Federal Motor Vehicle Safety Standards; Door Locks and Door Retention Components |

|---|

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

|

Barry Felrice

Federal Register

August 30, 1994

[Federal Register: August 30, 1994]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 94-70; Notice 1]

RIN 2127-AF35

Federal Motor Vehicle Safety Standards; Door Locks and Door

Retention Components

AGENCY: National Highway Traffic Safety Administration (NHTSA),

Department of Transportation (DOT).

ACTION: Notice of Proposed Rulemaking.

-----------------------------------------------------------------------

SUMMARY: This document proposes to amend Federal Motor Vehicle Safety

Standard No. 206, Door Locks and Door Retention Components, by

extending and expanding the standard's existing side door requirements

to the back doors of passenger cars and multipurpose passenger vehicles

with a gross vehicle weight rating (GVWR) of 4,536 kilograms (kg)

(10,000 pounds (lb)) or less, including hatchbacks, station wagons,

sport utility vehicles, and passenger vans. The purpose of the

standard's requirements, which currently apply only to side doors, is

to reduce the likelihood of occupants being ejected from vehicles in

real-world crashes. A recent agency study indicates that each year

there are nearly 150 fatalities in which an occupant is ejected through

rear hatches, tailgates, and other back doors of these vehicles. This

proposal seeks to reduce the number of fatalities and serious injuries

resulting from such ejections by extending and expanding Standard No.

206's requirements for door locks and door retention components to back

doors. Given the differences between side doors and back doors, the

agency is proposing minor modifications in the performance requirements

and test procedures to make them appropriate for back doors.

DATES: Comment closing date: Comments on this notice must be received

by NHTSA not later than October 31, 1994.

Proposed effective date: The agency is considering an effective

date of the first September 1 that occurs following a two year period

beginning with the publication of a final rule in the Federal Register.

ADDRESSES: Comments should refer to the docket and notice numbers set

forth above and be submitted to: Docket Section, National Highway

Traffic Safety Administration, 400 Seventh Street, SW., Room 5109,

Washington, DC 20590. Docket room hours are from 9:30 a.m. to 4:00

p.m., Monday through Friday.

FOR FURTHER INFORMATION CONTACT: Dr. Joseph Kanianthra, Chief, Side and

Rollover Crash Protection Division, Office of Vehicle Safety Standards,

National Highway Traffic Safety Administration, 400 Seventh Street,

SW., Washington, DC 20590, (202) 366-4924.

SUPPLEMENTARY INFORMATION:

I. Background

A. The Existing Standard

B. April 1990 Report

C. June 1990 Petition for Rulemaking

D. Events Since 1990

II. Proposal

A. Overall Proposal and Rationale

B. Door Latches

1. Requirements for Secondary Latch Position

2. Load Requirements

C. Door Hinges

D. Door Locks

E. Leadtime

F. Additional Considerations/Questions

III. Costs

IV. Rulemaking Analyses and Notices

A. E.O. 12866 and DOT Regulatory Policies and Procedures

B. Regulatory Flexibility Act

C. National Environmental Policy Act

D. E.O. 12612, Federalism

E. Civil Justice Reform

V. Comments

I. Background

A. The Existing Standard

Standard No. 206, Door Locks and Door Retention Components,

specifies performance requirements for side door locks and side door

retention components, including latches, hinges, and other supporting

means. The requirements are intended to minimize the likelihood of

occupant ejections from the vehicle in the event of a crash.

The standard's full requirements apply to side doors other than

cargo-type doors and sliding doors; more abbreviated requirements apply

to the latter two types of doors. The standard's full requirements can

be summarized as follows.

First, each door latch and striker assembly must have a fully

latched position and a secondary latch position. The secondary position

serves as a backup to the primary latched position in the event the

primary latch is not properly engaged and adds an additional level of

protection in case the primary latch position fails.

Second, latches and hinges must withstand specified load

requirements. A door latch and striker assembly of a side door, when in

the fully latched position, must not separate when a longitudinal load

of 11,000 Newtons (2,500 pounds), or a transverse load of 8,900 Newtons

(2,000 pounds), is applied to the latch (``Longitudinal'' loads are

parallel to the vehicle's longitudinal centerline and are applied

perpendicular to the face of the latch. ``Transverse'' loads are

perpendicular to the vehicle centerline and are applied in the

direction in which the door opens). Reduced load requirements are

specified for the secondary latched position. Also, a door latch must

not disengage from the fully latched position when specified inertia

loads are applied to the door latch system (Inertia is the property of

matter that requires that a load be exerted on a body to accelerate it.

An inertial load is calculated by multiplying the mass of a body by its

acceleration). Door hinges must not separate when specified

longitudinal and transverse loads are applied to the hinge system.

Third, side doors must be equipped with a locking mechanism with an

operating means in the interior of the vehicle. For side front door

locks, the outside door handle must be inoperative when the locking

mechanism is engaged. For side rear door locks, both the outside and

inside door handles must be inoperative when the locking mechanism is

engaged.

