Federal Motor Vehicle Safety Standards; Child Restraint Systems |

|---|

Topics: National Highway Traffic Safety Administration

Topics: National Highway Traffic Safety Administration

|

Barry Felrice

Federal Register

March 16, 1994

[Federal Register: March 16, 1994]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 74-09; Notice 35]

RIN 2127-AF02

Federal Motor Vehicle Safety Standards; Child Restraint Systems

AGENCY: National Highway Traffic Safety Administration (NHTSA),

Department of Transportation.

ACTION: Notice of proposed rulemaking (NPRM).

-----------------------------------------------------------------------

SUMMARY: This document addresses the possible need to add a greater

array of test dummies to Standard 213 for use in compliance tests. It

is the second of two proposals on child booster seat safety resulting

from the Intermodal Surface Transportation Efficiency Act of 1991. That

Act directed NHTSA to initiate rulemaking on child booster seat safety.

The first NPRM proposed to amend Standard 213's requirements for child

booster seats designed for use with a vehicle's lap and shoulder belts.

Today's NPRM is intended to improve the safety of booster seats and

other types of child restraint systems by providing for their more

thorough compliance testing.

DATES: Comments on this document must be received by the agency no

later than May 16, 1994. The proposed effective date is 180 days after

the date of publication of a final rule.

ADDRESSES: Comments should refer to the docket number and notice number

and be submitted in writing to: Docket Section, National Highway

Traffic Safety Administration, room 5109, 400 Seventh Street, SW.,

Washington, DC, 20590. Telephone: (202) 366-5267. Docket hours are 9:30

a.m. to 4 p.m. Monday through Friday.

FOR FURTHER INFORMATION CONTACT:

Dr. George Mouchahoir, Office of Vehicle Safety Standards, National

Highway Traffic Safety Administration, 400 Seventh St., SW.,

Washington, DC, 20590 (telephone 202-366-4919).

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Introduction.

a. Purpose of this NPRM.

b. Previous NPRM.

II. Specific proposals.

a. Child dummies.

1. Dummy selection based on recommended weight of child

restraint users.

2. Dummy selection based on recommended sitting height of child

restraint users.

b. Performance criteria.

c. Clarifying amendments.

d. Other issues.

III. Rulemaking Analyses and Notices.

a. Executive Order 12866 and DOT Regulatory Policies and

Procedures.

b. Regulatory Flexibility Act.

c. Executive Order 12612.

d. National Environmental Policy Act.

e. Executive Order 12778.

IV. Comments on the proposal.

I. Introduction

This document follows an advance notice of proposed rulemaking

(ANPRM) published on May 29, 1992 about child booster seat safety (57

FR 22682). The ANPRM was issued in response to the National Highway

Traffic Safety Administration Authorization Act of 1991 (sections 2500-

2509 of the Intermodal Surface Transportation Efficiency Act

(``ISTEA'')). That Act directed the agency to initiate rulemaking on

child booster seat safety and other issues.

The legislative history of the ISTEA directive on booster seats

sheds light on the source of Congress's concerns about booster seats.

That history, and Congress's concerns, were discussed in detail in the

May 1992 ANPRM, and are briefly summarized below.

The ISTEA directive originated in S. 1012, a bill reported by the

Senate Committee on Commerce, Science, and Transportation and added

verbatim to the Senate's surface transportation bill (S. 1204). The

Senate Commerce Committee report on S. 1012 expressed concern about

suggestions that booster seats, ``depending on their design, can be

easily misused or are otherwise harmful,'' and that some child seat

boosters ``may not restrain adequately a child in a crash.''

The committee's concerns about the possible inability of a booster

seat to restrain some children adequately stemmed from a study\1\

performed by Calspan Corporation. Calspan found that when the then-

manufactured booster seats were tested with test dummies representing

the range of children for whom the seats were recommended, the booster

seats did not appear to be able to adequately restrain all of those

test dummies. When tested to the requirements of Standard 213, however,

the booster seat passed the requirements because the standard specifies

the use of only one dummy, a dummy representing a 3-year-old (33 pound)

child, for testing a booster seat. (See S7.2 of Standard 213.) The

implication of these test results was that test dummies representative

of a wide range of child sizes were needed in Standard 213 to more

effectively test the performance of booster seats and other child

restraint systems. What seemed especially needed was an array of

dummies representing children at or near the extremes of the weight

ranges identified by a manufacturer as being suitable for any type of

child restraint.

---------------------------------------------------------------------------

\1\``Evaluation of the Performance of Child Restraint Systems''

(DOT HS 807 297, May 1988).

---------------------------------------------------------------------------

a. Purpose of Today's NPRM

This document proposes to add additional sizes of child compliance

test dummies to Standard 213, consistent with ISTEA's mandate and the

potential safety problems shown in the Calspan study. NHTSA's efforts

to address those safety problems, including the possibility of new test

dummies, were begun prior to ISTEA. Amending Standard 213 to

incorporate additional test dummies for use in compliance tests has

been one of NHTSA's main initiatives for upgrading Standard 213, as

stated in NHTSA's ``Planning Document on the Potential Standard 213

Upgrade,'' July 1991 (docket 74-09-N21). To that end, NHTSA developed

specifications for three new test dummies and completed rulemaking in

1991 and 1993 incorporating those specifications into part 572, the

agency's regulation on anthropomorphic test dummies. This step

facilitated the use of those dummies in the development of improved

child restraints.

Today's document, together with a companion NPRM published on

September 1, 1993 (discussed in the next section), responds to ISTEA as

well as follows up on the agency's 1991 planning document regarding

possible ways of upgrading Standard 213. As explained in the ``Other

Issues'' section of this document, some of the ways of upgrading

Standard 213 will be addressed over the course of several rulemakings.

As to the other ways, some are being further evaluated; the remaining

ones do not appear viable candidates for rulemaking. The agency notes

that, in accordance with its plan to convert to the metric system

pursuant to the Omnibus Trade and Competiveness Act and E.O. 12770,

today's proposal uses metric units. Thus, English units that are in

sections of Standard 213 affected by this NPRM would be converted to

metric units. For example, ``nine kilograms (kg)'' would replace

references in the standard to ``20 pounds.''

b. Previous NPRM

The companion NPRM to this document was published on September 3,

1993 (58 FR 46928). The NPRM, which also resulted from the May 1992

ANPRM, proposed to amend Standard 213 to permit the manufacturer and

sale of belt-positioning booster child seats (child seat boosters

designed for use with a vehicle's lap/shoulder belt system). NHTSA said

it believes that facilitating the manufacture of belt-positioning

booster seat could improve booster seat safety because belt-positioning

seats appear to be capable of accommodating a wider range of child

sizes than currently manufactured shield-type boosters. Also, NHTSA

stated that it believes there is a possibility that belt-positioning

booster seats used with vehicle lap/shoulder belts would perform better

than shield booster seats. NHTSA proposed amending Standard 213's

compliance test procedures to specify that belt-positioning booster

seats would be dynamically tested when restrained to the test apparatus

with a lap/shoulder belt. NHTSA also proposed labeling and

informational requirements to decrease the possibility that booster

seats would be misused.

II. Specific Proposals in Today's NPRM

a. Child Dummies

Three new child dummies have been tentatively selected to be added

to Standard 213 for use in the compliance testing of child

restraints.These dummies are the newborn infant dummy described in

subpart K of 49 CFR part 572, the 9-month-old dummy in subpart J, and

the instrumented 6-year-old dummy in subpart I. The biofidelity,

reliability and repeatability of the test dummies were discussed in the

documents incorporating the dummies into part 572 for the purpose of

facilitating child restraint development. See, final rule for newborn

dummy (January 8, 1993, 58 FR 3229); 9-month-old dummy (August 19,

1991; 56 FR 41077); 6-year-old dummy (November 14, 1991; 56 FR 57830).

