|

By accessing or using The Crittenden Automotive Library™/CarsAndRacingStuff.com, you signify your agreement with the Terms of Use on our Legal Information page. Our Privacy Policy is also available there. |

Volvo has made a huge step in battery technology for electric cars

|

|---|

|

|

Volvo has made a huge step in battery technology for electric cars

Matt Hubbard

Speedmonkey

October 17, 2013

Volvo has come up with a new battery technology that, if it works, could revolutionise electric cars.

Volvo is on something of a roll at the moment. Not content with building a new plant for eco engines, aiming to build cars that won't kill anyone or anything ever and showing the pretty P1800 concept, now they've come up with a new battery technology that's light years ahead of anyone elses.

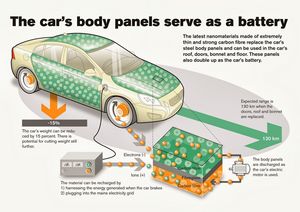

The technology is a material that uses carbon fibres, nano structured batteries and super capacitors and actually replaces body panels. The replacement panels store electricity and are lighter and stronger than steel panels.

The batteries (super capacitors) themselves you can see below. They are flat, foil wrapped bags that are sandwiched between carbon fibre and polymer resin to form the panels. These can replace the boot lid, bonnet, roof, doors and wheel well.

The material charges faster than conventional batteries whilst being strong and flexible.

Don't forget, a Tesla Model S essentially uses thousands of standard batteries which form the floor of the car. A Model S weighs 2,108kg whereas a similar size and shape BMW 530d weighs 1,770kg.

Volvo has been testing its new material on an S80 with a conventional engine. They have replaced the Stop/Start battery with a bootlid and plenum using the new material. The additional strength in the plenum has also meant they could do away with the 'rally bar', a structural component. The new set-up is 50% lighter than the battery and rally bar, and provides enough power for the car's entire 12 volt system.

Volvo believe that by replacing an electric car's standard batteries with the new material it could reduce weight by at least 15%, with resultant improvements in performance.