Consumer Information Regulations; Federal Motor Vehicle Safety Standards; Rollover Prevention |

|---|

Topics: National Highway Traffic Safety Administration

Topics: National Highway Traffic Safety Administration

|

Barry Felrice

Federal Register

28 June 1994

[Federal Register: June 28, 1994]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 575

[Docket No. 91-68; Notice 03]

RIN 2127-AC64

Consumer Information Regulations; Federal Motor Vehicle Safety

Standards; Rollover Prevention

AGENCY: National Highway Traffic Safety Administration (NHTSA), DOT.

ACTION: Notice of proposed rulemaking (Consumer Information

Regulation); Termination of rulemaking (Federal Motor Vehicle Safety

Standard).

-----------------------------------------------------------------------

SUMMARY: As part of its comprehensive efforts to address the problem of

light vehicle rollover, this agency is proposing a new consumer

information regulation that would require that passenger cars and light

multipurpose passenger vehicles and trucks be labeled with information

about their resistance to rollover. This information would enable

prospective purchasers to make choices about new vehicles based on

differences in rollover risk; motivate manufacturers to give more

priority to rollover stability in designing their vehicles; and inform

motorists that they can reduce the risk of injury in a rollover by

wearing their safety belts. NHTSA believes that this would reduce the

number of injuries and fatalities from rollover accidents.

DATES: Comment Date: Comments must be received by August 29, 1994.

ADDRESSES: Comments should refer to the docket and notice number of

this notice and be submitted to: Docket Section, Room 5109, National

Highway Traffic Safety Administration, 400 Seventh Street, SW.,

Washington, DC 20590. (Docket Room hours are 9:30 a.m.-4 p.m., Monday

through Friday.)

FOR FURTHER INFORMATION CONTACT: Gayle Dalrymple, Office of Vehicle

Safety Standards, NRM-11, National Highway Traffic Safety

Administration, 400 Seventh Street, SW., Washington, DC 20590.

Telephone: (202) 366-5559.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. The Rollover Crash Problem

II. Relationship to Other Agency Activities

A. Agency Efforts to Address the Rollover Crash Problem

B. Consumer Information Activities

III. Background

A. Statutory Requirement for Rulemaking

B. ANPRM and the Planning Document

C. Comments on the ANPRM and the Planning Document

IV. Summary

A. Summary of Agency Decision Not to Propose a Vehicle Standard

B. Summary of Proposed Consumer Information Regulation

V. Agency Analysis of the Vehicle Stability Metrics

A. Identification of Vehicle Stability Metrics

B. Analysis of Importance of Factors

1. Additional Analyses since the ANPRM

2. Predictive Power of the Metrics

VI. Decision Not to Propose a Vehicle Stability Standard

A. Estimates of the Benefits of a Standard

1. Rollover Risk Reduction

2. Predicted Single Vehicle Accident Rate

3. Injury/Fatality Rate Reduction

B. Estimates of the Costs of a Standard

C. Conclusions

VII. Proposed Consumer Information Regulation

A. Rationale

B. Proposed Label

C. Stability Metrics

1. Critical Sliding Velocity

2. Tilt Table Angle

D. Timing of Information Provided by the Manufacturers and NHTSA

E. Benefits

F. Costs

VIII. Final Stage Manufacturers and Alterers

IX. Rulemaking Analyses and Notices

A. Executive Order 12866 and DOT Regulatory Policies and

Procedures

B. Regulatory Flexibility Act

C. Paperwork Reduction Act

D. National Environmental Policy Act

E. Executive Order 12612 (Federalism)

F. Civil Justice Reform

X. Effective Date of Final Rule

XI. Submission of Comments

I. The Rollover Crash Problem

Rollover crashes occur for many reasons, and involve the

interaction of a variety of factors including the driver, the roadway,

the vehicle, and environmental conditions. The relationship of these

various factors to rollover crashes can be examined by analyzing data

from various sources.

The agency estimates that there were 220,000 rollover crashes

involving passenger cars, and multipurpose passenger vehicles and

trucks under 4,536 kilograms (10,000 pounds) gross vehicle weight

rating (collectively, ``light trucks'') in 1991. These resulted in

9,186 fatalities; 56,000 occupants of these vehicles received serious,

incapacitating injuries. These numbers have remained relatively

constant over the past six years. Ejections are responsible for 63

percent of the fatalities. Safety belts are used by only 13 percent of

the fatally injured occupants.

Of the 220,000 rollover crashes, 207,000, or 94 percent, were

single vehicle crashes and 192,000 of these, or 93 percent, occurred

off the road. Various accident studies have indicated that loss of

vehicle directional control is a prelude to rollover in 50 percent to

80 percent of all rollover crashes.

For the years 1985-1991, small cars had the greatest number of

rollover fatalities, followed by standard-size pickup trucks. However,

pickup trucks and sport utility vehicles have fatality rates per

million registered vehicles between two and three times as great as

that of passenger cars. The difference between the numbers of rollover

fatalities and the rollover fatality rates for particular vehicle types

is a result of the relative proportions of various types of vehicles in

the fleet. There are currently many more small cars than pickup trucks

and sport utility vehicles on the road today.

(A more extensive discussion of rollover statistics, and the

sources for this information, can be found in the ``Addendum to

Technical Assessment Paper,'' NHTSA 1994, which is in Docket No. 91-68,

Notice 03.)

II. Relationship to Other Agency Activities

A. Agency Efforts To Address the Rollover Crash Problem

The agency believes that no single type of rulemaking or other

agency action could solve all, or even a majority of, the problems

associated with rollover. Accordingly, it is pursuing a broad range of

actions to address those problems.

First, NHTSA has published an NPRM to reduce the potential for

injuries to the head from contact with upper interior components (58 FR

7506, February 8, 1993). The comment period was reopened to December 1,

1993 (58 FR 54099, October 20, 1993) and a public hearing was held on

November 15, 1993. As explained in the Addendum to Technical Assessment

Paper, NHTSA's research indicates that head injuries are the most

prevalent type of injury associated with rollovers. The agency expects

to issue a final rule on this subject in late 1994.

Second, with respect to anti-lock brake systems, the agency has

published an advance notice of proposed rulemaking (ANPRM) for light

duty vehicles (January 4, 1994, 59 FR 281). (``Light duty vehicles''

include cars, vans, pickup trucks and sport utility vehicles with a

gross vehicle weight rating of 4,536 kilograms (10,000 pounds) or

less.) Since most vehicles involved in rollovers lose their

longitudinal stability before leaving the roadway, where they then trip

and roll over, and since anti-lock brake systems are designed to

enhance the longitudinal stability of a vehicle, a requirement for

anti- lock brakes could reduce the number of rollovers. NHTSA's

preliminary evaluation of rear-wheel anti-lock brake systems, the type

of anti-lock brakes most often found on light trucks, indicates that

anti-lock brakes on light trucks are effective in reducing the number

of nonfatal single vehicle accident rollovers for almost every type of

truck, under any type of road condition. Reductions of single vehicle

accident rollovers were typically in the range of 30 percent to 40

percent. NHTSA is continuing to analyze the data and a comprehensive

report of the findings will be published at a later date. (The

preliminary evaluation is available in Docket No. 70-27-GR-026.)

Third, as noted above, ejections are a frequent occurrence in fatal

rollover crashes. To attempt to reduce the frequency of ejections, the

agency is conducting research on glass/plastic side windows and

improved door latches. Preliminary research results should be available

within the next year to enable NHTSA to determine if rulemaking should

be pursued in these areas.