This document proposes detailed descriptions of the clothing,

conditioning and positioning procedures for the dummies to ensure that

the test conditions are carefully controlled. The clothing that would

be specified is the same, except for size, as that used for the 3-year-

old dummy. The conditioning specifications are the same as those

currently used for the 3-year-old dummy.

With the addition of the three new dummies, there would be four

child test dummies used for Standard 213 compliance testing. The fourth

dummy would be the existing 3-year-old dummy (subpart C) for Standard

213 testing. As to the other existing dummy, the 6-month-old, 17 pound

(8 kg) dummy (subpart D), the agency has tentatively decided that it

would no longer use that dummy to test child restraints. The agency has

tentatively decided that testing child restraints with that dummy is

unnecessary since the newborn and 9-month-old dummies appear sufficient

to evaluate the performance of a child restraint recommended for

infants. Comments are requested on whether the 6-month-old, subpart D

dummy would still be needed to test child restraints, and if so, which

restraints should be tested with that dummy.

In its comment on the ANPRM, General Motors (GM) expressed concern

about the 6-year-old and the 3-year-old dummies. GM asked NHTSA to

refer to GM's comments on the agency's earlier rulemaking proposals to

incorporate these dummies in part 572 to aid in child restraint

development. According to GM, those comments ``detail (GM's) concerns

regarding limitations of these test devices * * * .'' While the comment

is unclear as to what GM means by ``limitations,'' NHTSA assumes the

commenter is referring to the biofidelity and suitability of the

dummies as test devices, or the ability of the dummies to measure

various crash forces imposed on them. NHTSA responded to issues about

the biofidelity and suitability of the dummies in the previous

rulemakings on part 572. The agency is not aware of any information,

submitted by GM or arising elsewhere, indicating that these dummies

have ``limitations'' warranting their exclusion from use in Standard

213 testing. Moreover, information on the performance of the dummies in

tests conducted subsequent to their incorporation into part 572 does

not indicate any problems with their performance. Recently, these

dummies were used along with the part 572 three-year-old in a large

number of sled tests that NHTSA conducted as part of its child safety

research program that was described in the agency's 1991 planning

document to upgrade Standard 213. These dummies appeared to perform

satisfactorily, without any problem that would prevent their

incorporation into FMVSS 213. The findings of this research program

were summarized in a series of reports that were published in October

1992, under project VRTC-82-0236 ``Child Restraint Testing (Rulemaking

Support).'' These reports are available from the National Technical

Information Service, Springfield, Virginia, 22161.

GM suggested in its ANPRM comments that the child test dummies

should provide a ``more complete set of measurements'' than currently

provided by the three-year-old dummy. GM suggested including the

additional measurement of forces imposed on the dummy's neck, abdomen,

and femur areas. GM stated that injuries to children's neck, abdomen,

and hip, thigh and knee areas can be serious, and that performance

criteria for these injuries should be developed. GM said that these

criteria can be measured and the neck and femur load cells are

currently available for most child dummies. The commenter also said

that the development of a device to measure abdominal injury is both

possible and essential.

NHTSA responded to an identical comment from GM on this issue in

the rulemaking adopting the 6-year-old dummy specifications into part

572. The part 572 6-year-old dummy, referred to as SA106C, can provide

measurements of crash forces imposed on the dummy's femurs, in addition

to measurements of head and chest accelerations. In the rulemaking

adopting the SA106C dummy (the same dummy being considered today) into

part 572, GM suggested that NHTSA adopt a 6-year-old dummy based on the

50th percentile male Hybrid-III dummy instead of the SA106C 6-year-old

dummy, because the Hybrid-III child dummy was superior in its

instrumentation.

NHTSA responded: Ford and GM might be correct that the Hybrid-III

type 6-year-old dummy (which has yet to be completed and evaluated)

might eventually have potential advantages over the NHTSA/Humanoid

dummy in the number of parameters the dummies can measure. However,

NHTSA does not believe that this rulemaking should be delayed to

further consider the potential advantages of future dummies. The SA106C

dummy's ability to measure HIC, chest acceleration and femur loads, and

its ability to replicate the motions and excursions of a child in a

crash are sufficient to provide valid assessment of the injury

potential of child restraint systems in a reliable manner. Since the

SA106C dummy is ready now, and a final rule specifying the dummy will

help improve safety, the agency believes it is appropriate to proceed

with adding the dummy to part 572. NHTSA intends to evaluate the

Hybrid-III type 6-year-old dummy after the dummy's design and

development are completed and the dummy is commercially available.

NHTSA is not aware of any information showing that an alternate

child test dummy, such as the Hybrid-III 6-year-old dummy, instead of

the part 572 dummy, should be incorporated into Standard 213.

Accordingly, NHTSA has decided to proceed with this proposal to

incorporate the part 572 6-year-old dummy.

1. Dummy Selection Based on Recommended Weight of Restraint Users

NHTSA proposes amending the provisions is S7 of Standard 213 that

specify the child dummy or dummies to be used in testing a particular

child restraint system. Currently, S7 specifies that the 6-month-old

dummy is used for testing a child restraint system that is recommended

by its manufacturer for children weighing up to 20 pounds, and the 3-

year-old dummy is used for testing a child restraint that is

recommended for children weighing more than 20 pounds. If a child

restraint system is recommended for use by children in a weight range

that includes some children below 20 pounds and others above 20 pounds,

the both dummies are to be used.

The ANPRM discussed how the agency might determine which new test

dummies might be used under Standard 213 in the compliance testing of a

particular child restraint system: S7.2 of the standard could be

amended in the following manner. A restraint that is recommended for

use by children in a weight range that includes children weighing not

more than 7.5 pounds would be tested with the newborn dummy; from 7.5

to 20 pounds, with both the newborn and the nine-month-old dummy; from

20 to 33 pounds, with both the nine-month-old and three-year-old dummy;

from 33 to 40 pounds, with the three-year-old dummy; and 40 pounds and

above, with the six-year-old dummy. The agency anticipates proposing

these, or similar, weight ranges in the near future.

The commenters generally supported using the newborn, 9-month-old,

3-year-old and 6-year-old dummies for Standard 213 compliance testing.

Gerry, Cosco, Century Products and New York State supported using the

3-year-old and 6-year-old dummies to test booster seats recommended for

children weighing more than 35 pounds.

However, commenters also had suggestions for revising the weight

ranges discussed in the ANPRM. Advocates believed that the weight

ranges were deficient because only two of the ranges (7.5 to 20 pounds

and 20 to 33 pounds) would have two test dummies, one for the lower

weight limit and another for the upper weight limit. SafetyBeltSafe

believed the 3-year-old (33 pound) dummy should be used to test booster

seats recommended for children weighing more than 40 pounds, to address

the possibility that parents might ``rush'' a child into a booster seat

when a second child needs to use the toddler restraint. Cosco believed

that any child seat recommended for children weighing over 40 pounds

should be tested with both the 3-year-old and the 6-year-old dummies,

so that dummies at the extreme weight ranges are used.

NHTSA generally agrees with these comments. The agency proposes to

amend the weight specifications in S7 of Standard 213 so that to the

extent possible, each child restraint system would be subject to being

tested using at least two test dummies. To ensure that all children

recommended for a restraint are adequately restrained, the dummies used

to test a restraint would represent a wide range of child sizes.