Standard No. 206 specifies test procedures for many of its

performance requirements. The standard incorporates test procedures set

forth in two Society of Automotive Engineers (SAE) recommended

practices: SAE J839b, Passenger Car Side Door Latch Systems, and SAE

J934, Vehicle Passenger Door Hinge Systems.

B. April 1990 Report

As part of its review of potential back door safety problems, NHTSA

conducted an in-depth accident analysis using 1982-1986 and 1988 (no

national data file for 1987) National Accident Sampling System (NASS)

data relating to door openings and ejections in passenger vehicles

involved in crashes that required towing from the scene (hereinafter

referred to as towaway crashes). In addition, the 1988 Fatal Accident

Reporting System (FARS) data were used to assess the magnitude of the

safety problem. The results of these analyses were published on April

5, 1990 in a report entitled ``Hatchback, Tailgate, and Back Door

Opening in Crashes and Occupant Ejection through the Back Area'' (1990

Report). A copy of this report is available in NHTSA Docket 90-08-GR-

001.

The report concluded that back doors of vehicles so equipped open

in 5-6 percent of towaway crashes, compared to 1-2 percent of side

doors in such crashes. Further, a hatchback or tailgate was about 3

times as likely to open as one of the front side doors and about 7-8

times as likely to open as one of the rear side doors. Of passenger

vehicles so equipped, an estimated 36,244 hatchbacks and tailgates

opened in towaway crashes in 1988. More specifically, an estimated

4,986 passenger van back doors opened in towaway crashes, representing

about 4 times the rate of front side door openings and about double the

rate of right rear side door openings (very few passenger vans have

left side rear doors).

Finally, the data showed that 53 percent of the back door openings

occurred in accidents involving vehicle rollovers, as opposed to 23

percent of left front door openings and 40 percent of right front door

openings.

Despite the frequency of back door openings, however, occupant

ejection through the back door occurred in only 1 percent of the

towaway crashes involving back door openings. This compares with 8 to

13 percent of occupant ejections through front door openings.

FARS data indicated that there were 8,343 passenger car and MPV

occupant ejection fatalities in 1988, 2,190 of which were from vehicles

with back doors. NHTSA's report set forth two methodologies, both using

NASS data, to estimate the number of these fatalities that represented

occupant ejections through back doors. One methodology resulted in an

estimate that 93 of the fatally injured persons were ejected through

back doors. The other methodology estimated the number to be 130.

Also on April 5, 1990, NHTSA wrote to nine manufacturers (Chrysler,

Ford, General Motors, Honda, Mazda, Nissan, Toyota, Volkswagen, and

Volvo) asking their thoughts on how to address the problem of back door

openings and requesting information on design specifications used for

the production of back door latch/lock systems. Eight of the nine

responded, indicating that none of their back door latch assemblies,

except certain Mazda vehicles, met the requirements of Standard No.

206.

They stated that they did not consider back door openings to be a

significant safety problem, however, and indicated that they had

certain design guidelines and requirements that are followed in

designing their back door latch assemblies. Finally, they stated that

proper use of seat belts is the most effective method of ejection

reduction.

C. June 1990 Petition for Rulemaking

On June 19, 1990, the Insurance Institute for Highway Safety

petitioned the agency to, among other things, extend the requirements

of Standard 206 to back doors. NHTSA denied this petition in a document

published in the Federal Register (55 FR 48261) on November 20, 1990,

citing the 1990 Report in its denial. NHTSA concluded that increased

use of seat belts would be a more effective means of reducing back door

ejections than extending the requirements of Standard 206 to back

doors, and that there was not a safety need significant enough to

justify the recommended rulemaking.

D. Events Since 1990

NHTSA continued to evaluate the issue of preventing back door

ejections and on January 21, 1994, issued an update to the 1990 Report.

The updated report is entitled ``Door Opening and Occupant Ejection

through Rear Hatches, Tailgates, and Other Back Doors'' (1994 Report).

The agency published a notice in the Federal Register (59 FR 3925) on

January 27, 1994, requesting public review and comment on this report.

This report is available in Docket No. 90-06-No.3-001.

NASS and FARS data from 1988-1992 were utilized for this report.

Based on an analysis of those data, the report estimated that each year

there are 147 fatalities in which occupants are ejected through rear

hatches, tailgates and other back doors. The data also showed that

approximately 95 percent of the victims were not secured by seat belts

and that approximately 10 percent of those victims were children under

10 years of age.

In towaway crashes, rollovers accounted for 35 percent of left

front door openings, 40 percent of right front door openings, and 42

percent of back door openings. Also, the data showed that the most

common damage associated with door openings was damage to the latch and

striker assemblies. This was true for 60 percent of opened left front

doors, 50 percent of opened right front doors, and 71 percent of opened

back doors.