Fourth, the agency is conducting research on improvements to

vehicles' roof strength that could reduce head and neck injuries. A

decision whether to begin rulemaking on this subject is expected in

1994.

Fifth, as noted above, safety belt use is very low among persons

fatally or seriously injured in rollover crashes. NHTSA promotes

increased use of safety belts through public awareness and education

efforts and by supporting the implementation and enforcement of state

safety belt use laws. Agency occupant protection awareness and

education activities include national media campaigns; outreach through

national health, medical, civic, and intergovernmental organizations;

and, administration of Section 402 state highway safety program funds.

The agency promotes effective state safety belt usage laws by

conducting evaluation studies and demonstration projects, training law

enforcement personnel, and by administering the Section 153 state

incentive grant program.

In addition, NHTSA has contracted with the Advertising Council to

prepare two ``Vince and LarrySM'' (the agency's safety belt

``spokespersons'') public service announcements (PSAs) for television,

and one ``Vince and LarrySM'' PSA for radio, on the specific

benefits of safety belts in rollover crashes. One of the television

PSAs and the radio PSA were available at the end of March, 1994. The

other television PSA will be available approximately six months later.

These safety belt initiatives will supplement the other actions to

address the rollover problem.

Sixth, it is well known that rollover crashes have a high incidence

of alcohol involvement. The agency has numerous programs and activities

aimed at reducing alcohol-related crashes, injuries, and fatalities,

which follow two fundamental strategies: information-education (such as

Advertising Council PSAs on television) and laws-enforcement-sanctions

(such as .08 BAC, sobriety checkpoints, and increasingly severe

sanctions for repeat offenders). Section 410 grants to states provide

incentives to states to use these strategies. These combined strategies

have been effective as alcohol-related fatalities have decreased 30

percent over the past 10 years.

Seventh, and finally, the agency is issuing this notice regarding

vehicle stability requirements and consumer information.

B. Consumer Information Activities

NHTSA believes that consumer and manufacturer behavior can be

affected through the provision of consumer information regarding

vehicle safety. The agency's experience with the New Car Assessment

Program (NCAP) demonstrates the power of consumer information. Under

the NCAP Program, the agency tests the ability of vehicles to protect

their front seat occupants in frontal crash tests. The tests are

similar to those conducted under Standard No. 208, Occupant Protection,

to determine whether vehicles meet the Standard's injury criteria,

except that the Standard's tests are conducted at 30 mph, while NCAP

tests are conducted at 35 mph. Several manufacturers have informed the

agency that they view it as important to perform well in the NCAP

tests, even though there is no regulatory requirement to do so. The

decline in the injury scores in NCAP tests over time for all

manufacturers, as reported in ``Report on the Historical Performance of

Different Auto Manufacturers in the New Car Assessment Program Tests,''

NHTSA, August 1993, can also be attributed partially to NCAP.

The agency believes that further safety improvements could be

gained through providing consumers with information about additional

aspects of new vehicle safety performance. NHTSA recently conducted a

series of 15 focus groups, comprised of members of the public, to

examine the type and format of desired consumer information about

vehicle safety. (See ``Focus Groups on Traffic Safety Issues: Public

Response to NCAP,'' S.W. Morris & Company, Inc., August 1993, which can

be found in Docket No. 79-17, Notice 01, or ``New Car Assessment

Program--Response to the NCAP FY 1992 Congressional Requirements,''

Report to the Congress, December 1993, which can be found in Docket No.

97-17, Notice 39). One of the topics examined was the current NCAP and

how it could be improved. In response to the results of the focus group

work, the agency has changed the format for NCAP test results. The new

format responds to consumer demand for reporting results in a way that

is less technical and easier to understand.

The focus groups also indicated that the agency's consumer safety

information activities should be expanded to include additional kinds

of crashes, including side impacts and rollovers. The potential

importance of providing broader safety information about new light duty

vehicle performance can be seen from figures regarding the proportion

of fatalities in each of the three most important types of crashes. In

1991, frontal crashes accounted for 39 percent of all fatalities

involving light duty vehicle occupants, rollover crashes for 30

percent, and side impact crashes for 25 percent. Together, these three

types of crashes account for 94 percent of all fatalities. Information

on performance in all three types of crashes could provide consumers

with a comprehensive, balanced picture of the safety of new vehicles.

As part of its efforts to expand its consumer safety information

programs, NHTSA has sought participation and guidance from the general

public on the types and format of safety information to be provided to

consumers. On January 3, 1994, the agency published a request for

comments on whether to supplement the agency's efforts by holding a

public meeting to discuss, among other items, the expansion of the NCAP

program to other crash modes (59 FR 104).

Based on the foregoing, the agency plans to supplement this

rollover proposal with a future proposal for requiring that each new

vehicle have a window sticker providing information not only on vehicle

rollover resistance, but also on frontal and side impact crash

performance.

III. Background

A. Statutory Requirement for Rulemaking

The NHTSA Authorization Act of 1991 (the Act) (part of the

Intermodel Surface Transportation Efficiency Act) requires the agency

to address several vehicle safety subjects through rulemaking. One of

the subjects, set forth in section 2503(1), is protection against

unreasonable risk of rollovers of passenger cars, multipurpose

passenger vehicles, and trucks with a gross vehicle weight rating of

8,500 pounds or less and an unloaded vehicle weight of 5,500 pounds or

less.

Section 2502(b)(2)(A) of the Act required that NHTSA publish, no

later than May 31, 1992, an ANPRM or a notice of proposed rulemaking

(NPRM) on this subject. The January 3, 1992, ANPRM fulfilled this

mandate.

Section 2502(b)(2)(B)(i) of the Act provides that the agency must

complete a rulemaking action on rollover within 26 months of publishing

the ANPRM. The ANPRM was published on January 3, 1992; thus, this

rulemaking action was to have been completed by March 3, 1994. Section

2502(b)(2)(B)(ii) of the Act provides that this rulemaking will be

considered completed when NHTSA either publishes a final rule or

decides and announces that it is not promulgating a rule.

B. ANPRM and Planning Document

NHTSA announced in its January 3, 1992 ANPRM on the rollover

problem that it was considering various regulatory actions to reduce

the frequency of vehicle rollovers and/or the number and severity of

injuries resulting from vehicle rollovers (57 FR 242). The agency

requested comments on potential regulatory actions in the areas of: (1)

Improved stability; (2) improved crashworthiness; and (3) consumer

information. NHTSA said that it might issue a rule or rules in any one

of these three categories, or in any combination of them.

The ANPRM discussed the agency's statistical analyses of the

interaction of driver characteristics, vehicle stability metrics,

roadway and environmental conditions. The notice described the

following vehicle stability metrics as having a potentially significant

role in vehicle rollover: center of gravity height; static stability

factor; tilt table ratio; side pull ratio; wheelbase; critical sliding

velocity; rollover prevention metric; braking stability metric; and

percent of total vehicle weight on the rear axle. A vehicle stability

metric is a measured vehicle parameter that presumably is related to

the vehicle's likelihood of rollover involvement. To supplement the

ANPRM, a Technical Assessment Paper that discussed testing activities,

testing results, accident data collection, and analysis of the data was

placed in the docket on January 6, 1992. A description of the

individual metrics can be found in the Technical Assessment Paper.

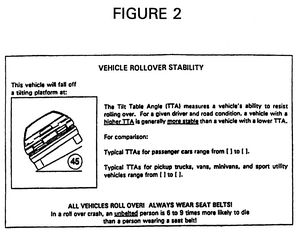

(Note: For the remainder of this notice, ``tilt table angle'' is

used in place of ``tilt table ratio,'' regardless of the term used

in any other document. NHTSA is using ``tilt table angle'' because

the agency is proposing tilt table angle as one of the possible

measurements to be used in the proposed consumer information

regulation. Tilt table angle is the angle at which the last uphill

tire of a vehicle lifts off a tilting platform. Tilt table ratio is

the tangent of the tilt table angle and is believed to be harder for

the average consumer to understand.)