However, NHTSA has not proposed to combine the 20 to 33 pound and

the 33 to 40 pound ranges into a 20 to 40 pound range, as Cosco

suggested. Cosco stated that it believes that the weight ranges should

be combined so that child restraints in the 20 to 40 pound range are

tested with the 9-month-old and 3-year-old dummies. NHTSA has

tentatively determined that booster seats (typically recommended for

children 30 pounds and above) need not be tested with the 9-month-old

(20 pound) dummy. This is because the September 1993 NPRM on child

booster seat safety included a proposal that booster seats must be

labeled for children weighing not less than 30 pounds. If that proposal

is adopted, the label would likely reduce the chances that a booster

seat would be used with children weighing in the 20 pound range.

Comments are requested on this issue.

NHTSA proposes the following provisions for determining which dummy

or dummies are to be used for testing child restraints, based on child

mass:

A child restraint that is recommended by its manufacturer

for children in a specified weight range that includes any children

having a mass less than 4 kilograms (i.e., 9 pounds or less) is tested

with a newborn test dummy conforming to part 572 subpart K.

A child restraint that is recommended for children in a

specified weight range that includes any children having masses from 4

to not more than 9 kilograms (weights of 9 to 20 pounds) is tested with

a newborn test dummy and a 9-month-old test dummy conforming to part

572 subpart J.

A child restraint that is recommended for children in a

specified weight range that includes any children having masses from 9

to not more than 13.5 kilograms (weights of 20 to 30 pounds) is tested

with a 9-month-old test dummy and a 3-year-old test dummy conforming to

part 572 subpart C.

A child restraint that is recommended for children in a

specified weight range that includes any children having masses equal

to or greater than 13.5 kilograms (30 pounds and above) is tested with

a 3-year-old test dummy and a 6-year-old test dummy conforming to part

572 subpart I.

If a child restraint is recommended for a weight range of children

that overlaps, in whole or in part, two or more of the weight ranges

set out above, the restraint would be tested with the dummies specified

for each of those ranges. Thus, for example, if a child restraint were

recommended for children having masses greater than 13 kilograms, it

would be tested with the 9-month-old dummy, the 3-year-old dummy and

the 6-year-old dummy.

2. Dummy Selection Based on Recommended Sitting Height of Restraint

Users

The fundamental purpose of today's proposal is to ensure that each

child restraint performs as intended in restraining the range of

children recommended for it. Thus, in addition to the above

specifications for selecting test dummies based on recommended weight

ranges, the agency proposes to supplement those specifications with

provisions for selecting test dummies based on recommended sitting

height ranges. More specifically, NHTSA would establish supplementary

provisions specifying the use of a particular test dummy based on the

child restraint manufacturer's recommendations regarding the sitting

height of the children for whom the restraint is intended. The effect

of those provisions might in some cases be to increase the number and

variety of dummies with which a child restraint would otherwise have

been tested based solely on the manufacturer's recommendations

regarding the weight of children for whom it's restraint is suitable.

Since the Standard currently requires manufacturers to provide

recommendations concerning (standing) height, this document proposes to

change the Standard to require recommendations regarding sitting height

instead of standing height. The sitting height of a seated child is

measured from the seating surface to the top of the child's head.

Comments are requested on the merits of using a sitting height

criterion.

This issue relating to the height of the restrained child was

addressed by some commenters. Advocates commented that ``. . . child

restraints must be compliance tested for specific ranges of child

occupant sizes that appropriately match the restraint use

recommendations to the size, weight, and height, of the intended child

occupants.'' Cosco stated that as children get older, it is the height,

instead of the weight, that becomes more of a determining factor in

correct car seat use.

The agency tentatively agrees that a manufacturer's recommendations

about the suitability of the restraint for children of a particular

height should be a factor in determining the size of the dummy or

dummies to be used to test the restraint. NHTSA is concerned that if

height were not a factor, it might be possible for a restraint to be

tested with a dummy or dummies insufficiently representative of the

range of children recommended for the restraint. This could occur if a

manufacturer were to recommend inconsistent mass and height ranges. A

manufacturer could create an inconsistency by recommending a height

range that corresponds to children who are of greater mass (weight)

than the masses expressly recommended by the manufacturer for the

restraint.

For instance, suppose an infant restraint were recommended for

children with masses not more than 4 kilograms (approximately 9 pounds)

and a sitting height of up to 475 mm. Although the use of both the

newborn and 9-month-old dummies would be more representative of the

users of the restraint, only the newborn dummy would be used if dummy

selection were based solely on the mass recommendation. However,

according to a report by the University of Michigan on ``Physical

Characteristics of Children as Related to Death and Injury for Consumer

Product Safety Design,'' Report No. PB-242-221, of children with masses

of 4 kilograms, those in the 95th percentile have a sitting height of

approximately 450 mm. Since the restraint is recommended for children

with heights greater than the 95th percentile child, NHTSA has

tentatively determined that it would be appropriate to test the infant

restraint not only with the infant dummy, but also with a test dummy

representative of a taller child (i.e., with the 9-month-old dummy).

NHTSA proposes the following provisions for determining which dummy

or dummies to use for testing child restraints, based on child sitting

height.

A child restraint that is recommended for children in a

specified sitting height range that includes any children whose sitting

height is not more than 450 mm (450 mm is approximately the sitting

height for a 95th percentile newborn male child), is tested with a

newborn test dummy conforming to part 572, subpart K.

A child restraint that is recommended for children in a

specified sitting height range that includes any children whose sitting

height is between 451 mm and 500 mm (500 mm is approximately the

sitting height for a 95th percentile nine-month-old male child whose

mass is 9 kilograms), is tested with a newborn test dummy and a 9-

month-old test dummy conforming to part 572, subpart J.

A child restraint that is recommended for children in a

specified sitting height range that includes any children whose sitting

height is between 501 mm and 600 mm (600 mm is approximately the

sitting height for a 95th percentile three-year-old male child whose

mass is 13.5 kilograms), is tested with a 9-month-old test dummy and a

3-year-old test dummy conforming to part 572, subpart C.

A child restraint that is recommended for children in a

specified sitting height range that includes any children whose sitting

height is equal to or greater than 600 mm is tested with a 3-year-old

test dummy and a 6-year-old test dummy conforming to part 572, subpart

I.

If a child restraint is recommended for a sitting height range of

children that overlaps, in whole or in part, two or more of the height

ranges set out above, the restraint would be tested with the dummies

specified for each of those ranges. Thus, for example, if a child

restraint were recommended for children having sitting heights greater

than 480 mm, it would be tested with the 9-month-old dummy, the 3-year-

old dummy and the 6-year-old dummy.

b. Performance Criteria

The performance criteria which a child restraint must meet when

restraining a dummy would generally be unchanged, except as described

later in this section. Thus, the requirements regarding dynamic

performance (including the head and chest injury criteria and

excursion), force distribution, installation, child restraint belts and

buckles and flammability would generally be uniform for all restraints,

regardless of the size of the dummy used. For example, Standard 213

currently requires a child restraint to limit forces on the head and

chest of the 3-year-old test dummy, to 1000 HIC (head) and 60 g's

(chest). These criteria would be unchanged for testing done with the 6-

year-old dummy.

GM commented on the general appropriateness of the existing injury

criteria for children. The HIC and chest g's injury criteria are the

same as those specified in Standard 208, Occupant Crash Protection (49

CFR 571.208) for motor vehicles when they are tested with the 50th

percentile adult male dummy. GM stated that it believes the values for

the child dummies should be separately scaled from the adult dummy ``to

reflect anatomical differences and differing injury tolerance of

children.''

NHTSA does not agree. As to specifying different HIC values for

each child dummy, the agency does not believe that a consensus exists

on values for such limits. No person commenting on the agency's

rulemaking proposals for child restraint systems, or otherwise

providing information to the agency, has been able to provide actual

data on head injury of children of various ages to support any

suggested value for HIC other than 1000 HIC. Moreover, comments on

NHTSA's planning document agreed that the limits of 1000 HIC and 60g

chest are acceptable for the three- and six-year-old dummies. The

commenters believed that those limits are not appropriate for smaller

sized dummies, which is an issue not addressed by this NPRM. Based on

this information, NHTSA is proposing to use the 1000 HIC and 60g chest

acceleration limits of Standard 213 for the six-year-old dummy.