Three comments were received in response to NHTSA's January 1994

notice. The American Automobile Manufacturers Association (AAMA) stated

that the report showed a low rate of passenger ejection through back

doors, and contended that the data again demonstrate that the most

effective means of preventing back door ejections is through the proper

use of safety belts. AAMA encouraged NHTSA's efforts in promoting the

use of safety belts.

Advocates for Highway and Auto Safety (Advocates) agreed that a

high percentage of vehicle ejections occur because of lack of use or

improper use of safety belts. Nevertheless, Advocates believes that

back doors are opening at an unacceptable rate. To address this

problem, Advocates suggested that NHTSA should take multiple actions.

That organization stated that NHTSA should look at the fundamental

character of latch/striker designs in addition to increasing latch/

striker strength. Further, Advocates stated that NHTSA should address

the current roof strength and side impact standards as they relate to

latch/striker integrity. Finally, Advocates stated that because rear

seat belts in some vehicles are insufficient to assure ready

availability to occupants, NHTSA should address that issue as well as

evaluate how rear seats themselves are attached in MPVs.

A comment was also submitted by Mr. Nicholas Perrone of Perrone

Forensic Consulting, Inc., and Mssrs. Clarence Ditlow and Ray Gold of

the Center for Auto Safety. They stated that the sum of injuries and

fatalities from back door ejections would approach 1,000 per year. They

attached two case studies of back door ejections. These commenters

suggested that the Standard No. 206 test be changed, that the standard

be extended to back doors, that laminated glass should be used for all

fixed windows, that side and roof strength for vehicles with high

centers of gravity should be improved, and that back door structures

have dynamic integrity.

II. Proposal

A. Overall Proposal and Rationale

In light of the number of fatalities that are occurring as a result

of back door ejections, NHTSA has decided to propose extending and

expanding Standard No. 206's side door requirements to the back doors

of passenger cars and multipurpose passenger vehicles (MPVs) with a

GVWR of 4,536 kg (10,000 lb) or less, including hatchbacks, station

wagons, sport utility vehicles, and passenger vans. Given the

differences between side doors and back doors in the orientation of

their hinges and latches in relation to the vehicle, the agency is

proposing modifications to the test requirements/procedures to make

them appropriate for back doors.

NHTSA has previously concluded that Standard No. 206's requirements

have been effective in reducing side door ejections. In November 1989,

the agency published ``An Evaluation of Door Locks and Roof Crush

Resistance of Passenger Cars--Federal Motor Vehicle Safety Standards

206 and 216 (DOT HS 806 489).'' The study concluded that door latch

improvements in passenger cars implemented during 1963-68 save an

estimated 400 lives per year, reducing the risk of ejection in rollover

crashes by 15 percent.

NHTSA believes that extending the existing requirements of Standard

No. 206 to back doors would make an additional contribution toward

reducing injuries and perhaps fatalities caused by back door ejections.

The agency recognizes that the increased use of seat belts is also an

effective means of addressing this problem. However, despite continuing

efforts by NHTSA, state and local governments, safety organizations,

manufacturers and others to promote safety belt use, fatalities

resulting from the ejection of unbelted occupants remain a serious

safety problem. Therefore, while the agency recognizes the importance

of continuing efforts to increase safety belt use, it now believes that

an extension and expansion of Standard No. 206's requirements to back

doors is appropriate as well. The agency also believes that, given the

increasing popularity of vehicles with back doors, especially vans,

this safety problem may become more serious unless action is taken.

NHTSA also notes that the agency is in the process of conducting

additional research examining the potential for improving vehicle latch

performance. While that research may lead to a future upgrade of

Standard No. 206, the agency does not believe it should delay the

application of the standard's existing and/or modified requirements to

back doors in the interim. The agency believes that the back door

ejection problem warrants immediate attention. Compliance should not

present any significant problems since the manufacturers are familiar

with the design changes needed, as they apply to back door latches to

meet Standard No. 206's current requirements.

Given the differences between side doors and back doors, NHTSA

believes that some minor modifications in Standard No. 206's test

requirements and procedures are needed for back doors. Of particular

note are the differences in the orientation of hinges and latches in

relation to the vehicle and in the variety of designs.

The difference in orientation is significant because the

requirements and procedures specified for longitudinal loading of

latches and hinges differ from those specified for transverse loading

of those components. If all back doors were just like side doors except

for their location on the back of the vehicle, the longitudinal and

transverse directions of the loading would simply be reversed with

respect to the latches and hinges of back doors. However, all back

doors are not just like side doors, thus the establishment of

appropriate test requirements and procedures for these doors is

somewhat more complicated.

There is considerably greater variety in the design of rear doors

than side doors. Side doors almost always open to the side and most

have hinges on their front edges and latches on their rear edges. Rear

doors may open upward, downward or sideways, and have latches and

hinges on the top, bottom or side. Moreover, while side doors are

generally vertical, when viewed in a front or back view, rear doors may

be vertical or sloped (as in the case of many hatchbacks), when viewed

in a side view.

