Control of Air Pollution From New Motor Vehicles and New Motor Vehicle Engines; Refueling Emission Regulations for Light-Duty Vehicles and Light-Duty Trucks; Final Rule |

|---|

|

Carol M. Browner

Environmental Protection Agency

April 6, 1994

[Federal Register: April 6, 1994]

_______________________________________________________________________

Part II

Environmental Protection Agency

_______________________________________________________________________

40 CFR Parts 86, 88, and 200

Control of Air Pollution From New Motor Vehicles and New Motor Vehicle

Engines; Refueling Emission Regulations for Light-Duty Vehicles and

Light-Duty Trucks; Final Rule

ENVIRONMENTAL PROTECTION AGENCY

40 CFR Parts 86, 88, and 600

[AMS-FRL-4831-6]

RIN 2060-AC64

Control of Air Pollution From New Motor Vehicles and New Motor

Vehicle Engines; Refueling Emission Regulations for Light-Duty Vehicles

and Light-Duty Trucks

AGENCY: Environmental Protection Agency (EPA).

ACTION: Final rule.

-----------------------------------------------------------------------

SUMMARY: This document contains EPA's final rule implementing the

control of vehicle refueling emissions through the use of vehicle-based

systems. It applies to light-duty vehicles and light-duty trucks. The

rule applies to all fuels used by a vehicle, and includes special

provisions for vehicles/fuels judged to be inherently low in refueling

emissions. For light-duty vehicles, the requirements begin in the 1998

model year, and phase in over three model years. In the 1998 model

year, 40 percent of each manufacturer's light-duty vehicles must meet

the requirements. This increases to 80 percent in the 1999 model year

and rises to 100 percent in model years 2000 and later. A special

provision for phase-in is also included for small volume manufacturers

of light-duty vehicles.

This requirement also applies to light-duty trucks. For light-duty

trucks with a gross vehicle weight rating of 0-6000 lbs, the

requirement begins in model year 2001 and phases-in over three model

years at the same rate as applied to light-duty vehicles. For light-

duty trucks with a gross vehicle weight rating of 6001-8500 lbs, the

requirement commences in model year 2004 and phases-in over three model

years at the same rate as light-duty vehicles. The rule does not apply

to heavy-duty vehicles.

This rule also establishes certification requirements covering test

procedures for integrated and non-integrated control system designs, a

refueling emission standard of 0.20 g/gallon and other related

certification requirements and provisions. Finally, the rule contains

enforcement provisions related to liability, Selective Enforcement

Auditing and nonconformance penalties.

EFFECTIVE DATES: This final rule is effective on May 6, 1994.

The new information collection requirements contained in 40 CFR

parts 86 and 88 applying to 1998 and later model year vehicles have not

been approved by the Office of Management and Budget (OMB) and are not

effective until OMB has approved them. EPA will publish a technical

amendment in the Federal Register once the information collection

requirements are approved.

ADDRESSES: Materials relevant to this final rule are contained in

Public Docket No. A-87-11, located in the Air and Radiation Docket and

Information Center of the U.S. Environmental Protection Agency, 401 M

Street SW., Washington, DC, 20460 and is available for public review in

room M-1500. Relevant materials may also be found in Public Docket No.

A-84-07, established in support of EPA's assessment of air pollution

regulatory strategies for the gasoline marketing industry. The dockets

may be inspected from 8 a.m. to 4 p.m. Monday through Friday, except

for government holidays. Under 40 CFR part 2, a reasonable fee may be

charged by EPA for copying docket materials.

FOR FURTHER INFORMATION CONTACT: James G. Bryson, U.S. EPA (RDSD-12),

Special Regulatory Projects Branch, 2565 Plymouth Road, Ann Arbor, MI

48105, Telephone: (313) 741-7828.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Background