Some requirements in Standard 213 would differ depending on the

child test dummy used. As noted above, a child restraint might be

tested with multiple dummies under this proposal. In that event, the

largest of the dummies used in the testing would also be used for

determining the applicability of the seat back requirement and for

determining compliance with that requirement.

However, the 6-year-old dummy would not be used to determine either

whether a seat back is needed on a child restraint or whether a

required seat back is high enough although that restraint had been

tested for compliance with the dynamic performance requirements using a

6-year-old dummy. Standard 213 currently requires certain child seats

to have a seat back to provide restraint against rearward movement of

the child's head (rearward in relation to the child). (S5.2.1) The

determination of whether a seat back is required on a child restraint

is based on the dummy used in the compliance testing of the restraint.

A child restraint need not have a seat back if a specified point on the

dummy's head (approximately located at the top of the dummy's ears) is

below the top of the standard seat assembly to which the restraint is

attached for compliance testing. (S5.2.1.2) Booster seats are currently

tested with the 3-year-old dummy, which sits low enough on the standard

seat assembly that the point on the dummy's head is not above the top

of the seat assembly. Since that dummy is used, booster seats need not

have seat backs. If the 6-year-old dummy were to be incorporated into

Standard 213 and if S5.2.1 were to remain unchanged, the impact on

booster seats could be substantial. Most, if not all, booster seats

(and perhaps other types of child seats) might have to be redesigned to

have a seat back. This is because the sitting height of the 6-year-old

dummy is higher than that of the 3-year-old. As a result, the critical

point on the head of the 6-year-old dummy is likely to be above the top

of the seat assembly. There may be additional costs associated with

such redesign.

NHTSA does not know of real world crash data that indicate a

problem with head or neck injuries in rear impact crashes. (See also,

denial of petition for rulemaking to require a special warning on child

seats addressing possible whiplash injuries due to lack of head

restraint. 56 FR 3064, January 28, 1991.) In view of the possible

redesign costs and the apparent lack of a safety need for a seat back

on boosters, NHTSA has tentatively determined that S5.2.1.1 should

provide that the 6-year-old dummy is not used to determine the

applicability of or compliance with the seat back requirements.

Comments are requested on this issue. NHTSA is particularly interested

in crash data indicating a need for a requirement for a seat back on

booster seats. Comments are also requested on any additional costs that

might result from redesigning child restraints to provide a seat back.

A requirement that currently differs accordingly to the test dummy

or dummies used in testing a child restraint, and would continue to do

so under this proposal, is that regarding post-impact buckle force

release (S5.4.3.5(b)). Currently, S5.4.3.5(b) requires each child seat

belt buckle to release when a force of not more than 16 pounds is

applied, while tension (simulating a child restrained in the child

seat) is applied to the buckle. Tension is applied because a child in

the seat could impose a load on the belt buckle which increases the

difficulty of releasing it. The test procedures for this requirement

(S6.2) specify that the applied tension is 20 pounds in the case of a

system tested with a 6-month-old dummy and 45 pounds in the case of a

system tested with a 3-year-old dummy. In both cases, the force level

is based on the heaviest children who are likely to use the restraint.

NHTSA proposes to amend S6.2 so that the tension would be 50 Newtons

when the system is tested with a newborn dummy, 90 Newtons for tests

with a 9-month-old dummy, 200 Newtons for tests with a 3-year-old

dummy, and 270 Newtons for tests with a 6-year-old dummy.

c. Clarifying Amendments

NHTSA is also proposing three clarifying amendments unrelated to

the addition of new sizes of dummies to Standard 213. Two of the

amendments would clarify the standard's excursion requirements. The

excursion requirement for built-in child restraints (S5.1.3.1(b))

prohibits the dummy's knee pivot from passing through a plane that is

specified distance ``forward of the hinge point of the specific vehicle

seat into which the system is built.'' Chrysler suggested (docket 74-

09-N24-001) that NHTSA amend the reference point because the ``hinge

point of the specific vehicle seat'' cannot be readily defined for most

vehicle seats. This is because most vehicle seats into which a built-in

child restraint is fabricated do not have hinges for their backs, or

are configured so that the hinge is not easily seen during dynamic

testing.

NHTSA is addressing this concern by proposing to reference the H-

point on the seat, which is a reference point used in S11 of Standard

208, ``Occupant Crash Protection,'' and in S4.3 of Standard 210, ``Seat

Belt Assembly Anchorages.'' The H-point of a specific vehicle seating

position is determined by using equipment and procedures specified in

the Society of Automotive Engineers (SAE) recommended practice SAE J826

(May 1987), ``Devices for Use in Defining and Measuring Vehicle Seating

Accommodation.'' The H-point is identified either during the seat's

design by means of a two-dimensional drafting template, or after the

vehicle is completely manufactured, by means of a three-dimensional

device. The H-point is located at approximately the same location as

the ``hinge point'' on a vehicle seat. However, since the H-point

already must be identified by the vehicle manufacturer for purposes of

Standards 208 and 210, it appears using the H-point for Standard 213

would be expedient.

The other clarifying amendment relates to the excursion requirement

for rear-facing child restraints (S5.1.3.2). S5.1.3.2 currently states

that ``no portion of the target point on either side of the dummy's

head'' shall pass through an area on the child restraint. The quoted

language would be revised to remove the reference to a ``portion'' of

the target point. The use of ``portion'' is incorrect since the target

point is dimensionless.

The third clarifying amendment relates to the requirement in the

standard that limits the force that may be imposed on a child from the

vehicle belt used to anchor the child seat to the vehicle (S5.4.3.2).

S5.4.3.2 currently limits the force that is imposed by ``each belt that

is part of a child restrain system and that is designed to restrain a

child using the system and to attach the system to the vehicle.'' NHTSA

proposes to also limit the force imposed by each Type 1 and the lap

portion of a Type 2 vehicle belt that is used to attach the child seat

to the vehicle. These belts, which anchor the child seat to the

vehicle, function to absorb the forces of the crash into the frame of

the vehicle. NHTSA is thus proposing that these belts not transfer

those crash forces to the occupant child.

d. Other Issues

The July 1991 planning document identified several possible ways in

which Standard 213 could be upgraded. These were incorporating the

newborn, 9-month-old and 6-year-old dummies, changing aspects of

Standard 213's test procedure (e.g., the characteristics of the seat

assembly used to test child seats and the severity of the dynamic

test); changing the injury criteria (HIC, chest g's); reducing

allowable head excursion; facilitating the manufacture of belt-

positioning child seats; and addressing the interaction of air bags and

infant seats. Since issuance of the planning document, some of these

issues have been addressed through the issuance of rulemaking notices,

such as today's NPRM and the September 1993 NPRM on belt-positioning

child seats. NHTSA has also issued an NPRM on the interaction of

airbags and infant seats (NPRM at 58 FR 19792; April 16, 1993).

All of the issues identified in the 1991 planning document as

subjects of possible rulemaking have been explored in research

projects. In some instances, research has shown that rulemaking does

not appear warranted. For example, NHTSA determined that the

configuration of today's vehicle interiors does not appear to pose a

safety need to reduce allowable head excursion. This is based on a

survey of late model vehicles that NHTSA conducted to assess vehicle

interior dimensions and the fit of the three-year-old and six-year-old

dummies, as well as on the fact that child restraints provide about 70

percent effectiveness in reducing serious injuries and fatalities when

used in today's vehicle interiors. The findings of the research were

summarized in a report titled, ``Assessment of Vehicle Interior

Dimensions and Lap/Shoulder Belt Fit,'' October 1992 (VRTC-82-0236,

``Child Restraint Testing (Rulemaking Support)''). Another example

where the agency's research has shown that rulemaking is not warranted

was research addressing whether flexibility of the back of the test

seat assembly affects that test dummy's performance during compliance

testing of shield-type booster seats. The findings of this research

were summarized in a report titled, ``Evaluation of Effects of FMVSS

213 Seat Back's Flexibility on Booster Seat Responses,'' October 1992,

(VRTC-82-0236, id.)