The agency notes that there are a number of different designs for

rear doors and for their installation. Four typical back doors used in

production vehicles are:

(1) Door opens upward, with latch (or striker) at the bottom center

of the door with a single striker (or latch) on the back floor panel or

door sill;

(2) Door opens sideways, with striker located at the center of the

back side frame and latch located at the side edge of the door (for

example, back doors of large station wagons);

(3) Split doors with top, usually glass, opening upward and bottom

tailgate opening downward, with striker at the bottom of the top glass

door and latches or rod/pin connectors at top and sides of the tailgate

(for example, back doors of sport utility vehicles); and

(4) Double cargo-type doors, a two-part door that latches to itself

with one latch located at the center between the doors (for example,

back doors of some passenger vans).

It is possible that other door designs, such as sliding back doors,

may be used in future production vehicles. Therefore, the agency must

also include the sliding back door in this rulemaking.

Given the wide variety of back door designs and latch and hinge

orientations, NHTSA believes it is desirable to specify back door load

test requirements in terms of the latch and hinge rather than in terms

of longitudinal and transverse vehicle orientation. In addition, given

the nature of the loading that back door latches and hinges are likely

to experience in the event of a side impact to the rear quarter panel

of a vehicle, NHTSA believes it is appropriate to require latches and

hinges on doors that open upward to meet load requirements in three

rather than two directions.

B. Door Latches

1. Requirements for Secondary Latch Position

Standard No. 206 requires, for hinged side doors other than cargo-

type doors, that each door latch and striker assembly must be provided

with a fully latched position and a secondary latched position. Load

tests are specified for each position. As previously indicated, the

secondary position serves as a backup to the primary latched position

in the event the primary is not properly engaged and adds an additional

level of protection in case the primary latch position fails. The

requirement for a secondary latch position does not apply to hinged

cargo-type doors or sliding doors.

As part of proposing to extend Standard No. 206 to back doors,

NHTSA is considering applying the requirement for a secondary latch

position to some or all back doors. The agency requests comments on

which types of back doors should be included/excluded from this

requirement and why.

2. Load Requirements

Standard No. 206 specifies three load requirements for hinged side

doors: longitudinal load, transverse load, and inertia load. The

standard specifies differing load requirements for the fully latched

and secondary latched positions.

a. Load Test One. SAE J839 indicates that the purpose of the

longitudinal load test for side doors is to determine the ability of

the vehicle latch and striker to withstand a test load perpendicular to

the face of the latch. The test procedure states that the specified

load (11,000 Newtons (2,500 pounds) when in the fully latched position

and 4,450 Newtons (1,000 pounds) when in the secondary latched

position) is applied perpendicular to the face of the latch. NHTSA is

proposing to apply the same basic test requirement and procedure to

back doors. For back doors, however, the agency is proposing to use the

term ``Load Test One'' for this requirement, instead of ``longitudinal

load,'' since the latter term would be inappropriate given the

orientation of most back door latches.

b. Load Test Two. SAE J839 indicates that the purpose of the

transverse load test for side doors is to determine the ability of the

vehicle latch and striker to withstand the test load in the direction

of door opening. The test procedure states that the specified load

(8,900 Newtons (2,000 pounds) when in the fully latched position and

4,450 Newtons (1,000 pounds) when in the secondary latched position) is

applied in the direction of the door opening.

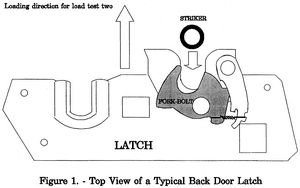

The agency is proposing to apply a corresponding test requirement/

procedure to back doors. To ensure that this second load test

requirement is not redundant and that latches can meet load

requirements in various directions (as may occur in real world

crashes), the agency is specifying that the load for this test is

applied in the direction of the fork-bolt opening and parallel to the

plane of the latch face. A depiction of the fork-bolt and the loading

direction is given in Figure 1. For most latches, this will be in the

same direction as the door opening. The agency is proposing to specify

the term ``Load Test Two'' for this test requirement.

c. Load Test Three. As indicated above, given the nature of the

loading that back door latches and hinges are likely to experience in

the event of a side impact to the rear quarter panel of a vehicle,

NHTSA believes it is appropriate to require latches on doors that open

upward to meet load requirements in three rather than two directions,

i.e., directions that correspond to the longitudinal and transverse

directions for side doors, and a third direction that is orthogonal to

the other two directions. The agency is therefore proposing a third

load test requirement in which a load would be applied in a direction

orthogonal to the directions specified in Load Tests One and Two (i.e.,

perpendicular to both of those directions). The test set-up for Load

Tests Two and Three is identical. However, the latch in Load Test Three

is mounted in a position perpendicular to that in Load Tests One and

Two.