II. Description of the Rule

A. Applicability

1. Application of the Refueling Emission Standard to LDVs

2. Extension of the ORVR Requirement to LDTs

3. Heavy Duty Vehicles

4. Applicability to California Vehicles

5. Fuels Covered

B. Implementation

1. Leadtime, Effective Model Year and Phase-in Requirements

2. Small Volume Manufacturers

3. Inclusion of Inherently Low Refueling Emission Vehicles

C. Refueling Emission Test Procedures and Standard

1. Refueling Emissions Test

2. Integrated System Preconditioning

3. Non-Integrated System Preconditioning

4. Seal Test

5. Cap Removal Emissions

6. Spitback Test

7. Nozzle Geometry Standards

8. Level of the Standard

D. Safety of ORVR Systems

1. Background

2. Test Procedure/Safety

3. DOT Consultation

4. EPA Assessment

5. Safety Reviews

6. Alternative Control Technologies

E. Certification Provisions

1. General

2. Fees

3. Fuel Economy

F. Onboard Diagnostics Requirements

G. Enforcement and In-Use Performance

1. Liability Periods

2. Selective Enforcement Audit Testing

3. Nonconformance Penalties (NCPs)

4. In-Use Performance

III. Public Participation

IV. Regulatory Impact Analysis

A. Environmental Impact

B. Costs of Control

C. Cost Effectiveness

D. Other Benefits

E. Benefit-Cost Ratio

V. Consultation with DOT

VI. Judicial Review

VII. Statutory Authority

VIII. Executive Order 12866

IX. Compliance With the Regulatory Flexibility Act

X. Information Collection Requirements

List of Key Acronyms

AA Attainment Area

AAMA American Automobile Manufacturers Association

AIAM Association of International Automobile Manufacturers

CAA Clean Air Act

CAAA CAA Amendments

DoT Department of Transportation

FMVSS Federal Motor Vehicle Safety Standards

GVWR Gross Vehicle Weight Rating

HDV Heavy-Duty Vehicle

LDV Light-Duty Vehicle

LDT Light-Duty Truck

LLDT Light LDT

HLDT Heavy LDT

NAA Non-Attainment Area

NCP Nonconformance Penalty

NHTSA National Highway Traffic Safety Administration

NPV Net Present Value

ORVR Onboard Refueling Vapor Recovery

RIA Regulatory Impact Analysis

RPE Retail Price Equivalent

RVP Reid Vapor Pressure

VOC Volatile Organic Compounds

I. Background

On August 19, 1987, EPA published in the Federal Register a Notice

of Proposed Rulemaking (NPRM) for the control of vehicle refueling

emissions (52 FR 31162). The proposal described the need for these

controls as well as the conclusions of an EPA study of gasoline

marketing emissions comparing the relative merits of the two available

control technologies: Systems incorporated into the gasoline dispensing

pump system design (known as Stage II vapor recovery) and systems

incorporated into the design of the vehicle (known as onboard refueling

vapor recovery (ORVR)) (see Public Docket A-84-07). Based on this

study, along with EPA's analysis and response to public comments

published in documents separate from the NPRM (Evaluation of Air

Pollution Regulatory Strategies for Gasoline Marketing Industry--

Response to Public Comments (II-A-20), Draft Regulatory Impact

Analysis: Proposed Refueling Emission Regulations for Gasoline-Fueled

Motor Vehicles, Vols. I and II) (II-A-18, 19), and technical support

documents related to ORVR test procedure (II-A-08) and ORVR vehicle

safety (II-A-17), EPA proposed to require refueling emission control

through ORVR systems. The above mentioned studies are available in

public docket A-87-11. All future references of this nature can be

found at the cited location in public docket A-87-11 unless otherwise

indicated.

Subsequent to the publication of the NPRM, EPA held a public

hearing in October 1987, followed by an extensive public comment period

which closed in February 1988. Comments were analyzed by EPA and key

issues were assessed. As a result, EPA determined that the final

rulemaking should be delayed pending the resolution of safety concerns

expressed by both the National Highway Traffic Safety Administration

(NHTSA) (part of the Department of Transportation (DoT)) and a number

of the commenters. The final rule was further delayed when it became

evident that Congress would address issues concerning refueling

controls in the 1990 Clean Air Act Amendments (CAAA).

The 1990 Amendments revised section 202(a)(6) of the CAA to read as

follows:

Within 1 year after the date of the enactment of the Clean Air

Act Amendments of 1990, the Administrator shall, after consultation

with the Secretary of Transportation regarding the safety of

vehicle-based (`onboard') systems for the control of vehicle

refueling emissions, promulgate standards under this section

requiring that new light-duty vehicles manufactured beginning in the

fourth model year after the model year in which the standards are

promulgated and thereafter shall be equipped with such systems.

Subsequent to the enactment of the CAAA, EPA continued its

consultation with DOT/NHTSA related to the potential safety concerns

regarding the implementation of vehicle-based refueling emission

controls. In July 1991, NHTSA completed an updated safety study

entitled ``An Assessment of the Safety on Onboard Refueling Vapor

Recovery Systems''. On September 3, 1991, EPA published an additional

Federal Register notice (56 FR 43682) releasing the NHTSA report for

public review and seeking further comment on key issues involved with

ORVR controls, most notably on circumstances that had changed since the

publication of the NPRM. The notice also described and sought comment

on a document entitled ``Summary of Changed Circumstances'', which

discussed statutory changes, technology development, and potential

modifications to the refueling test procedure.