In other instances, more information on the issue is needed. For

instance, as mentioned in section IIb (``Performance criteria'') of

this preamble, information is generally unavailable on new, possibly

more appropriate injury criteria for children. Relatedly, new, more

sophisticated child test dummies are being developed, but more must be

known about their performance, reliability and availability as possible

Standard 213 test devices.

NHTSA also seeks to learn more about a particular type of child

restraining device that appears to be proliferating. These devices are

designed to be attached to a vehicle Type II belt system to improve the

fit of the system on children, and in some cases, on small adults. The

agency seeks information on whether Standard 213 should be applied to

these devices, and if so, which of the standard's requirements would be

appropriate for those devices.

The agency notes that the regulatory text proposed in this notice

includes language that was proposed in the September 1993 NPRM on child

booster seat safety. In some instances, comments were received on

aspects of the September 1993 NPRM that are included in today's NPRM.

For example, this notice includes text proposing specifications for the

seat belt anchorage points on the standard seat assembly used to test

belt-positioning booster seats. See proposed S6.1.1(c) of this notice.

The agency is including the text that was proposed in the earlier

notice simply to illustrate the complete appearance of the affected

section. The agency is fully aware of the issues raised by commenters

to various aspects of the September 1993 NPRM; it is not necessary for

commenters to resubmit views on today's notice that were expressed in

previous comments on the earlier NPRM. NHTSA emphasizes that inclusion

of text from the September 1993 notice does not imply that such text

will necessarily be adopted as proposed.

III. Rulemaking Analyses and Notices

Executive Order 12866 (Regulatory Planning and Review) and DOT

Regulatory Policies and Procedures

This rulemaking document was not reviewed under E.O. 12866,

``Regulatory Planning and Review.'' The agency has considered the

impact of this rulemaking action under the Department of

Transportation's regulatory policies and procedures, and has determined

that it is not ``significant'' under them. NHTSA has prepared a

preliminary regulatory evaluation for this action which discusses its

potential costs, benefits and other impacts. A copy of that evaluation

has been placed on the docket for this rulemaking action. Interested

persons may obtain copies of the evaluation by writing to the docket

section at the address provided at the beginning of this notice.

To briefly summarize the evaluation, cost estimates from NHTSA

contractor tests indicate that if two dummies were used to test each

adjustable position of each restraint, the cost per position would be

approximately $1,500. There are approximately 47 different models of

child restraints on the market, with an estimated total of 185

adjustable positions. The total cost for all manufacturers of testing

child restraints with two dummies instead of one would result in an

incremental increase of $138,750 ($750 x 185 adjustable positions).

Redesign costs are unknown, and have not been estimated. It appears

this rulemaking would affect shield-type boosters. Tests of some of

these boosters indicated that they generally could not adequately

restrain the nine-month-old and six-year-old test dummies, even though

they were recommended for children weighing the same as those dummies.

NHTSA believes that some manufacturers might cease producing shield

boosters that could not be certified as meeting Standard 213 when

tested with an additional dummy, rather than redesign the shield

boosters. The shield booster could be replaced with belt-positioning

boosters, which are relatively easy to design. Some manufacturers might

also relabel their restraints as being suitable for a narrower weight

range of children, to avoid having their restraints tested with a

particular test dummy (i.e., one representing a size of child that the

restraint cannot restrain). The cost impact of the rule on child

restraints other than shield boosters is unknown.

NHTSA cannot quantify the benefits of this rulemaking. However, the

agency believes this rulemaking would improve the safety of child

restraint systems by providing for their more thorough compliance

testing. The result of the rule would be to better ensure that each

child restraint safely restrains the children for whom the restraint is

recommended.

Regulatory Flexibility Act

NHTSA has considered the effects of this rulemaking action under

the Regulatory Flexibility Act. I hereby certify that it would not have

a significant economic impact on a substantial number of small

entities. The agency knows of fourteen manufacturers of child

restraints, seven of which NHTSA considers to be small businesses

(including Kolcraft, which with an estimated 500 employees, is on the

borderline of being a small business). A rule adopting today's

proposals would increase the testing that NHTSA conducts of child

restraints, which in turn would increase the certification

responsibilities of manufacturers. However, the agency does not believe

such an increase would constitute a significant economic impact on

small entities, because these businesses currently must certify their

products to the dynamic test of Standard 213. That is, the products of

these manufacturers already are subject to dynamic testing using child

test dummies. The effect of this rule on most child seats is to subject

them to testing with an additional dummy. Assuming there are shield

boosters that could not be certified as meeting Standard 213 when

tested with an additional dummy, small manufacturers producing those

boosters would have to redesign those restraints systems to meet the

standard. However, those manufacturers could decide to replace

nonconforming shield boosters with belt-positioning boosters, which are

relatively easy to design. NHTSA expects that all manufacturers will

enter the belt-positioning booster market. Some manufacturers might

also relabel their restraints as being suitable for a smaller weight

range of children, to avoid having their restraints tested with a

particular test dummy (i.e., one representing a size of child that the

restraint cannot restrain).

Small organizations and governmental jurisdictions might be

affected by a rule if these entities procure child restraint systems

for programs such as loaner programs. However, available information

indicates that only a small percentage of loaner programs carry booster

seats. Further, while the cost of child restraints could increase, the

agency believes the cost increase would be minimal. Thus, loaner

program procurements would not be significantly affected by a final

rule.

Executive Order 12612 (Federalism)

This rulemaking action has been analyzed in accordance with the

principles and criteria contained in Executive Order 12612, and the

agency has determined that this rule does not have sufficient

federalism implications to warrant the preparation of a Federalism

Assessment.

National Environmental Policy Act

NHTSA has analyzed this rulemaking action for the purposes of the

National Environmental Policy Act. The agency has determined that

implementation of this action would not have any significant impact on

the quality of the human environment.

Executive Order 12778 (Civil Justice Reform)

This proposed rule does not have any retroactive effect. Under

section 103(d) of the National Traffic and Motor Vehicle Safety Act

(Safety Act; 15 U.S.C. 1392(d)), whenever a Federal motor vehicle

safety standard is in effect, a state may not adopt or maintain a

safety standard applicable to the same aspect of performance which is

not identical to the Federal standard, except to the extent that the

state requirement imposes a higher level of performance and applies

only to vehicles procured for the State's use. Section 105 of the

Safety Act (15 U.S.C. 1394) sets forth a procedure for judicial review

of final rules establishing, amending or revoking Federal motor vehicle

safety standards. That section does not require submission of a

petition for reconsideration or other administrative proceedings before

parties may file suit in court.

IV. Comments on the Proposal

Interested persons are invited to submit comments on the proposal.

It is requested, but not required, that 10 copies be submitted.

All comments must not exceed 15 pages in length. (49 CFR 553.21).

Necessary attachments may be appended to these submissions without

regard to the 15-page limit. This limitation is intended to encourage

commenters to detail their primary arguments in a concise fashion.

If a commenter wishes to submit certain information under a claim

of confidentiality, three copies of the complete submission, including

purportedly confidential business information, should be submitted to

the Chief Counsel, NHTSA, at the street address given above, and seven

copies from which the purportedly confidential information has been

deleted should be submitted to the Docket Section. A request for

confidentiality should be accompanied by a cover letter setting forth

the information specified in the agency's confidential business

information regulation. 49 CFR Part 512.