NHTSA notes that, as indicated above, Standard No. 206 specifies,

for the fully latched position, an 11,000 Newton (2,500 pound) load for

the longitudinal load test and an 8,900 Newton (2,000 pound) load for

the transverse load test. In proposing to extend the requirements to

back doors, the agency is proposing the same loads as for the

corresponding Load Tests One and Two. The agency is considering whether

an 11,000 Newton (2,500 pound) load or an 8,900 Newton (2,000 pound)

load should apply to Load Test Three and requests comments on this

issue.

d. Inertia Load. Standard No. 206 requires that a side door latch

not disengage from the fully latched position when a longitudinal or

transverse inertia load of 30g is applied to the door latch system.

While the standard's procedures for the other load requirements specify

actual loading of a door latch in a test, mathematical analysis is

specified for the inertia load requirement. The agency notes that while

Standard No. 206 only specifies that the inertia load requirement must

be met for longitudinal and transverse loads, SAE 839b recommends that

the 30g requirement be met ``in any direction.'' The agency believes

that this requirement should be met by back doors in any direction,

since many latch orientations are possible for back doors. NHTSA

believes that this would best ensure adequate latch performance in the

many loading conditions experienced during real world crashes. The

agency specifically requests comments on the appropriateness of

requiring latches to meet the inertia load requirement in any

direction, as opposed to a limited number of directions, such as those

specified for Load Tests One, Two and Three.

C. Door Hinges

Standard No. 206 specifies that door hinges must support the door

and may not separate when a longitudinal load of 11,000 Newtons (2,500

pounds), or a transverse load of 8,900 Newtons (2,000 pounds), is

applied. The same considerations concerning longitudinal and transverse

loads discussed above with respect to latches apply to rear door

hinges. Therefore, the agency is proposing to specify the following

three load tests: Load Test One--load is applied in the direction

perpendicular to the hinge face plate; Load Test Two--load is applied

in the direction perpendicular to the axis of the hinge pin and

parallel to the hinge face plate; Load Test Three--load is applied in

the direction of the axis of the hinge pin. The third test is proposed

for hinges on doors that open upward. The agency is considering whether

an 11,000 Newton (2,500 pound) load or an 8,900 Newton (2,000 pound)

load should be specified for these three tests and requests comments on

this issue.

D. Door Locks

Standard No. 206 specifies that side doors must be equipped with a

locking mechanism with an operating means in the interior of the

vehicle. For locks in side front doors, the outside door handle must be

inoperative when the locking mechanism is engaged. For side rear door

locks, both the outside and inside door handles must be inoperative

when the locking mechanism is engaged.

The agency recognizes that many production vehicles do not have a

true ``locking mechanism'' on their back doors and provide no inside

door handles. In many cases, unlatching can not be performed by

occupants seated near such doors. As part of proposing to extend

Standard No. 206 to back doors, NHTSA is considering applying door lock

requirements to some or all back doors. The agency requests comments on

whether the requirements for side front door locks or side rear door

locks should be extended to back doors, which types of back doors

should be included/excluded from this requirement, and why.

E. Leadtime

The agency is proposing an effective date of the first September 1

that occurs following a two year period beginning with publication of a

final rule. NHTSA believes that a leadtime of about two years is

needed, since manufacturers will need to make design and tooling

changes for many of their passenger cars and MPVs. The agency believes

that a longer leadtime would be unnecessary, since manufacturers are

already familiar with the kinds of designs needed to comply with the

requirements of Standard No. 206.

F. Additional Considerations and Questions

Given the wide variety of passenger car and MPV designs, both with

respect to the back door latch itself and with respect to passenger

access to the back door, NHTSA recognizes that there may be a number of

issues concerning whether some of the proposed requirements should

apply to only certain back doors and whether any additional

modifications need to be made in the test requirements and procedures

to make them appropriate for all covered vehicles. The agency

specifically requests comments on the following questions:

1. As discussed above, the full requirements of Standard No. 206

apply only to hinged side doors other than cargo-type doors;

abbreviated requirements apply to hinged cargo-type doors and to

sliding doors. To what extent should full versus abbreviated

requirements apply to back doors? Are there any back doors, such as

split back doors, to which the requirements should not apply at all?

2. Are the proposed test requirements adequately clear and

appropriate for all back doors? For example, are latch faces and hinge

faces designed so that the direction perpendicular to these components

can readily be determined? Commenters who believe that some of proposed

requirements are not adequately clear are encouraged to suggest

specific changes to clarify the procedures. Depending on the comments,

the agency may make changes in the procedures in a final rule.

3. Identify which and how many of your current passenger car

hatchbacks, station wagons, sport utility vehicles, and vans would need

to be upgraded to meet the proposed requirements for: (a) latching

mechanisms; (b) hinges, and (c) locks? Please indicate the consumer

cost to upgrade and the relative increase in strength or other benefit

for each upgrade.

4. Identify which and how many of your current passenger car

hatchbacks, station wagons, sport utility vehicles, and vans would pass

the proposed requirements for: (a) latching mechanisms, (b) hinges, and

(c) locks?

5. Please identify and/or provide any studies or data that might

assist the agency in quantifying the safety or other benefits of this

proposed rulemaking action.