During the development of the ANPRM and subsequent to receiving and

analyzing comments to the ANPRM, it became obvious that no single type

of rulemaking could solve all, or even a majority of, the problems

associated with rollover. This view was strengthened by the agency's

review and analysis of the comments on the ANPRM. To emphasize this

conclusion and inform the public further about the complicated nature

of the light duty vehicle rollover problem, the agency released a

document titled ``Planning Document for Rollover Prevention and Injury

Mitigation'' at a Society of Automotive Engineers meeting on rollover

on September 23, 1992. The Planning Document gave an overview of the

rollover problem and a list of alternative actions that NHTSA was

examining to address the problem. Alternatives for regulatory action

and a schedule for decisions on each were included. The current status

of the presented alternative actions was discussed earlier in this

notice. The document was placed in Docket No. 91-68; Notice 02, on the

same day. NHTSA published a notice in the Federal Register announcing

the availability of the Planning Document and requesting comment

(September 29, 1992; 57 FR 44721).

C. Comments on the ANPRM and the Planning Document

Forty-two comments concerning the ANPRM and the Planning Document

were received. A Summary of Comments was placed in the docket on

September 15, 1993. Ten commenters addressed the Planning Document,

eight of whom had also commented on the ANPRM. Responses to the

Planning Document, for the most part, were abridged forms of the

commenters' responses to the ANPRM.

All the commenting vehicle manufacturers asserted that, while

stability metrics are statistically related to the rates with which

single vehicle accidents result in rollovers, they are not causally

related to rollover. Therefore, the manufacturers asserted, the agency

cannot issue a regulation based on any one of these metrics solely

because of its statistical correlation with accident data. Automotive

Testing, BMW, Ford, GM, the American Automobile Manufacturers

Association (AAMA, then known as the Motor Vehicle Manufacturers

Association), and VW claimed that stability metrics are insufficient by

themselves to explain a vehicle's degree of involvement in rollover

crashes. These commenters stated that driver and environmental factors

outweigh the contributions of vehicle factors to the likelihood of a

single vehicle accident becoming a rollover. Nevertheless, most

commenters addressed the relevancy of several of the individual metrics

the agency considered for a vehicle stability rulemaking.

Tilt table angle, one of the metrics being proposed in this notice,

appeared to be more acceptable to the commenters than the other

stability metrics. While side pull ratio was favored by Automotive

Testing, Chrysler, GM, and Nissan, all these commenters also commented

favorably on aspects of tilt table angle. Static stability factor was

favored by only Perrone Forensic Consulting, who also commented

favorably on tilt table angle. All other commenters who indicated a

preference among the metrics discussed in the ANPRM favored tilt table

angle. However, Chrysler, Ford, GM, Isuzu, and VW claim vehicle changes

made to improve a vehicle's tilt table performance may degrade a

vehicle's control and handling attributes. Chrysler said that the

repeatability of results from the tilt table procedure was unknown. On

the other hand, Advocates for Highway and Auto Safety, the

International Organization of Motor Vehicle Manufacturers, and GM

stated they believe that the procedure is repeatable. Chrysler and AAMA

also commented that the tilt table test is not a standard practice and

its measurement error has not been established.

Commenters did not respond directly to the idea of using critical

sliding velocity, which is also being proposed for use in this notice.

However, most manufacturers commented that center of gravity height (a

measurement necessary to calculate critical sliding velocity) is

difficult to measure and that the measurement is not repeatable.

Therefore, according to these commenters, any metric which uses center

of gravity height would be impracticable.

The commenters also focussed on crashworthiness improvements. By

far the most favorable crashworthiness countermeasure cited by the

commenters was increased seat belt use to prevent ejections. In

general, commenters believe that more benefits could be gained through

increased seat belt use than through any vehicle related

crashworthiness or crash avoidance countermeasure. Some commenters also

favored improved roof structures including roll bars or cages, but

Ford, GM, Nissan, and VW believe the installation of a roll bar or cage

raises the vehicle's center of gravity and decreases rollover

stability. Other suggestions were for improved glazing, improved latch/

lock/hinge systems for doors, anti-lock brakes, bumper height

regulations, removal of drunk and otherwise impaired drivers from the

road, stricter enforcement of speed limits, and improved public

awareness of the causes of rollover crashes as ways to reduce rollover

casualties.

Finally, Chrysler, GM, AAMA, and Toyota claimed that labeling

vehicles with a stability metric would be simplistic and could mislead

consumers, giving them a false sense of security in a vehicle labeled

with a high stability metric (i.e., a metric indicating comparatively

high resistance to rollover). These commenters believe that consumers

could consider the metric to be an absolute measure of rollover

likelihood, regardless of driver behavior or roadway conditions.

IV. Summary

A. Summary of Agency Decision Not To Propose a Vehicle Standard

In analyzing whether to proceed with a vehicle stability

rulemaking, the agency identified several criteria that had to be met

before proposing a safety standard. First, the identified vehicle

metrics had to have a causal relationship to the likelihood of

rollover. For example, center of gravity height affects rollover

likelihood; the color of the vehicle does not. Second, the metric had

to have a statistical relationship to rollover frequency. Third,

improvement in the metric should result in significant safety benefits

at a reasonable cost without having the effect of necessitating the

radical redesigning of one or more types of vehicles. As discussed

below, the agency identified two metrics that met the first two

criteria, but not the third.

To determine whether it was appropriate to propose a new vehicle

safety standard, NHTSA examined the complex interactions between driver

behavior, vehicle properties, and roadway characteristics which result

in rollovers. The suitability of a vehicle safety standard based on

rollover stability depends on the importance of rollover stability, as

represented by a vehicle metric, relative to other rollover influences,

such as vehicle handling properties, vehicle condition, the nature of

the roadway and shoulder terrain, and driver behavior. The agency

sought to determine whether vehicle stability metrics are significant

variables in a statistical model of the risk of rollover. If they are,

then a standard regulating stability might be justified, depending on

the results of a comparison of benefits and costs for such a standard.

After analyzing a number of static and dynamic rollover metrics,

the agency concluded that two vehicle metrics, tilt table angle and

critical sliding velocity, can account for about 50 percent of the

variability in rollover risk in single vehicle accidents, after

considering driver, roadway, and environmental factors. (Rollover risk

is the number of single vehicle rollovers involving a particular make/

model divided by the number of single vehicle crashes of all types

involving the same make/model.) This statistical analysis was conducted

on all light duty vehicles treated as a group. However, analysis of

accident data indicated that certain subgroups of light duty vehicles

are more likely to roll over than other subgroups. For example, sport

utility vehicles and compact pickup trucks tend to be the most likely

vehicles to roll over. Large passenger cars tend to be the least likely

to roll over. The importance of this difference is that if significant

benefits are to be achieved, then changes in the metric should be made

that affect passenger cars since nearly 60 percent of rollover

fatalities occur in those vehicles.

The agency's analysis showed that setting a performance level high

enough to affect passenger cars, would require redesign of nearly all

sport utility vehicles, vans, and pickup trucks. Using a single value

of one of these metrics as the performance standard for all light duty

vehicles would have resulted in the radical redesign of the

characteristics many, and in some cases all, vehicles of certain

classes. That degree of redesign would have raised issues of public

acceptance and possibly even the elimination of certain classes of

vehicles as they are known today.