All comments received before the close of business on the comment

closing date indicated above for the proposal will be considered, and

will be available for examination in the docket at the above address

both before and after that date. To the extent possible, comments filed

after the closing date will also be considered. Comments received too

late for consideration in regard to the final rule will be considered

as suggestions for further rulemaking action. Comments on the proposal

will be available for inspection in the docket. The NHTSA will continue

to file relevant information as it becomes available in the docket

after the closing date, and it is recommended that interested persons

continue to examine the docket for new material.

Those persons desiring to be notified upon receipt of their

comments in the rules docket should enclose a self-addressed, stamped

postcard in the envelope with their comments. Upon receiving the

comments, the docket supervisor will return the postcard by mail.

List of Subjects in 49 CFR Part 571

Imports, Motor vehicle safety, Motor vehicles.

In consideration of the foregoing, NHTSA proposes to amend 49 CFR

part 571 as set forth below.

PART 571--FEDERAL MOTOR VEHICLE SAFETY STANDARDS

1. The authority citation for part 571 would continue to read as

follows:

Authority: 15 U.S.C. 1392, 1401, 1403, 1407; delegation of

authority at 49 CFR 1.50.

2. Section 571.213 would be amended by--

a. revising S5, S5.1.3.1 (a) and (b), S5.1.3.2, the introductory

paragraph of S5.2.1.2, S5.4.3.2, the introductory text of S5.4.3.5,

S5.4.3.5 (a) and (b), S5.5.2(f), S5.5.5(f), S6 through S6.1.2, S6.2.2,

S6.2.3, S7 through S7.2, S8.2.1, S8.2.3, and S8.2.4,

b. removing S6.1.2.1 through S6.1.2.6 and S7.2.1 through S7.3, and

c. adding S9 and S10, to read as follows:

Sec. 571.213 Standard No. 213, Child restraint systems.

* * * * *

S5. Requirements. (a) Each motor vehicle with a built-in child

restraint system shall meet the requirements in this section when, as

specified, tested in accordance with S6.1 and this paragraph.

(b) Each child restraint system manufactured for use in motor

vehicles shall meet the requirements in this section when, as

specified, tested in accordance with S6.1 and this paragraph. Each add-

on system shall meet the requirements at each of the restraint's seat

back angle adjustment positions and restraint belt routing positions,

when the restraint is oriented in the direction recommended by the

manufacturer (e.g., forward, rearward or laterally) pursuant to S5.6,

and tested with the test dummy specified in S7.

(c) Each child restraint system manufactured for use in aircraft

shall meet the requirements in this section and the additional

requirements in S8.

* * * * *

S5.1.3.1 * * *

(a) In the case of an add-on child restraint system, no portion of

the test dummy's head shall pass through a vertical, transverse plane

that is 813 millimeters forward of point Z on the standard seat

assembly, measured along the center SORL (as illustrated in figure 1B),

and neither knee pivot point shall pass through a vertical, transverse

plane that is 914 millimeters forward of point Z on the standard seat

assembly, measured along the center SORL.

(b) In the case of a built-in child restraint system, neither knee

pivot shall pass through a vertical, transverse plane that is 686

millimeters forward of the H-Point as described in the Society of

Automotive Engineers Recommended Practice ``Devices for Use in Defining

and Measuring Vehicle Seating Accommodation,'' SAE J826, May 1987

(specified in ``S4.3.2, Seat Belt Anchorages for the Upper Torso

Portion of Type 2 Seat Belt Assemblies,'' of 49 CFR (Sec. 571.210),

Seat Belt Assembly Anchorages) of the specific passenger car seat into

which the system is built, measured along a horizontal line passing

through the H-Point and parallel to the vehicle's longitudinal center

plane.

S5.1.3.2 Rear-facing child restraint systems. In the case of each

rear-facing child restraint system, all portions of the test dummy's

torso shall be retained within the system and neither of the target

points on either side of the dummy's head and on the transverse axis

passing through the center of gravity of the dummy's head and

perpendicular to the head's midsagittal plane, shall pass through the

transverse orthogonal planes whose intersection contains the forward-

most and top-most points on the child restraint system surfaces

(illustrated in Figure 1C).

* * * * *

S5.2.1.2 The applicability of the requirements of S5.2.1.1 to a

front-facing child restraint, and the conformance of any child

restraint other than a car bed to those requirements is determined

using the largest of the test dummies specified in S7.1 for use in

testing that restraint; provided, that the 6-year-old dummy described

in subpart I of part 572 of this title is not used to determine the

applicability of or compliance with S5.2.1.1. A front-facing child

restraint system is not required to comply with S5.2.1.1 if the target

point on either side of the dummy's head is below a horizontal plane

tangent to the top of--

* * * * *

S5.4.3.2 Direct restraint. Each belt that is part of a child

restraint system and that is designed to restrain a child using the

system and to attach the system to the vehicle, and each Type 1 and lap

portion of a Type 2 vehicle belt that is used to attach the system to

the vehicle shall, when tested in accordance with S6.1, impose no loads

on the child that result from the mass of the system, or

(a) In the case of an add-on child restraint system, from the mass

of the seat back of the standard seat assembly specified in S6.1, or

(b) In the case of a built-in child restraint system, from the mass

of any part of the vehicle into which the child restraint system is

built.

* * * * *

S5.4.3.5 Buckle release. Any buckle in a child restraint system

belt assembly designed to restrain a child using the system shall:

(a) When tested in accordance with S6.2.1 prior to the dynamic test

of S6.1, not release when a force of less than 40 Newtons is applied

and shall release when a force of not more than 62 Newtons is applied;

(b) After the dynamic test of S6.1, when tested in accordance with

the appropriate sections of S6.2, release when a force of not more than

71 Newtons is applied;

* * * * *

S5.5.2 * * *

(f) One of the following statements, inserting the manufacturer's

recommendations for the maximum weight and sitting height of children

who can safely occupy the system:

(1) This infant restraint is designed for use by children who weigh

________ pounds or less and whose sitting height is ________ inches or

less (the sitting height of a seated child is measured from the seating

surface to the top of the child's head); or

(2) This child restraint is designed for use only by children who

weigh between ________ and ________ pounds and whose sitting height is

________ inches or less and who are capable of sitting upright alone

(the sitting height of a seated child is measured from the seating

surface to the top of the child's head); or

(3) This child restraint is designed for use only by children who

weigh between ________ and ________ pounds and whose sitting height is

between ________ and ________ inches (the sitting height of a seated

child is measured from the seating surface to the top of the child's

head).

* * * * *

S5.5.5 * * *

(f) One of the following statements, inserting the manufacturer's

recommendations for the maximum weight and sitting height of children

who can safely occupy the system:

(1) This infant restraint is designed for use by children who weigh

________ pounds or less and whose sitting height is ________ inches or

less (the sitting height of a seated child is measured from the seating

surface to the top of the child's head); or

(2) This child restraint is designed for use only by children who

weigh between ________ and ________ pounds and whose sitting height is

________ inches or less and who are capable of sitting upright alone

(the sitting height of a seated child is measured from the seating

surface to the top of the child's head); or

(3) This child restraint is designed for use only by children who

weigh between ________ and ________ pounds and whose sitting height is

between ________ and ________ inches (the sitting height of a seated

child is measured from the seating surface to the top of the child's

head).

* * * * *

S6. Test conditions and procedures. S6.1 Dynamic systems test for

child restraint systems.

The test conditions described in S6.1.1 apply to the dynamic

systems test. The test procedure for the dynamic systems test is

specified in S6.1.2. The test dummy specified in S7 is placed in the

test specimen (child restraint), clothed as described in S9 and

positioned according to S10.