III. Costs and Benefits

The proposed amendments to Standard No. 206 would affect back door

locks and door retention components on passenger car hatchbacks,

station wagons, utility vehicles, and vans. About 1.5 million

hatchbacks, 0.4 million station wagons, 1.6 million utility vehicles,

and 1.8 million vans are expected to be produced in the 1997 model

year, for a total of about 5.3 million vehicles that would potentially

be affected by the proposed amendments in this notice, if they are

required on a proposed effective date before September 1, 1997.

In an evaluation of back door latches in minivans (docket No. 94-

70-N01), the agency conducted repeat tests of 8 latches from different

minivans in accordance with the testing procedures of Standard No. 206.

Those 8 latches represented vehicle sales of about 1 million vehicles

in 1993. One of the tested latches failed the proposed Load Test Two

requirement and another failed the proposed Load Test One requirement.

All the others exceeded those load requirements, some passing by a

margin of 125 percent in the Load Test Two direction and 90 percent in

the Load Test One direction. The 6 complying latches represent about 50

percent (0.5 million) of the 1993 minivan sales. It is reasonable to

conclude, therefore, that approximately half of the minivan fleet

already meets or exceeds the requirements proposed in this notice.

NHTSA has not tested the back door latch mechanisms of hatchbacks,

station wagons and utility vehicles. Given the data obtained from the

minivan tests, however, and considering that most of the 1.6 million

sport utility vehicles have back door latch systems that are similar to

those on minivans, the agency believes that about 50 percent (0.8

million) of sport utility vehicles would also meet the requirements

proposed in this notice. Although many additional vehicles may also

comply, the agency has conservatively assumed that all of the vehicles

other than half the minivan and half the sport utility vehicle fleets

may require some modification to meet the proposed requirements. That

leaves the total number of affected vehicles at approximately 4.0

million. Although those vehicles could require some upgrading of their

current back door locks and door retention components, these proposed

amendments are expected to require not more than 1 or 2 minor to

moderate changes in either latching, hinge, or locking mechanisms.

In evaluating the costs of the 8 minivan latches tested, the agency

compared the production costs of a failing latch and a passing latch,

which were $3.87 and $2.81 respectively. Thus, the cost of the superior

latch was about $1.00 less than that of the failing latch. The agency

also examined the retail costs of the 8 latches tested, which ranged

from $22.03 to $81.74. The costs of the 2 failing latches were $23.52

and $63.19. The tests demonstrated, therefore, that a latch that meets

the requirements of Standard No. 206 need not be more expensive than

one that does not. Other factors, such as design features and materials

used, could significantly affect the costs of latches. Given the

assumption that no more than 4.0 million vehicles may require upgrades

because of the proposed requirements of this notice, and that the cost

of an upgrade is not necessarily higher than the cost of current

designs, NHTSA has concluded that the cost of extending the current

requirements of Standard No. 206 to back doors would be minimal.

Proposed compliance tests for back door locks and door retention

components typically would be conducted with similar but at times

slightly modified test equipment of the type that is currently used to

evaluate side door locks and retention components. Thus, no significant

test equipment costs should be incurred by manufacturers. Compliance

testing costs should also be similar to that for side doors, about

$110.

Currently, about 147 deaths and 740 injuries occur each year that

involve occupant ejection through back doors. The amendments proposed

in this notice should provide some benefits in reducing these deaths

and injuries since over 80 percent of these ejection accidents involve

hinge or latch damage and these components would be upgraded. However,

at this time, the agency is not able to quantify these benefits or

costs with sufficient precision to determine the cost effectiveness of

this proposed rulemaking action. In this notice, the agency is seeking

data and comments that should allow more precise estimates to be made.

IV. Rulemaking Analyses and Notices

A. E.O. 12866 and DOT Regulatory Policies and Procedures

This notice has not been reviewed under EO 12866, ``Regulatory

Planning and Review.'' The agency has considered the impact of this

rulemaking action and has concluded that it is not ``significant''

under the DOT's Regulatory Policies and Procedures. Since the

amendments in this notice are primarily an extension of the present

passenger vehicle side door latch, hinge, and lock requirements to

include the back doors of passenger motor vehicles with a GVWR of 4,536

kg (10,000 lb) or less, the agency believes that any necessary minor to

moderate hardware changes can be readily incorporated into back door

designs within the leadtime provided, with very little or no economic

impact. Given the lack of significant industry impact and minor

economic significance of this rulemaking, a Preliminary Regulator

Evaluation is not considered necessary and has not been prepared.

B. Regulatory Flexibility Act

NHTSA has considered the impacts of this rulemaking action under

the Regulatory Flexibility Act. I hereby certify that the proposed

amendments would not have a significant economic impact on a

substantial number of small entities. Accordingly, the agency has not

prepared a preliminary regulatory flexibility analysis.