To avoid this consequence, the agency then examined whether several

values for these metrics, each applying to a different class of

vehicles (e.g., one value for passenger cars and a different value for

light trucks) would be feasible. Since the statistical analyses

discussed above were conducted on all light duty vehicles treated as a

group, it was necessary to determine whether either of the stability

metrics exhibited sufficiently high levels of correlation to assure the

agency that a requirement applying to only one class of vehicle would

be expected to reduce the incidence of rollovers for vehicles in that

class. As explained later in this notice, the agency found that the

statistical correlations of the metrics with rollover accident data

within a class of vehicles was not so consistent as for all vehicles

grouped together. This weakening of the predictive ability of the

metric is, to some extent, the result of the smaller range of the

metric within any class of vehicles together with the inherent

variability in the data. Based on this analysis, and the general

analysis of costs and benefits discussed later, the agency determined

that proposing a standard specifying one minimum stability value for

cars and others for various classes of light trucks could not be

justified.

The agency also determined that, considering the costs and benefits

involved, proposing a safety standard specifying a single minimum

stability value for both cars and light trucks could not be justified.

While light trucks have lower stability measurements than cars do, the

greatest number of rollover-related deaths and injuries occur in

passenger cars because of their larger population size. Therefore, if

the agency wished to set a stability minimum high enough to realize

significant reductions in the number of fatalities in all light duty

vehicles, it would have to set the minimum above the stability number

of most light trucks. The costs of such a standard, in terms of the

cost of vehicle redesign and the loss of consumer-desired attributes,

were determined to be very high, as entire classes of light trucks

would probably need to be substantially redesigned to meet such a

standard. This redesign could result in the elimination of some vehicle

types, e.g., sport utility vehicles, as they are known today.

Based on this analysis, NHTSA has decided not to propose a vehicle

stability rule, and is deferring any further action on this subject

until such time as information becomes available demonstrating the cost

effectiveness of such a rule. The agency may reinitiate such a

rulemaking upon receipt of such information. This termination of

rulemaking on vehicle stability fulfills the statutory mandate of

section 2502(b)(2)(B)(i). However, through the consumer information

proposal being published today, and the other actions mentioned above,

NHTSA is continuing to take a comprehensive approach to reducing

rollover casualties.

B. Summary of Proposed Consumer Information Regulation

While NHTSA is terminating rulemaking on a vehicle stability

standard, NHTSA believes that the correlation between stability and

rollover risk is significant enough to justify proposing a consumer

information regulation to relieve the possibility of uninformed risk.

The agency believes that informing consumers of the relative resistance

of different vehicles to rollover will influence consumers to purchase

more stable vehicles and encourage manufacturers to improve the

stability of their vehicles. The agency believes that these results are

possible based on its assessment of how consumers and manufacturers

reacted to the provision of frontal crashworthiness information through

the New Car Assessment Program.

The consumer information regulation being proposed by the agency

would require manufacturers of passenger cars and light trucks to label

their vehicles with information relating to rollover stability. To that

end, manufacturers would be required to report a stability metric for

each vehicle make/model to NHTSA by January 1 of each year.

Manufacturers would decide how to group vehicle make/models for the

purpose of reporting stability metrics for those groups. To ensure that

the information is neither understated nor overstated, the reported

stability metric would be measured with a specified procedure and an

accuracy tolerance on reported data would be required. NHTSA would use

the information reported by manufacturers to provide the manufacturers

with the ranges of metrics for both passenger cars and light trucks by

April 1 of each year. For comparison purposes, these ranges would be

included on vehicle labels.

New vehicles manufactured after September 1, 1996 would be required

to have a prescribed window label listing the metric of the labeled

vehicle, the range of that metric for cars and the range for light

trucks. In addition, prescribed language on the label would explain the

significance of the metric, warn consumers that all vehicles can and do

roll over, and remind consumers to always wear seat belts. The proposed

regulation would also require manufacturers to include the information

on the vehicle label in the vehicle's owner's manual.

The agency requests comment on whether or not the proposed vehicle

label should be a permanent sticker, in addition to the window label

which would be removed after first sale. If a commenter believes the

label should be permanent, NHTSA requests comment on whether the

permanent sticker should be required on all vehicles, or only some

subset of vehicles with lower rollover stability. Finally, NHTSA

requests suggestions on placement and size of a permanent sticker. A

permanent sticker would be useful to purchasers of used vehicles and

drivers of rental vehicles.

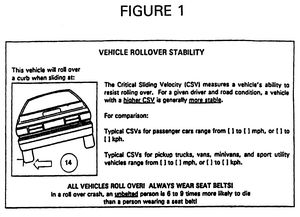

NHTSA is considering two metrics for providing information

regarding rollover stability: critical sliding velocity and tilt table

angle. Critical sliding velocity is a measure of the minimum lateral

(sideways) vehicle velocity required to initiate rollover when the

vehicle is tripped by something in the roadway environment, e.g., a

curb. Tilt table angle is the angle at which the last uphill tire of

the vehicle lifts off a platform as the platform is increasingly

tilted.

NHTSA is proposing two different options for specifying stability

information using these metrics. First, NHTSA may select one of the two

metrics to appear on the label. For example, if the agency selected

tilt table angle, it would require that the specific angle for each

vehicle be shown on its label. Second, NHTSA may require the label to

include a nonquantitative statement concerning the vehicle's rollover

resistance based on one or both of the metrics. For example, instead of

stating a specific angle, the label might use symbols such as one, two,

or three stars.

V. Agency Analysis of the Vehicle Stability Metrics

A. Identification of Vehicle Stability Metrics

The agency has concluded that the two metrics with the best

correlation to accident statistics are tilt table angle, a static

measurement, and critical sliding velocity, a metric calculated from

static and dynamic vehicle measurements and expressed as velocity,

i.e., units of feet per second, miles per hour, or kilometers per hour.

Tilt table angle includes the influences of the vehicle's mass,

center of gravity height, track width, and suspension movement, all of

which are physically related to rollover stability. Because it does not

require an independent measurement of center of gravity height, it is

more practicable, less costly, and more repeatable than most static

rollover metrics.

Critical sliding velocity includes the roll moment of inertia as

well as the various static factors mentioned above in its calculation.

The Technical Assessment Paper found critical sliding velocity alone to

have less correlation with rollover accident statistics than tilt table

angle, but found it to be a statistically significant addition to a

model already containing tilt table angle. However, an error in the

computation of critical sliding velocity was made in the Technical

Assessment Paper. When the logistic regression was repeated with the

correct critical sliding velocity values and data for more vehicle

make/models and additional accident years, NHTSA found the correlation

of critical sliding velocity to accident statistics for all light duty

vehicles grouped together and for the light truck and passenger car

categories to be better than that for tilt table angle. The Addendum to

Technical Assessment Paper contains the corrected analysis.

B. Analysis of Importance of Factors

1. Additional Analyses Since the ANPRM

Since the ANPRM, new vehicles have been added to the data base and

their metrics measured. Several make/models have been tested in

different configurations to determine the range of metrics within a

make/model, given the different available original equipment options.

Also included are several make/models of trucks and vans with anti-lock

brakes as standard equipment and several make/models of high sales

volume passenger cars equipped with anti-lock brakes. A complete list

of all vehicles measured to date, their tilt table angles and critical

sliding velocities, and the ratio of the number of rollovers involving

a particular vehicle model to the number of single vehicle accidents

involving the same model (RO/SVA) in Michigan from 1986 through 1990

can be found in Docket 91-68, Notice 2.