EPA held a public hearing on September 26 and 27, 1991, and public

comments were received for 30 days thereafter. After reviewing these

comments, EPA continued its consultation with NHTSA. Based on the

outcome of the consultation, EPA determined that ORVR controls should

not be required at that time. The Agency took this step because it

concluded, after consultation with NHTSA and after considering the

conclusions of NHTSA's safety study, that ORVR controls posed

``unreasonable'' safety risks relative to Stage II systems. A Federal

Register notice detailing the decision and the supporting rationale was

published on April 15, 1992 (57 FR 13220).

EPA's action was challenged by representatives of the petroleum

refining, gasoline marketing, environmental and consumer auto safety

communities. They argued that section 202(a)(6) of the CAA created a

non-discretionary duty to promulgate ORVR standards for LDVs. The court

agreed, holding that EPA had no choice but to promulgate such

standards, and that the entire safety analysis in the April 15, 1992

notice was flawed because of the comparison with Stage II technology, a

comparison not allowed by the text of the statute. NRDC v. EPA, 983 F.

2d 259, 261, 269-71 (D.C. Cir. 1993). The court stated further, in

dicta, that the record did not establish that all ORVR systems present

inherent and unreasonable safety risks. Id. at 261, 270. The court set

aside the April 15, 1992 Agency action, and ordered EPA to promulgate

regulations requiring vehicle-based refueling controls on LDVs in

accordance with the CAA.

The petitioners further moved the court for an order requiring EPA

to issue ORVR requirements by a particular date. Before the court

ruled, EPA and the petitioners entered into a settlement agreement

whereby the Agency agreed to promulgate such rules by January 22, 1994

(58 FR 33813, June 21, 1993).

Subsequent to the court's decision, EPA published two Federal

Register notices (May 27, 1993, 58 FR 30731 and June 17, 1993, 58 FR

33418) seeking public comment on the key issues that had changed since

the last public comment period. EPA also held a public hearing on these

issues on July 22, 1993, and solicited comments for 30 days thereafter.

EPA has analyzed these additional comments, and has revised its

proposed regulations accordingly. To support this rule, two key

documents, a Final Regulatory Impact Analysis and a Summary and

Analysis of Comments have been completed and are available for review

in the public docket.

The remainder of the document is divided into sections. Section II

describes the various aspects of the rule as listed in the Table of

Contents above, and provides rationale for the approaches being

implemented. Section III describes the long and extended public

participation in the rulemaking process and previous study. Section IV

summarizes the Regulatory Impact Analysis. Finally, sections V through

X describe various aspects of the rule with regard to compliance with

various administrative requirements such as the Regulatory Flexibility

Act and the Paperwork Reduction Act.

II. Description of the Rule

A. Applicability

1. Application of the Refueling Emission Standard to LDVs

Section 202(a)(6) of the Act mandates that EPA promulgate

requirements for new light-duty vehicles (LDVs) to be equipped with

ORVR systems. In the August 1987 NPRM, EPA proposed that ORVR

requirements apply to LDVs and, in this rule, is finalizing that LDV

portion of the original NPRM, consistent with the statutory

requirements. The model year, phase-in, certification and other

requirements for LDVs are discussed in sections B through F, below.

2. Extension of the ORVR Requirement to LDTs

Under the authority provided in Section 202(a)(1) of the Clean Air

Act (CAA), EPA is applying the ORVR requirement to light-duty trucks

(LDTs). EPA is finalizing portions of that proposal in today's rules.

Each manufacturer's LDTs will have to meet the refueling emission

requirements under the phase-in schedule and compliance program for

trucks described in the Implementation section below.

In reaching this decision, EPA has conducted a detailed analysis of

the need for and desirability of extending the requirement beyond the

LDV class. The analysis is detailed in the supporting Regulatory Impact

Analysis (RIA) available in the public docket. The key points are

summarized below.

First, the rule affects pollutants which ``cause or contribute to

air pollution which may reasonably be anticipated to endanger public

health or welfare'' (Section 202(a)(1)). Hydrocarbons, as ozone

precursors, have long been an essential object of emission control

strategies (both vehicles and non-vehicles). Ambient ozone is an

irritant that adversely affects pulmonary membranes, lung tissues, and

lung functions, and is also associated with adverse ecological effects.

Refueling emissions also contain benzene, a Group A human carcinogen.

