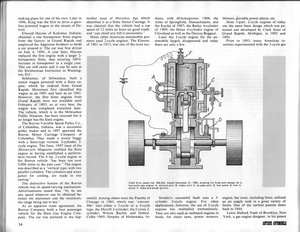

Clark Sintz obtained his first patent, No. 339,225, on April 6, 1886, for "new and useful improvements in gas engines." The 2-cycle engines of this period utilized a pressure tank or "mixing chamber" and the Sintz patent would "avoid the usual mixing chamber" and instead provide a charging and a power cylinder side by side. The piston in the charging cylinder would compress the fuel air mixture and as it reached top dead center, a valve permitted the mixture to pass into the power cylinder where it was ignited. An ingenious link mechanism forced the compressing piston to reach top dead center before the power piston. Ignition was controlled by a sliding valve which was timed to expose a small hole in the head to a flame outside of the cylinder.

Sintz's experiments with gas engines did not stop here. Two years later he was granted a second patent for a 2-cycle engine and it is evident that he had done a lot of work. He wrote that as he had ascertained by trial, "There are several cardinal principles or characteristics which are of primary importance in carrying out this invention. That of exploding the motive agent as the crank is just on or reaching the dead center, so as to partially utilize the explosive force as well as well at the beginning of the stroke as during the full period of the stroke. (This was an anticipation of our present method of spark advance).

"That of closing the exhaust port by the time the piston reached midway its return stroke, for the purpose of allowing the greater portion of the exploded product to escape from the cylinder during the incoming of the new explosive charge.

"That of breaking the electric circuit which furnishes the igniting spark, proportionately quicker, for the purpose, as I have ascertained by trial, of more certainly creating a spark than when the circuit is broken slowly."

The illustration shows a two diameter piston working in an integral two diameter cylinder. The larger piston sucking and forcing air in a separate reservoir from where it is admitted into the working cylinder and ignited. The illustration also shows the adaptation of a magneto in conjunction with a make-and-break ignition system, but no mention is made about its development.

One of these engines was purchased by Addison Barber of Grand Rapids. Barber was so pleased with the performance of the engine that he persuaded Sintz to move his company to that city. In December, 1892, the Sintz company moved to Canal and Front Streets, Grand Rapids, Michigan. Before moving, however, Sintz had already developed a new design and in October, 1892, he made application for the now common, 3-port 2-cycle engine. The patent was issued on November 21, 1893.

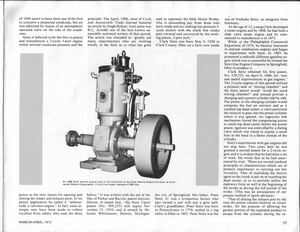

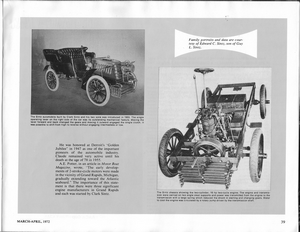

The 3-port Sintz engine of 1893 was a one-cylinder, vertical type, with the cylinder and crankcase cast as a single piece. Main bearing flanges were bolted to each side of the case. The cylinder had a water jacket but the flat plate head did not. Briefly it worked as follows: As the piston moved upward it created a vacuum in the crankcase and as it neared top dead center, the skirt of the piston uncovered a port on the side of the cylinder permitting air to rush into the crankcase. On its downward stroke the piston closed this port and compressed the air in the crankcase. As the piston neared bottom dead center, it uncovered the exhaust port releasing the previously burnt gas, then it uncovered a third port permitting the compressed crankcase air to pass to the top of the piston. An accentric on the crankshaft operated a small fuel pump and fuel was injected into the air as it rushed to the top of the cylinder. A deflector bolted to the top of the piston directed the new charge upward to assure complete scavenging of the previously burned charge. Ignition was attained by means of the low tension coil "make-and-break system." The development and manufacturing of this 3-port 2-cycle gasoline engine must be regarded as Clark Sintz's most outstanding contribution to the development of the gasoline engine. It was these one cylinder, 3-port type, 2-cycle engines which were built at the Canal Street shop that were displayed at the Columbian Exposition in Chicago and later were purchased by several automobile pioneers.

Between the period of 1894 and 1900 Sintz was granted six more patents. The most interesting of these was his was his invention of a boat propeller with reversible blades, which permitted the operator to select various speeds or change direction from forward to neutral to reverse without even stopping the engine. The other patents dealt with carburetion, bearing arrangements, and an ignition device for retarding and advancing timing on a gasoline engine.