2. Predictive Power of the Metrics

The agency performed two types of analyses attempting to separate

the influence of driver characteristics, road, and environmental

variables in the accident data so that the effect of vehicle rollover

stability could be isolated. A logistic regression analysis

individually considered every accident in a very large data base. Make/

models represented in a great number of accidents influenced the

results more than make/models with fewer accidents. A linear regression

analysis was also done on the rollover risk of make/models, adjusted

for differences in driver and road characteristics within their

individual accident data bases, but not weighted by differences in

accident numbers. The two analyses are discussed in detail in the

Addendum to Technical Assessment Paper.

These analyses were conducted using three statistical models: (a) A

model containing only driver, roadway, and environmental

characteristics; (b) a model containing driver, roadway, and

environmental characteristics, and critical sliding velocity; and (c) a

model containing driver, roadway, and environmental characteristics,

and tilt table angle. For the purposes of comparison, the analyses were

limited to accidents involving those make/models for which the agency

had both tilt table angle and critical sliding velocity data. This

results in an equal number of accidents, or observations (88,397), in

each statistical model.

The logistic regression predicts whether a single vehicle accident

will be a rollover based on the factors in a particular model. Then the

predicted outcomes of the individual accidents are compiled to predict

a rollover risk (rollovers per single vehicle accident) for each of the

128 make/models for which the agency has data on both metrics. This

predicted risk is then compared to the actual risk known from accident

data on these make/models. Two numbers are presented in the table below

for each of the statistical models. The first is the percent

variability explained by the comparison of the rollover risk predicted

by the logistic regression model and the actual rollover risk. The

second number is the percentage of the variability unexplained by the

model containing only driver, roadway, and environmental

characteristics which is explained by the addition of either tilt table

angle or critical sliding velocity. For example, the driver/road/

environmental model leaves 77 percent of the variability in the data

unexplained; 23 percent is explained. When tilt table angle was added

to the model to represent vehicle stability, 65 percent of the

variability in rollover risk was explained. The difference between the

77 percent unexplained variability in the driver/road variable model

and the 35 percent unexplained variability of the driver/road variable

plus tilt table angle model is 42 percent, which is 55 percent of the

unexplained variability in the driver/road variable model (42 percent/

77 percent). Slightly more than half of the variability unaccounted for

by driver and road characteristics was explained by the addition of

tilt table angle. Thus, the logistic regression analysis indicates that

stability, as measured by tilt table angle, is an important predictor

of the likelihood of a single vehicle accident becoming a rollover.

Substitution of critical sliding velocity produced similar results. A

complete discussion of the results of these analyses can be found in

the Addendum to Technical Assessment Paper in the docket.

Table 1.--Results of Logistic Regression Analysis for All Vehicles for

Which Tilt Table Angle (TTA) and Critical Sliding Velocity (CSV) Are

Known

------------------------------------------------------------------------

Percent

variability

Percent explained,

Model variability which is not

explained explained by D/

R/E only model

------------------------------------------------------------------------

D/R/E only.............................. 23 NA

D/R/E & TTA............................. 65 55

D/R/E & CSV............................. 75 68

------------------------------------------------------------------------

The linear regression analysis also demonstrates the predictive

power of tilt table angle and critical sliding velocity. This analysis

showed that tilt table angle accounts for about 53 percent of the

variability in rollover risk remaining after adjustment for differences

in driver and road characteristics. The analysis showed that critical

sliding velocity accounts for about 66 percent of the variability in

rollover risk remaining after adjustments for driver and road

characteristics. These compare to the 55 percent and 68 percent values

found by logistic regression. These figures demonstrate that the two

analytic methods are essentially in agreement regarding the statistical

significance of stability metrics to the prediction of rollover.

The results of both the logistic and linear regression analyses

performed by the agency suggest that a vehicle stability metric alone

can account for approximately 50 percent of the variability in rollover

risk in single vehicle accidents, for the population of make/models

studied. While ideally it would be desirable to have these variables

explain 100 percent of the remaining variability, such statistical

correlations are almost never achieved. The agency views these analyses

as demonstrating sound statistical and causal relationships between

these variables and the likelihood of rollover. At the same time, the

analyses show that other factors in addition to those analyzed are

affecting rollover risk, as 35 percent to 25 percent of the variability

in rollover risk is still unexplained after accounting for the driver,

roadway, and tilt table angle or critical sliding velocity,

respectively.

The above analyses used a Michigan accident data base combining

passenger cars, pickup trucks, vans, and sport utility vehicles. As

explained in section I, the rate of rollover fatalities and injuries

per million registered vehicles is higher for sport utility vehicles

and compact pickup trucks, but the absolute majority of harm occurs in

passenger cars, because of their large numbers in use. In the current

vehicle fleet, passenger cars generally have higher measured stability

than light trucks. Thus, a safety standard requiring a minimum level of

stability appropriate for all light duty vehicles would not be expected

to affect many present or future small cars and therefore would not

result in significant safety benefits. (For a further discussion of the

problems associated with a minimum standard, see the section below

entitled, ``Estimate of the Costs of a Standard.'')

Hence, the agency also examined the relative predictive capability

of the stability metrics to rollover risk for passenger cars and light

trucks separately, to investigate the possibility of setting a higher

minimum level of stability for passenger cars. The results are shown in

the table below, including a comparison to the results for all vehicles

considered as a single group (see Table 1). As with the analysis of all

vehicles considered as a single group, these analyses were limited to

make/models for which both tilt table angle and critical sliding

velocity were known.

Table 2.--Results of Logistic Regression Analysis for Vehicles by Class

----------------------------------------------------------------------------------------------------------------

TTA as metric CSV as metric

-----------------------------------------------------------------

Percent variability Percent variability

Vehicle class ---------------------- Percent ---------------------- Percent

D/R/E explain D/R/E explain

only + metric only + metric

----------------------------------------------------------------------------------------------------------------

All vehicle................................... 23 65 55 23 75 68

Lt. Truck only................................ 21 52 39 21 70 62

Car only...................................... 39 56 28 39 63 39

----------------------------------------------------------------------------------------------------------------

These results show that, while a good proportion of the variability

remaining in the driver/road/environmental model is explained by either

metric for the group containing all vehicles, when the vehicles are

divided into classes, the results are not consistent. The inconsistency

seen in the model results by vehicle class is, to some extent, the

result of the smaller range of the metric within any subgroup of

vehicles together with the inherent variability in the data. These

analyses and the analyses of benefits and costs discussed later,

indicate that different minimum standards for passenger cars and light

trucks cannot be supported using either tilt table angle or critical

sliding velocity.

VI. Decision Not To Propose a Vehicle Stability Standard

As discussed previously, NHTSA concluded that both of the vehicle

metrics, tilt table angle and critical sliding velocity, were

statistically and causally related to the likelihood of rollover in a

single vehicle crash. To determine whether to propose a vehicle

stability standard, NHTSA next compared the benefits and costs of such

a standard. A detailed discussion of the benefits analysis can be found

in ``Potential Reductions in Fatalities and Injuries in Single Vehicle

Rollover Crashes as a Result of a Minimum Rollover Stability

Standard,'' which has been placed in Docket No. 91-68, Notice 03. A

detailed discussion of the cost estimates can be found in the

Preliminary Regulatory Evaluation, which has also been placed in Docket

No. 91-68, Notice 03.

A. Estimate of the Benefits of a Standard

The agency made two basic estimates of benefits of a minimum

standard for rollover stability. One was based on the reductions in RO/

SVA predicted by the logistic regression model for increases in

critical sliding velocity. The other was based on reductions in RO/SVA

predicted for increases in tilt table angle. All other factors being

equal, it is reasonable to expect an inverse relationship between

rollover risk and either critical sliding velocity or tilt table angle.