The agency believes that few, if any, motor vehicle manufacturers

qualify as small businesses. Therefore, small businesses, small

organizations, and small governmental units would be affected by this

rulemaking only to the extent that they may pay very slightly more for

the vehicles that they purchase with the qualifying back door latches

and hinges.

C. National Environmental Policy Act

NHTSA has analyzed this rulemaking action for purposes of the

National Environmental Policy Act and has determined that

implementation of this action would have no significant impact on the

quality of the human environment.

D. E.O. 12612, Federalism

NHTSA has analyzed this proposal in accordance with the principles

and criteria contained in E.O. 12612 and has determined that the

proposals in this notice do not have sufficient federalism implications

to warrant preparation of a Federalism Assessment. No state laws would

be affected.

E. Civil Justice Reform

These proposed amendments would not have any retroactive effect.

Under 49 U.S.C. 30103(b), whenever a Federal motor vehicle safety

standard is in effect, a state or political subdivision of a state may

prescribe or continue in effect a standard applicable to the same

aspect of performance of a motor vehicle only if the standard is

identical to the Federal standard. However, the United States

Government, a state or political subdivision of a state may prescribe a

standard for a motor vehicle or motor vehicle equipment obtained for

its own use that imposes a higher performance requirement than that

required by the Federal standard. 49 U.S.C. 30161 sets forth a

procedure for judicial review of final rules establishing, amending or

revoking Federal motor vehicle safety standards. A petition for

reconsideration or other administrative proceedings is not required

before parties may file suit in court.

V. Comments

Interested persons are invited to submit comments on the amendments

proposed in this rulemaking action. It is requested but not required

that any comments be submitted in 10 copies each.

Comments must not exceed 15 pages in length (49 CFR 553.21). This

limitation is intended to encourage commenters to detail their primary

arguments in concise fashion. Necessary attachments, however, may be

appended to those comments without regard to the 15-page limit.

If a commenter wishes to submit certain information under a claim

of confidentiality, 3 copies of the complete submission including the

purportedly confidential business information, should be submitted to

the Chief Counsel, NHTSA at the street address shown above, and 7

copies from which the purportedly confidential information has been

deleted should be submitted to the Docket Section. A request for

confidentiality should be accompanied by a cover letter setting forth

the information specified in 49 CFR 512, the agency's confidential

business information regulation.

All comments received on or before the close of business on the

comment closing date indicated above for the proposal will be

considered, and will be available to the public for examination in the

docket at the above address both before and after the closing date. To

the extent possible, comments received after the closing date will be

considered. Comments received too late for consideration in regard to

the final rule will be considered as suggestions for further rulemaking

action. Comments on the proposal will be available for public

inspection in the docket. NHTSA will continue to file relevant

information in the docket after the closing date, and it is recommended

that interested persons continue to monitor the docket for new

material.

Those persons desiring to be notified upon receipt of their

comments in the rules docket should enclose a self-addressed stamped

postcard in the envelope with their comments. Upon receiving the

comments the docket supervisor will return the postcard by mail.

List of Subjects in 49 CFR Part 571

Imports, Motor vehicle safety, Motor vehicles, Rubber and rubber

products, and Tires.

In consideration of the foregoing, 49 CFR part 571 would be amended

as follows:

PART 571--FEDERAL MOTOR VEHICLE SAFETY STANDARDS

1. The authority citation for Part 571 would read as follows:

Authority: 49 U.S.C. 30111, 30115, 30117, and 30166; delegation

of authority at 49 CFR 1.50.

2. Section 571.206 would be amended by revising S1 and S2, adding 3

definitions to S3 in alphabetical order, revising S4 and the headings

of S4.1, S4.2, and S4.3, adding S4.4 through S4.5, revising the

headings of S5.1, S5.2 and S5.3, and adding S5.4 through S5.5 and

Figure 1, to read as follows:

Sec. 571.206 Standard No. 206; Door locks and door retention

components.

S1. Purpose and Scope. This standard specifies requirements for

door locks and door retention components including latches, hinges, and

other supporting means, to minimize the likelihood of occupants being

thrown from the vehicle as a result of impact.

S2. Application. This standard applies to passenger cars,

multipurpose passenger vehicles, and trucks.

S3. Definitions. Back door means a door or door system on the back

end of a vehicle through which passengers can enter or depart the

vehicle, or cargo can be loaded or unloaded.

Fork-bolt means the part of the door latch that engages the striker

when in a latched position.

Fork-bolt opening means the direction opposite to that in which the

striker enters to engage the fork-bolt.

* * * * *

S4. Requirements. Components on any side door leading directly into

a compartment that contains one or more seating accommodations, and

components on any back door of a passenger car or multipurpose

passenger vehicle with a gross vehicle weight rating of less than 4,536

kilograms (10,000 pounds), shall conform to this standard. However,

components on folding doors, roll-up doors, doors that are designed to

be easily attached to or removed from motor vehicles manufactured for

operation without doors, and doors which are equipped with wheelchair

lifts and which are linked to an alarm system consisting of either a

flashing visible signal located in the driver's compartment or an alarm

audible to the driver which is activated when the door is open, need

not conform to this standard.