6.1.1 Test conditions. (a) Test devices. (1) The test device for

add-on restraint systems is a standard seat assembly consisting of a

simulated vehicle bench seat, with three seating positions, which is

described in Drawing Package SAS-100-1000, addendum A (dated July 1,

1993) (consisting of drawings and a bill of materials). The assembly is

mounted on a dynamic test platform so that the center SORL of the seat

is parallel to the direction of the test platform travel and so that

movement between the base of the assembly and the platform is

prevented.

(2) The test device for built-in child restraint systems is either

the specific vehicle shell or the specific vehicle.

(i) Specific vehicle shell. (A) The specific vehicle shell, if

selected for testing, is mounted on a dynamic test platform so that the

longitudinal center line of the shell is parallel to the direction of

the test platform travel and so that movement between the base of the

shell and the platform is prevented. Adjustable seats are in the

adjustment position midway between the forwardmost and rearmost

positions, and if separately adjustable in a vertical direction, are at

the lowest position. If an adjustment position does not exist midway

between the forwardmost and rearmost position, the closest adjustment

position to the rear of the midpoint is used. Adjustable seat backs are

in the manufacturer's nominal design riding position. If such a

position is not specified, the seat back is positioned so that the

longitudinal center line of the child test dummy's neck is vertical,

and if an instrumented test dummy is used, the accelerometer surfaces

in the dummy's head and thorax, as positioned in the vehicle, are

horizontal. If the vehicle seat is equipped with adjustable head

restraints, each is adjusted to its highest adjustment position.

(B) The platform is instrumented with an accelerometer and data

processing system having a frequency response of 60 Hz channel class as

specified in Society of Automotive Engineers Recommended Practice J211

JUN80 ``Instrumentation for Impact Tests.'' The accelerometer sensitive

axis is parallel to the direction of test platform travel.

(ii) Specific vehicle. For built-in child restraint systems, an

alternate test device is the specific vehicle into which the built-in

system is fabricated. The following test conditions apply to this

alternate test device.

(A) The vehicle is loaded to its unloaded vehicle weight plus its

rated cargo and luggage capacity weight, secured in the luggage area,

plus the appropriate child test dummy and, at the vehicle

manufacturer's option, an anthropomorphic test dummy which conforms to

the requirements of subpart B or subpart E of part 572 of this title

for a 50th percentile adult male dummy placed in the front outboard

seating position. If the built-in child restraint system is installed

at one of the seating positions otherwise requiring the placement of a

part 572 test dummy, then in the frontal barrier crash specified in

(c), the appropriate child test dummy shall be substituted for the part

572 adult dummy, but only at that seating position. The fuel tank is

filled to any level from 90 to 95 percent of capacity.

(B) Adjustable seats are in the adjustment position midway between

the forward-most and rearmost positions, and if separately adjustable

in a vehicle direction, are at the lowest position. If an adjustment

position does not exist midway between the forward-most and rearmost

positions, the closest adjustment position to the rear of the midpoint

is used.

(C) Adjustable seat backs are in the manufacturer's nominal design

riding position. If a nominal position is not specified, the seat back

is positioned so that the longitudinal center line of the child test

dummy's neck is vertical, and if an anthropomorphic test dummy is used,

the accelerometer surfaces in the test dummy's head and thorax, as

positioned in the vehicle, are horizontal. If the vehicle is equipped

with adjustable head restraints, each is adjusted to its highest

adjustment position.

(D) Movable vehicle windows and vents are, at the manufacturer's

option placed in the fully closed position.

(E) Convertibles and open-body type vehicles have the top, if any,

in place in the closed passenger compartment configuration.

(F) Doors are fully closed and latched but not locked.

(G) All instrumentation and data reduction is in conformance with

SAE J211 JUN80.

(b) the tests are frontal barrier impact simulations of the test

platform or frontal barrier crashes of the specific vehicles as

specified in S5.1 (Sec. 571.208) and for:

(1) Test Configuration I, are at a velocity change of 30 mph with

the acceleration of the test platform entirely within the curve shown

in Figure 2, or for the specific vehicle test with the deceleration

produced in a 30 mph frontal barrier crash.

(2) Test Configuration II, are set at a velocity change of 20 mph

with the acceleration of the test platform entirely within the curve

shown in Figure 3, or for the specific vehicle test, with the

deceleration produced in a 20 mph frontal barrier crash.

(c) Attached to the seat belt anchorage points provided on the

standard seat assembly (illustrated in Figures 1A and 1B) are Type 1

seat belt assemblies in the case of add-on child restraint systems

other than belt-positioning seats, or Type 2 seat belt assemblies in

the case of belt-positioning seats. These seat belt assemblies meet the

requirements of Standard No. 209 (Sec. 571.209) and have webbing with a

width of not more than 2 inches, and are attached to the anchorage

points without the use of retractors or reels of any kind.

(d) Performance tests under S6.1 are conducted at any ambient

temperature from 19 deg. to 26 deg. F and at any relative humidity from

10 percent to 70 percent.

(e) In the case of add-on child restraint systems, the restraint

shall meet the requirements of S5 at each of its seat back angle

adjustment positions and restraint belt routing positions, when the

restraint is oriented in the direction recommended by the manufacturer

(e.g., forward, rearward or laterally) pursuant to S5.6, and tested

with the test dummy specified in S7.

S6.1.2 Dynamic test procedure.

(a) Activate the built-in child restraint or attach the add-on

child restraint to the seat assembly as described below: (1) Test

configuration I. (i) In the case of each add-on child restraint system

other than a belt-positioning seat, child harness, a booster seat with

a top anchorage strap, or a restraint designed for use by physically

handicapped children, install a new add-on child restraint system at

the center seating position of the standard seat assembly in accordance

with the manufacturer's instructions provided with the system pursuant

to S5.6.1, except that the add-on restraint shall be secured to the

standard vehicle seat using only the standard vehicle lap belt. A child

harness, a booster seat (other than a belt-positioning seat) with a top

anchorage strap, or a restraint designed for use by physically

handicapped children shall be installed at the center seating position

of the standard seat assembly in accordance with the manufacturer's

instructions provided with the system pursuant to S5.6.1. A belt-

positioning seat shall be installed at either outboard seating position

of the standard seat assembly in accordance with the manufacturer's

instructions provided with the system pursuant to S5.6.1, except that

the belt-positioning seat shall be secured to the standard vehicle seat

using only the standard vehicle lap and shoulder belt.

(ii) In the case of each built-in child restraint system, activate

the restraint in the specific vehicle shell or the specific vehicle, in

accordance with the manufacturer's instructions provided in accordance

with S5.6.2.

(2) Test configuration II. (i) In the case of each add-on child

restraint system which is equipped with a fixed or movable surface

described in S5.2.2.2, or a booster seat with a top anchorage strap,

install a new add-on child restraint system at the center seating

position of the standard seat assembly using only the standard seat lap

belt to secure the system to the standard seat.

(ii) In the case of each built-in child restraint system which is

equipped with a fixed or movable surface described in S5.2.2.2, or a

built-in booster seat with a top anchorage strap, activate the system

in the specific vehicle shell or the specific vehicle in accordance

with the manufacturer's instructions provided in accordance with

S5.6.2.

(b) Tighten all belts used to attach the add-on child restraint

system to the standard seat assembly to a tension of not less than 53.5

Newtons and not more than 67 Newtons, as measured by a load cell used

on the webbing portion of the belt.

(c) Place in the child restraint any dummy specified in S7 for

testing systems for use by children of the heights and weights for

which the system is recommended in accordance with S5.6.

(d) Assemble, clothe, prepare and position the dummy as specified

in S7 through S10 and part 572 of this chapter, as appropriate.