Thus, the higher the lateral sliding velocity necessary to trip a

vehicle, the less likely it is to roll over, and vice versa. Similarly,

the greater the angle necessary to tip a vehicle from the tilt table,

the less likely it is to roll over, and vice versa.

To quantify the benefits of potential minimum standards for

rollover stability, NHTSA examined the net prevention of fatalities and

serious injuries associated with various minimum levels of critical

sliding velocity and tilt table angle. Fatality and injury levels were

estimated by using:

1. The reduction of the rollover risk predicted for increases in

critical sliding velocity or tilt table angle;

2. The number of single vehicle accidents per registered vehicle

expected to occur; and

3. The reduction in fatalities and/or injuries if a single vehicle

accident does not result in a rollover.

The estimate of the benefits of a minimum stability safety standard

incorporated several simplifying assumptions. First, the agency assumed

that the severity of the accidents would be reduced but that the

accidents would not be prevented. Because single vehicle rollover

accidents are more severe than single vehicle non-rollover accidents,

prevention of rollover reduces the number of serious injuries and

fatalities. However, under this scenario, the total number of single

vehicle accidents is assumed to remain constant. This assumption is

somewhat pessimistic, because an unknown number of crashes would most

likely be avoided. But the remaining assumptions used may tend to

overestimate the benefits since NHTSA also assumed:

1. The numbers of rollover injuries and fatalities prevented would

be proportional to the number of rollovers prevented, and

2. The fatality and injury rates of the late 1980s for the make/

models which would be affected by a minimum standard will remain

representative in the future.

The second assumption may overstate the benefits if increased

safety belt use in the 1990s, as is the goal of NHTSA, reduces the

overall harm from rollover accidents. That is, as belt use increases,

rollover casualties decrease, even though the number of rollover

crashes remains constant.

1. Rollover Risk Reduction

To estimate the reduction in the rollover risk that would be

obtained by changing a vehicle metric, the agency used logistic

regression to determine the sensitivity of rollover risk to changes in

critical sliding velocity or tilt table angle. The outcome of each

accident of the subject make/model in the data base was re-evaluated

individually changing the stability metric but retaining the other

vehicle, driver, and road characteristics present in the actual crash.

A new RO/SVA ratio was determined on the basis of the predicted outcome

of each accident.

To examine the sensitivity of the model to a change in critical

sliding velocity, the agency divided the range of critical sliding

velocities from 14.26 to 16.73 kilometers per hour (kph). The low end

of this range is representative of vehicles in NHTSA's database with

the lowest critical sliding velocity. The high end of this range is

representative of a critical sliding velocity equivalent to the 1.20

value for static stability factor recommended in the Wirth petition

(also equivalent to a tilt table angle of 46.4 degrees). (A discussion

of the Wirth petition can be found in the ANPRM, 57 FR 242, 244-45.)

The highest value in the range is greater than the proposed European

tilt table angle limit of 44.3 degrees, and in the agency's judgement

represents the highest practicable standard. A standard at the upper

limit of the range would affect 1,648,000 vehicles manufactured in

1991, including 87 percent of compact sport utility vehicles, 100

percent of standard vans, and 31 percent of compact pickups.

The agency then divided this range into six even increments and

calculated the RO/SVA for each increment for various classes of

vehicles. Each successively higher increment represents an increase in

critical sliding velocity of 0.41 kph. The agency then predicted the

decrease in single vehicle accident rollovers for each incremental

increase in critical sliding velocity. (See Table 3.)

Table 3.--Sensitivity of RO/SVA to Changes in CSV in kph Simulated by Logistic Regression Model for Vehicles of

CSV <16.73 kph

----------------------------------------------------------------------------------------------------------------

CSV range kph

Make/model --------------------------------------------------------------

14.26 14.68 15.09 15.50 15.91 16.32 16.73

----------------------------------------------------------------------------------------------------------------

Compact SUVs..................................... 0.434 0.420 0.406 0.391 0.378 0.364 0.350

Standard SUVs.................................... 0.347 0.334 0.320 0.307 0.294 0.282 0.269

Compact Pickup................................... 0.355 0.341 0.328 0.314 0.301 0.288 0.276

Minivan.......................................... 0.275 0.263 0.252 0.241 0.230 0.219 0.209

Standard Van..................................... 0.229 0.219 0.209 0.199 0.190 0.180 0.171

----------------------------------------------------------------------------------------------------------------

As an example, for vehicles with a critical sliding velocity

between 14.26 and 16.73 kph, an increase of 12 percent in critical

sliding velocity was predicted to decrease single vehicle accident

rollovers of compact sport utility vehicles by about 13 percent,

standard sport utility vehicles by about 15 percent, compact pickups by

about 15 percent, and minivans by about 16 percent. There is only one

standard van with a critical sliding velocity below 16.73 kph. Its

rollover risk is predicted to decrease 17 percent if its critical

sliding velocity were to increase 12 percent. A 12 percent increase in

critical sliding velocity represents a change of 1.65 kph, or four

increments. A complete discussion of these analyses can be found in the

paper ``Potential Reductions in Fatalities and Injuries in Single

Vehicle Crashes as a Result of a Minimum Stability Standard'' in the

docket.

A similar analysis was done using tilt table angle. For tilt table

angle, each increment was approximately equivalent to 0.75 degrees. For

vehicles with a tilt table angle between 42 and 46.4 degrees (the

equivalent of the critical sliding velocity range), an increase of 11

percent (also four increments, or 3.00 degrees) in tilt table angle was

predicted to decrease single vehicle accident rollovers among compact

sport utility vehicles by about 15 percent, standard sport utility

vehicles by about 19 percent, compact pickups by about 17 percent,

minivans by about 20 percent, and standard vans by about 22 percent.

(See Table 4.)

Table 4.--Sensitivity of RO/SVA to Changes in TTA Simulated by Logistic Regression Model for Vehicles of TTA

<46.4 deg.

----------------------------------------------------------------------------------------------------------------

TTA range

Make/model ----------------------------------------------------------------------------

42.0 deg. 42.8 deg. 43.5 deg. 44.3 deg. 45.0 deg. 45.7 deg. 46.4 deg.

----------------------------------------------------------------------------------------------------------------

Compact SUVs....................... 0.465 0.448 0.430 0.413 0.396 0.380 0.363

Standard SUVs...................... 0.293 0.278 0.264 0.249 0.236 0.223 0.210

Compact Pickup..................... 0.406 0.388 0.370 0.353 0.336 0.319 0.302

Standard Van....................... 0.178 0.168 0.158 0.148 0.139 0.130 0.122

Minivan............................ 0.265 0.251 0.238 0.225 0.212 0.200 0.189

----------------------------------------------------------------------------------------------------------------

2. Predicted Single Vehicle Accident Rate

To estimate the number of single vehicle accidents in a

hypothetical future vehicle population, NHTSA assumed that the future

population would have the same proportion of vans, pickups, and sport

utility vehicles as the 1991 production, and that the population would

have the same proportion of high and low critical sliding velocity and

tilt table angle vehicles within these categories.

NHTSA then distributed the numbers of serious injuries by vehicle

category (as tabulated by Data Link Inc., under contract to NHTSA)

among the 1991 example vehicles on the basis of relative production

volume, relative single vehicle accident involvement rate, and relative

rollover risk per single vehicle accident. (The Data Link reports are

available in Docket 91-68, Notice 2.) Data Link reported injuries and

fatalities by vehicle types: pickup truck, van, sport utility vehicle

(called MPV in Data Link reports), and car. NHTSA further divided the

vehicle types into subcategories of compact and standard to make

average accident rate and rollover risk more meaningful.