S4.1. Hinged Side Doors, Except Cargo-Type Doors.

* * * * *

S4.2. Hinged Cargo-Type Side Doors.

* * * * *

S4.3. Sliding Side Doors.

* * * * *

S4.4. Hinged Back Doors.

S4.4.1. Door Latches. Each door latch and striker assembly shall be

provided with two positions consisting of--

(a) A fully latched position; and

(b) A secondary latched position.

S4.4.1.1 Load Test One. The door latch and striker assembly, when

in the fully latched position, shall not separate when a load of 11,000

Newtons (2,500 pounds) is applied in the direction perpendicular to the

face of the latch such that the latch and the striker anchorage are not

compressed against each other. When in the secondary locked position,

the door latch and striker assembly shall not separate when a load of

4,450 Newtons (1,000 pounds) is applied in the same direction.

S4.4.1.2 Load Test Two. The door latch and striker assembly, when

in the fully latched position, shall not separate when a load of 8,900

Newtons (2,000 pounds) is applied in the direction of the fork-bolt

opening and parallel to the face of the latch. Figure 1 depicts the

loading direction for this test. When in the secondary latched

position, the door latch and striker assembly shall not separate when a

load of 4,450 Newtons (1,000 pounds) is applied in the same direction.

S4.4.1.3 Load Test Three. The door latch on doors that open upward

shall not disengage from the fully latched position when a load of

8,900 Newtons (2,000 pounds) is applied in a direction orthogonal to

the directions specified in S4.4.1.1 and S4.4.1.2 above.

S4.4.1.4 Inertia load. The door latch shall not disengage from the

fully latched position when an inertia load of 30g is applied to the

door latch system (including the latch and its actuating mechanism with

the locking mechanism disengaged) in any direction.

S4.4.2 Door Locks. Each door shall be equipped with a locking

mechanism with an operating means in the interior of the vehicle. When

the locking mechanism is engaged, both the outside and inside door

handles or other latch release controls shall be inoperative.

S4.4.3 Door Hinges.

S4.4.3.1 Load Test One. Each door hinge system shall support the

door and shall not separate when a load of 11,000 Newtons (2,500

pounds) is applied perpendicular to the hinge face plate such that the

hinge plates are not compressed against each other.

S4.4.3.2 Load Test Two. Each door hinge system shall not separate

when a load of 8,900 Newtons (2,000 pounds) is applied perpendicular to

the axis of the hinge pin and parallel to the hinge face plate such

that the hinge plates are not compressed against each other.

S4.4.3.3 Load Test Three. Each door hinge on doors that open upward

shall not separate when a load of 8,900 Newtons (2,000 pounds) is

applied in the direction of the axis of the hinge pin.

S4.5 Sliding Back Doors. The track and slide combination or other

supporting means for each sliding door shall not separate when a total

longitudinal load of 17,800 Newtons (4,000 pounds) is applied, with the

door in the closed position.

* * * * *

S5.1 Hinged Side Doors, Except Cargo-Type Doors.

* * * * *

S5.2 Hinged Side Cargo-Type Doors.

* * * * *

S5.3 Sliding Side Doors.

* * * * *

S5.4 Hinged Back Doors.

S5.4.1 Door Latches.

S5.4.1.1 Load Tests One, Two and Three. Compliance with S4.4.1.1,

S4.4.1.2, and S4.4.1.3 shall be demonstrated in the same manner as

specified in S5.1.1.1, except that the loads shall be in the directions

specified in S4.4.1.1, S4.4.1.2, and S4.4.1.3.

S5.4.1.2 Inertia Load. Compliance with S4.4.1.4 shall be

demonstrated in the same manner as specified in S5.1.1.2.

S5.4.2 Door Hinges. Compliance with S4.4.3.1, S4.4.3.2 and S4.4.3.3

shall be demonstrated in the same manner as specified in S5.1.2, except

that the loads shall be in the directions specified in S4.4.3.1,

S4.4.3.2, and S4.4.3.3.

S5.5 Sliding Back Doors. Compliance with S4.5 shall be demonstrated

by applying an outward longitudinal load of 8,900 Newtons (2,000

pounds) to the load bearing members at the opposite edges of the door

(17,800 Newtons (4,000 pounds) total). The demonstration may be

performed either in the vehicle or with the door retention components

in a bench test fixture.

BILLING CODE 4910-59-P

Barry Felrice,

Associate Administrator for Rulemaking.

BILLING CODE 4910-59-C

[FR Doc. 94-21384 Filed 8-29-94; 8:45 am]

BILLING CODE 4910-59-P

Barry Felrice,

Associate Administrator for Rulemaking.

BILLING CODE 4910-59-C

[FR Doc. 94-21384 Filed 8-29-94; 8:45 am]

BILLING CODE 4910-59-P