The Sintz family, father and sons, were original thinkers and, when things didn't go right with one company, they started another. In December, 1894, Clark Sintz helped his 19 year old son, Claude, establish the Wolverine Motor Co., to built a new gasoline engine, patented by the son. The father was appointed guardian to handle the legal questions of the minor.

Sintz engine advertisements had appeared in the advertising pages of

Scientific American as early as 1893. The advertisement for the first 2-cylinder Wolverine engines appeared in 1985, and both Sintz and the Wolverine ads appeared in the same issues of

Scientific American for many months.

The Wolverine engine patented by Claude was a 2-cylinder type with up to 6 horsepower. With the help of his father, Claude attempted to build two of these engines for the pioneer auto races in Chicago in 1895, but the engines were not completed in time. Later these engines were extensively used by many boat companies.

The original Sintz Gas Engine Company continued in Grand Rapids until 1901 when the company was purchased by one of the boat companies.

The Michigan Yacht and Power Company of Detroit was probably the biggest user of Sintz engines. Ora Mulford, its founder, stated that he was building boats faster than Sintz could build engines, so, in 1901 he bough the Sintz Gas Engine Company and moved it to Detroit. In 1904 the Michigan Yacht and Power Company and the Sintz Gas Engine Company (consolidated) introduced the Pungs-Finch touring car with a Sintz type engine.

Ora Mulford, however, left the company and from the knowledge he had acquired with the Sintz engine, was able to design a marine engine of his own. David Gray, son of John S. Gray, was the principal investor and as a result the Gray Marine Motor Company was formed in 1905. The company is now part of Continental Motors Corporation.

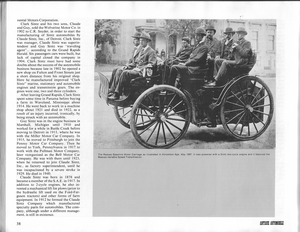

Clark Sintz and his two sons, Claude and Guy, sold the Wolverine Motor Co. in 1902 to C.R. Snyder, in order to start the manufacturing of Sintz automobiles by Claude Sintz, Inc., of Detroit. Clark Sintz was manager, Claude Sintz was superintendent and Guy Sintz was "traveling agent"... according to the Grand Rapids Herald. Six passengers cars were built, but lack of capital closed the company in 1904. Clark Sintz must have had some doubts about the success of the automobile business because late in 1902 he opened a new shop on Fulton and Front Streets just a short distance from his original shop. Here he manufactured improved "Clark Sintz" marine, stationary and automobile engines and transmission gears. The engines were one, two and three cylinders.

After leaving Grand Rapids, Clark Sintz spent some time in Panama before buying a farm in Waveland, Mississippi about 1914. He went back to work in a machine shop about 1921 and died in 1922, as a result of an injury incurred, ironically, by being struck with an automobile.

Guy Sintz was in the engine business in Marshall, Michigan until 1910 and worked for a while in Battle Creek before moving to Detroit in 1911, where he was with the Miller Motor Car Company. In 1915, he moved to Pittsburgh to join the Pennsy Motor Car Company. Then he moved to York, Pennsylvania in 1917 to work with the Pullman Motor Company, later reorganized as the Bell Motor Car Company. He was with them until 1923, when he returned to join Claude Sintz, Inc., as a factory superintendent, until he was incapacitated by a severe stroke in 1929. He died in 1940.

Claude Sintz was born in 1878 and became a member of the S.A.E. in 1917. In addition to 2-cycle engines, he also invented a mechanical lift for plows (prior to the hydraulic lift used on the Ford-Ferguson tractors) and other forms of farm equipment. In 1912 he formed the Claude Sintz Company which manufactured specialty parts for automobiles. The company, although under a different management, is still in existence.

He was honored at Detroit's "Golden Jubilee" in 1947 as one of the important pioneers of the automobile industry. Claude remained very active until his death at the age of 78 in 1955.

A.E. Potter, in an article in

Motor Boat Magazine, wrote, "The early developments of 2-stroke-cycle motors were made in the vicinity of Grand Rapids, Michigan, gradually extending toward the Atlantic seaboard." The importance of this statement is that there were three significant engine manufacturers in Grand Rapids and each was started by Clark Sintz.