NHTSA also divided injuries and fatalities between compact and

standard versions of each vehicle type. To do this, NHTSA assumed that

rollover harm was proportional to the number of rollover accidents

within a vehicle type. The numbers of rollover accidents among compact

vehicles relative to those among their standard counterparts were

estimated by multiplying their 1991 production ratios by their single

vehicle accident per registered vehicle ratios and their RO/SVA ratios.

The total number of injuries and fatalities was then divided

proportionally.

The reduction in rollover harm for each type/size category is a

summary of the reductions in injuries and fatalities for each example

vehicle within the category if the tilt table angle for the category

were increased a specified level. The reduction in harm associated with

each affected vehicle is assumed to be proportional to its projected

reduction in rollover risk. A minimum tilt table angle standard of 42.8

degrees, an increase of one increment explained above, would be

expected to reduce serious rollover injuries by 13 and rollover

fatalities by 8. A minimum tilt table angle standard of 46.4 degrees,

the highest measurement in the range studied, would be expected to

reduce serious rollover injuries by 233 and rollover fatalities by 121,

if rollover avoidance were viewed as crash avoidance. A parallel

exercise was done using the rollover risk predicted using critical

sliding velocity as the stability metric in the logistic regression

model.

3. Injury/Fatality Rate Reduction

Because the agency assumed that a single vehicle accident would

still occur even though a rollover was prevented, it reduced these

estimates of benefits based on a comparison of the relative harm of

single vehicle accidents with rollover to that of similar accidents

without rollover. The comparison indicated that the overall fatality

rate for single vehicle rollover accidents was 2.07 times the fatality

rate for single vehicle accidents without rollover. When only accidents

occurring on roads with speed limits of 40-50 mph are considered, the

rollover accidents are 2.3 times as likely to result in fatality. When

accidents on 55-65 mph roads are considered, the fatality rate of

rollover accidents is 1.6 times that for other accidents. These

statistics suggest that rollover prevention is equivalent to about a 50

percent reduction in fatalities for the number of accidents in which

rollovers would be prevented.

Likewise, the injury data indicate an overall relative rate of

serious injuries (AIS 3+) 1.36 times greater for single vehicle

accidents with rollover than without rollover. The ratio of AIS 3+

injuries in non-rollover to AIS 3+ injuries in rollovers was 1.38 for

accidents occurring on roads with speed limits of 40-50 mph and 1.47

for accidents occurring on 55-65 mph roads. These statistics suggest

that rollover prevention is roughly equivalent to a 25 percent

reduction in serious injuries for the number of accidents in which

rollovers would be prevented.

Viewing rollover prevention as roughly a 50 percent mitigation of

fatalities and a 25 percent mitigation of serious injuries leads to an

estimate of net benefits resulting from the reduction in harm from

rollover accidents. Net reductions of 3 to 61 serious injuries and 4 to

63 fatalities would be expected for a minimum tilt table angle standard

in the range of 42.8 to 46.4 degrees. Net reductions of 3 to 68 serious

injuries and 2 to 68 fatalities would be expected for a minimum

critical sliding velocity standard in the range studied, i.e., 14.68 to

16.73 kph.

Minimum rollover stability requirements at the levels examined

would have minimal impact on the annual single vehicle accident

rollover fatality toll, because the vehicles affected would be less

than 20 percent of the total light duty vehicle fleet and the vehicles'

stability would only be improved by a marginal amount.

The great majority of rollover fatalities would be unaffected by a

minimum stability standard set at any of these levels, because they

occur in cars, which greatly outnumber light trucks in use, and which,

with few exceptions, have significantly higher rollover stability than

sport utility vehicles, pickup trucks, and vans.

B. Estimate of the Costs of a Standard

As explained above, the agency's analyses predicted a saving of 63

lives for a minimum tilt table angle of 46.4 degrees. This level would

necessitate the modification of an estimated 87 percent of present

compact sport utility vehicles and virtually all present standard vans.

A minimum tilt table angle of 45 degrees, which is higher than the tilt

table angle of 69 percent of present compact sport utility vehicles,

could save 23 lives. Similarly, a minimum critical sliding velocity

standard of 16.73 kph would affect 89 percent of present compact sport

utility vehicles, 38 percent of standard sport utility vehicles, and 38

percent of compact pickups, while saving 68 lives. A critical sliding

velocity minimum standard of 15.91 kph would affect 71 percent of

compact sport utility vehicles and 31 percent of compact pickups, while

saving 34 lives.

Unfortunately, inexpensive vehicle changes, such as offset wheels

or modified tire and rim width combinations, cannot be counted on to

improve stability without producing handling or steering problems. An

increase in track width, derived from frame or suspension alterations,

or a decrease in center of gravity height are the only methods of

improving stability without potential safety liabilities. Such changes

would require large initial costs related to the design and development

of major vehicle components, if not the entire vehicle.

These costs do not take into account the cost of the tests

necessary to determine the tilt table angle or critical sliding

velocity. Because these costs will also be associated with the proposed

consumer information regulation, the testing costs are discussed later

in this notice.

Some of the changes necessary to comply with a minimum standard may

also be incompatible with some of the vehicle characteristics many

consumers seek in vehicles such as sport utility vehicles, vans, motor

homes, and campers. For example, in the case of sport utility vehicles,

the capability to operate in off-road conditions may require both high

ground clearance (necessitating a relatively high center of gravity)

and narrow width to maneuver in wooded or rocky areas (necessitating a

relatively narrow track width). Section 103(f)(3) of the National

Traffic and Motor Vehicle Safety Act provides that a Federal motor

vehicle safety standard must be reasonable and appropriate for each

vehicle type to which it applies, and therefore NHTSA could not mandate

a stability requirement incompatible with certain types of vehicles. In

addition, the manufacturers of many of these types of vehicles would be

considered small businesses, and a standard could raise concerns under

the Regulatory Flexibility Act.

Another possible cost of a minimum rollover standard is decreased

fuel economy. Compact sport utility vehicles have become popular, in

part, because the original sport utility vehicles, which were larger,

heavier, and more stable against rollover, were also more difficult to

park and maneuver and had very poor fuel mileage. The compact sport

utility vehicles with higher stability tend to be the larger vehicles

in the class, or open vehicles with less mass in the top. A stability

standard would be expected to cause a growth in size and weight of

compact sport utility vehicles and a reduction in fuel mileage.

C. Conclusions

Based on these estimates of the benefits and costs of a minimum

stability standard, NHTSA believes that the benefits would not be

sufficient to justify the expected costs. Therefore, as noted above,

NHTSA has decided to defer any further action on this subject until

information becomes available demonstrating the cost effectiveness of

such a rule. The agency may reinitiate such a rulemaking upon receipt

of such information. This termination of rulemaking on vehicle

stability fulfills the statutory mandate of Section 2502(b)(2)(B)(i).

While the agency is terminating rulemaking on a vehicle stability

standard, NHTSA believes that the correlation between stability and

rollover risk is significant enough to justify proposing a consumer

information regulation to relieve the possibility of uninformed risk.

The agency's decision to propose such a regulation is explained below.

VII. Proposed Consumer Information Regulation

A. Rationale

NHTSA is proposing a new consumer information regulation requiring

manufacturers to report the stability metric of cars and light trucks

to enable consumers to make more informed choices concerning the trade-

offs of vehicle attributes and rollover stability. NHTSA believes that

a consumer information regulation would inform drivers of general

differences in stability between light trucks and cars, and among

vehicles in those classes so that consumers can make an informed choice

concerning relative rollover risk. This regulation would inform drivers

who still chose a less stable vehicle that they may wish to drive more

cautiously in certain circumstances and that the higher risk of driving

low stability vehicles can be greatly reduced by using safety belts. In

addition, NHTSA believes that a consumer information regulation would

motivate manufacturers to give more priority to rollover stability in

the design of new vehicles. NHTSA believes these goals can be

accomplished with a minimum burden on industry and consumers.