(e) If provided, shoulder and pelvic belts that directly restrain

the dummy in add-on and built-in systems shall be adjusted as follows:

Tighten the belts until a 9-Newton force applied (as illustrated in

figure 5) to the webbing at the top of each dummy shoulder and to the

pelvic webbing 50 millimeters on either side of the torso midsagittal

plane pulls the webbing 7 millimeters from the dummy.

(f) Accelerate the test platform to simulate frontal impact in

accordance with Test Configuration I or II, as appropriate.

(g) Determine conformance with the requirements in S5.1, as

appropriate.

* * * * *

S6.2.2 After completion of the testing specified in S6.1 and

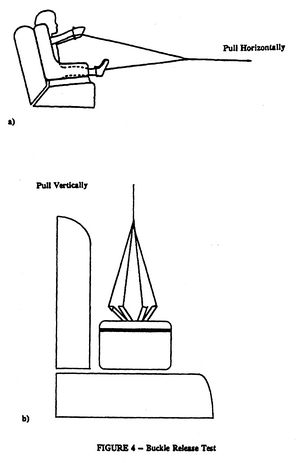

before the buckle is unlatched, tie a self-adjusting sling to each

wrist and ankle of the test dummy in the manner illustrated in Figure

4, without disturbing the belted dummy and the child restraint system.

S6.2.3 Pull the sling tied to the dummy restrained in the child

restraint system and apply a force whose magnitude is: 50 Newtons for a

system tested with a newborn dummy; 90 Newtons for a system tested with

a 9-month-old dummy; 200 Newtons for a system tested with a 3-year-old

dummy; or 270 Newtons for a system tested with a 6-year-old dummy. The

force is applied in the manner illustrated in Figure 4 and as follows:

(a) Add-on Child Restraints. For an add-on child restraint other

than a car bed, apply the specified force by pulling the sling

horizontally and parallel to the SORL of the standard seat assembly.

For a car bed, apply the force by pulling the sling vertically.

(b) Built-in Child Restraints. For a built-in child restraint other

than a car bed, apply the force by pulling the sling parallel to the

longitudinal center line of the specific vehicle shell or the specific

vehicle. In the case of a car bed, apply the force by pulling the sling

vertically.

* * * * *

S7. Test dummies. (Subparts referenced in this section are of part

572 of this chapter.) S7.1 Dummy selection. (a) A child restraint that

is recommended by its manufacturer in accordance with S5.5 for use

either by children in a specified mass range that includes any children

having a mass less than 4 kilograms, or by children in a specified

sitting height range that includes any children whose sitting height is

equal to or less than 450 mm, is tested with a newborn test dummy

conforming to part 572 subpart K.

(b) A child restraint that is recommended by its manufacturer in

accordance with S5.5 for use either by children in a specified mass

range that includes any children having a mass equal to or greater than

4 but less than 9 kilograms, or by children in a specified sitting

height range that includes any children whose sitting height is greater

than 450 mm but not greater than 500 mm, is tested with a newborn test

dummy conforming to part 572 subpart K, and a 9-month-old test dummy

conforming to part 572 subpart J.

(c) A child restraint that is recommended by its manufacturer in

accordance with S5.5 for use either by children in a specified mass

range that includes any children having a mass equal to or greater than

9 but not greater than 13.5 kilograms, or by children in a specified

sitting height range that includes any children whose sitting height is

greater than 500 mm but not greater than 600 mm, is tested with a 9-

month-old test dummy conforming to part 572 subpart J, and a 3-year-old

test dummy conforming to part 572 subpart C and S7.2.

(d) A child restraint that is recommended by its manufacturer in

accordance with S5.5 for use either by children in a specified mass

range that includes any children having a mass greater than 13.5

kilograms, or by children in a specified sitting height range that

includes any children whose sitting height is greater than 600 mm, is

tested with a 3-year-old test dummy conforming to part 572 subpart C

and S7.2, and a 6-year-old test dummy conforming to part 572 subpart I.

(e) A child restraint that meets the criteria in two or more of the

preceding paragraphs in S7.1 is tested with each of the test dummies

specified in those paragraphs.

S7.2 Three-year-old dummy head. Effective September 1, 1993, this

dummy is assembled with the head assembly specified in

Sec. 572.16(a)(1) of this chapter.

* * * * *

S8.2.1 A standard seat assembly consisting of a representative

aircraft passenger seat shall be positioned and adjusted so that its

horizontal and vertical orientation and its seat back angle are the

same as shown in Figure 6.

* * * * *

S8.2.3 In accordance with S10, place in the child restraint any

dummy specified in S7 for testing systems for use by children of the

heights and weights for which the system is recommended in accordance

with S5.5 and S8.1.

S8.2.4 If provided, shoulder and pelvic belts that directly

restrain the dummy shall be adjusted in accordance with S6.1.2.

* * * * *

S9 Dummy clothing and preparation. S9.1 Type of clothing. (a)

Newborn dummy. When used in testing under this standard, the dummy is

unclothed.

(b) Nine-month-old dummy. When used in testing under this standard,

the dummy is clothed in terry cloth polyester and cotton size 1 long

sleeve shirt and size 1 long pants, with a total mass of 0.136

kilograms.

(c) Three-year-old and six-year-old dummies. When used in testing

under this standard, the dummy is clothed in thermal knit, waffle-weave

polyester and cotton underwear or equivalent, a size 4 long-sleeved

shirt (3-year-old dummy) or a size 5 long-sleeved shirt (6-year-old

dummy) having a mass of 0.090 kilograms, a size 4 pair of long pants

having a mass of 0.090 kilograms and cut off just far enough above the

knee to allow the knee target to be visible, and size 7M sneakers (3-

year-old dummy) or size 12\1/2\ sneakers (6-year-old dummy) with rubber

toe caps, uppers of dacron and cotton or nylon and a total mass of

0.453 kilograms.

S9.2 Preparing clothing. Clothing other than the shoes is machine-

washed in 71 deg. C to 82 deg. C and machine-dried at 49 deg. C to

60 deg. C for 30 minutes.

S9.3 Preparing dummies. Before being used in testing under this

standard, dummies must be conditioned at any ambient temperature from

19 deg. C to 25.5 deg. C and at any relative humidity from 10 percent

to 70 percent for at least 4 hours.

S10. Positioning the dummy and attaching the system belts. S10.1

Car beds. Place the test dummy in the car bed in the supine position

with its midsagittal plane perpendicular to the center SORL of the

standard seat assembly, in the case of an add-on car bed, or

perpendicular to the longitudinal axis of the specific vehicle shell or

the specific vehicle, in the case of a built-in car bed. Position the

dummy within the car bed in accordance with the instructions for child

positioning that the bed manufacturer provided with the bed in

accordance with S5.6.

S10.2 Restraints other than car beds. S10.2.1 Newborn dummy and

nine-month-old dummy. Position the test dummy according to the

instructions for child positioning that the manufacturer provided with

the system under S5.6.1 or S5.6.2, while conforming to the following:

(a) Prior to placing the 9-month-old test dummy in the child restraint

system, place the dummy in the supine position on a horizontal surface.

While placing a hand on the center of the torso to prevent movement of

the dummy torso, rotate the dummy legs upward by lifting the feet 90

degrees. Slowly release the legs but do not return them to the flat

surface.

(b)(1) When testing forward-facing child restraint systems, holding

the 9-month-old test dummy torso upright until it contacts the system's

design seating surface, place the 9-month-old test dummy in the seated

position within the system with the mid-sagittal plane of the dummy

head--

(i) Coincident with the center SORL of the standard seating

assembly, in the case of the add-on child restraint system, or

(ii) Vertical and parallel to the longitudinal center line of the

specific vehicle shell or the specific vehicle, in the case of a built-

in child restraint system.