NHTSA believes that consumer and manufacturer behavior can be

affected through the provision of consumer information. The agency's

experience with the New Car Assessment Program (NCAP) demonstrates the

power of consumer information. Several manufacturers have informed the

agency that they have internal goals of performing well in these 35 mph

frontal crash tests, even though there is no regulatory requirement to

do so. The lowering of the injury scores over time for all

manufacturers, as reported in ``Report on the Historical Performance of

Different Auto Manufacturers in the New Car Assessment Program Tests'',

NHTSA, August 1993, can also be attributed partially to NCAP. The

attention of the media to the program and the more than 20,000 calls

annually to NHTSA's Hotline, the most for any NHTSA consumer

information activity, speak to the consumer's interest in relevant

consumer safety information. As to whether consumers want information

on rollover, recent agency focus groups indicate they would (``Focus

Groups on Traffic Safety Issues: Public Response to NCAP,'' S.W. Morris

& Company, Inc., August 1993, which can be found in Docket No. 79-17,

Notice 01). The consensus of the focus groups was that the agency's

consumer safety information activities should be expanded to include

additional kinds of crashes, including rollover. Consumers also desired

point of sale information, which would be satisfied with the proposed

vehicle sticker requirement.

NHTSA does not agree with those manufacturers who believe that

labeling vehicles with stability information will mislead consumers or

that consumers would consider the metric an absolute measure of the

likelihood of rollover, regardless of driver behavior or roadway

conditions. It has never been shown that improvements in safety or

availability of information regarding safety increase risk-taking. In

addition, the proposed label not only contains the stability

information, it contains the statements: ``All vehicles roll over!

Always wear seat belts! In a rollover crash, an unbelted person is 6 to

9 times more likely to die than a person wearing a seat belt.'' These

statements emphasize to the consumer that a vehicle with a higher

stability rating can still roll over.

NHTSA is considering two possible options for specifying the

stability metric. Under option one, NHTSA would select one of two

metrics, critical sliding velocity or tilt table angle, and require the

metric to be stated for each vehicle. NHTSA requests comments on which

metric is preferable if NHTSA selects only one metric. (Note: The

proposed regulatory text in this notice illustrates this option first

for critical sliding velocity, and then for tilt table angle.) Under

option two, NHTSA would not require a metric to be stated. Instead, the

agency would require vehicles to be labeled with a statement concerning

the rollover stability (e.g., one, two, or three stars) based on

vehicle performance when tested for one or both of the metrics.

B. Proposed Label

NHTSA is proposing to require three types of information on the

label and in owner's manuals. First, manufacturers would be required to

include the stability metric for that vehicle. This information would

either be the same as that reported by the manufacturer to NHTSA (for

option one) or the ``rating'' provided by NHTSA (for option two). This

metric would be required to be reported ``accurate to the nearest

kilometer per hour'' for critical sliding velocity and ``accurate to

the nearest degree'' for tilt table angle. As explained in the

discussion of the two metrics in this notice, NHTSA believes that the

test procedure for both metrics produces results repeatable to this

degree of accuracy. Manufacturers would be allowed to choose which

models and configurations could be grouped together, because they have

the same metric, for the purpose of reporting metrics. However, for

each metric reported by a manufacturer, the manufacturer would have to

fully describe the vehicles to which the metric applies.

Second, the label would be required to contain the metric or rating

ranges provided by NHTSA for both passenger cars and light trucks. The

purpose of this requirement is to emphasize to consumers that there are

significant differences between the stability of the average passenger

car and that of the average truck-based vehicle. This information would

allow consumers to make an informed choice in purchasing a passenger

car or a truck-based vehicle and to compare a vehicle they are

considering to other vehicles in its class.

Third, NHTSA is proposing to require a warning to inform consumers

that all vehicles can, and do, roll over and that the best protection

against injury or fatality, should a rollover occur, is wearing seat

belts.

C. Stability Metrics

As noted above, NHTSA's analyses indicate that there are two

metrics, critical sliding velocity and tilt table angle, which

correlate well with rollover accident data. Either of these metrics

could be used in a stability labeling regulation. Each has its

advantages and disadvantages.

Critical sliding velocity, a dynamic metric, includes the influence

of roll moment of inertia as well as the various static factors

included by the static metrics such as tilt table angle. The advantage

of critical sliding velocity is that it more consistently predicts

rollover risk for light trucks. The disadvantage is that calculation of

critical sliding velocity requires knowledge of the vehicle's center of

gravity height and roll mass moment of inertia. These two parameters

are difficult to measure on complete vehicles and require specialized

equipment to obtain accurate results. However, these parameters can be

measured on vehicle components and manufacturers of complete vehicles

could calculate center of gravity height and roll mass moment of

inertia of complete vehicles from data they have on component

parameters. However, the agency is unsure whether final stage

manufacturers and alterers of specialty vehicles are provided enough

information from incomplete vehicle manufacturers to do this.

Tilt table angle, a static metric, is simple and inexpensive to

measure. The nature of the test is easy for the consumer to understand.

The disadvantage of this metric stems from the statistical relationship

between tilt table angle and accident data. The correlation between

tilt table angle and accident data breaks down if passenger cars are

analyzed separately from light trucks. Further, statistical models

containing tilt table angle data consistently overestimate the rollover

risk for standard vans.

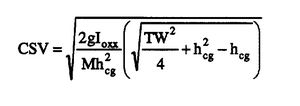

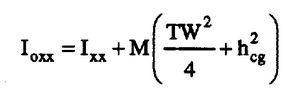

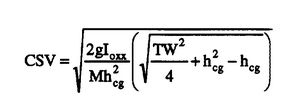

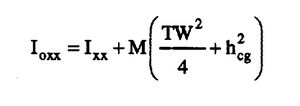

1. Critical Sliding Velocity

Critical sliding velocity, in kilometers per hour, is determined

from the equation:

where,

where,

and

I

and

Ixx = roll mass moment of inertia of the vehicle, in kilogram-

kilometers\2\

g = gravitational constant, in kilometers/hour\2\

M = mass of the vehicle, loaded, in kilograms

hcg = center of gravity height of the vehicle, in kilometers

TW = the average of the front and rear track width of the vehicle, in

kilometers.

Calculation of critical sliding velocity requires knowledge of the

vehicle's mass, track width, center of gravity height, and roll moment

of inertia. NHTSA agrees with commenters that the center of gravity

height and roll moment of inertia are complicated measurements. To

address comments on the repeatability of center of gravity height

measurement, NHTSA reviewed two reports.

The study ``Center of Gravity Height: A Round-Robin Measurement

Program,'' sponsored by the Motor Vehicle Manufacturers Association and

conducted by the University of Michigan Transportation Research

Institute (UMTRI-91-4) compared the test facilities, procedures, and

results of center of gravity height measurements at four laboratories.

Each of the four laboratories used different test equipment and

procedures. The study concluded that different measurement procedures

can produce significantly different results. However, the study also

concluded that for each laboratory and test procedure, repeatability

was very good.

Another study, ``Vehicle Inertial Parameters--Measured Values and

Approximations,'' by Garrott et al. (Society of Automotive Engineers

#881767) shows the coefficient of variation of center of gravity height