The gasoline vapors themselves also adversely affect public health and

welfare.

Second, and perhaps most compelling, is the large amount of

refueling emissions which arise from these LDTs. In 1990, trucks

represented about 33 percent of the gasoline used by highway motor

vehicles. Using American Automobile Manufacturers Association (AAMA)

figures, retail truck sales have increased at a compound annual rate of

4-5 percent over the past ten years, and this growth is projected to

continue well into the next century. This increase in sales and market

fraction has led to an increase in the gasoline used by trucks. The

fraction of gasoline used by LDTs is projected to increase to 37

percent by 2000 and continue at that level or higher in the future.

Thus, the percentage of the refueling emissions inventory attributable

to LDTs is large and is expected to increase in the future.

Another way to look at the magnitude of the emissions from LDTs is

the equivalent gram per mile (g/mi) emission rate attributable to their

uncontrolled refueling emissions. As shown in the RIA, taking into

account Phase II RVP control and the RVP effects of reformulated

gasoline, the nationwide uncontrolled refueling emission rate during

the ozone season for LDTs is about 0.22 g/mi. These are large emission

rates in contrast to those controlled by other strategies being

implemented under the 1990 CAAA and being considered by the states in

their State Implementation Plans. A good example is the Clean-Fuel

Fleet requirements under section 246 of the CAA and the Low Emission

Vehicle program being implemented in California and perhaps in other

states. In these cases the equivalent emission reductions are in the

range of 0.12 to 0.18 g/mile.

Third, EPA believes that ORVR controls are technologically feasible

for LDTs. Reports and other materials submitted to the docket over the

past several years as well as comments by the regulated industry

indicate that prototype ORVR systems have been installed on a number of

passenger cars and light trucks (IV-A-06, IV-D-682, 680, 682, 685, 688,

864, 701, 712, 718, 719, 720, 721, IV-E-50, 73). As is now the case

with evaporative control systems, we anticipate that the control

technology used for LDT ORVR systems will be very similar to that

applied to LDVs. Although there are some differences between LDV and

LDT fuel systems (e.g., tank size in some larger LDTs), the general

fuel system concepts, designs, and configurations are very similar. In

addition, vehicles in both classes must meet the recently promulgated

enhanced evaporative emission control requirements beginning in the

1996 model year. As with LDVs, EPA anticipates that the same

evaporative emission control technology can be applied to control

refueling emissions in LDTs. To ensure that the enhanced evaporative

control system canister and purge system can be applied to ORVR

controls, EPA is applying the same refueling emission test procedure

approach to LDTs as is being applied to LDVs. The only significant

design difference will be the need for some form of a fillneck seal.

However, with the anticipated liquid seal approach this requires at

most a minor fillneck modification and does not involve new hardware.

While there are vehicle-to-vehicle differences in fuel system

designs, these affect both the evaporative and refueling emission rates

for a given vehicle/fuel system design. To EPA's knowledge there is

nothing unique about the design or function of LDT fuel systems

relative to LDVs which would suggest that the test procedure approach

being applied to LDVs would not be equally effective for LDTs in

accomplishing the goal of allowing the widespread use of integrated

enhanced evaporative/refueling emission control systems. Although

uncertainty has been expressed, no commenter provided data or even a

substantiated argument to support the view that the test procedure

modifications would not be equally effective in facilitating LDT use of

integrated enhanced evaporative/refueling control systems. In fact,

testing conducted by the Coordinating Research Council (CRC-APRAC

Project VE-6) (IV-D-565) and EPA (II-A-06) indicate no significant

difference between LDV and LDT uncontrolled refueling emission rates.

As is the case for LDVs, the refueling test procedure approach

described above should allow the widespread use of integrated

refueling/evaporative control systems for LDTs. Thus, since there is no

problem with applying enhanced evaporative control systems to LDTs,

there should be no problem with integrated evaporative/ refueling

control systems.

The benefits of applying the ORVR requirements to LDTs exceed the

costs of the requirement. Since EPA believes, and the manufacturers'

comments indicate, that most vehicles will use an integrated

evaporative/refueling control system, the incremental costs of LDT ORVR

controls are relatively small. As detailed in the RIA, EPA's cost is

comprised of added hardware (mostly an improved vent/rollover valve and

larger diameter vapor line) and short term development costs (for

emissions and safety certification, facility modification hardware/

tooling modifications, and systems engineering) minus the fuel recovery

credit. The size of the fuel recovery credit depends on the amount of

vapor captured. This in turn depends on the fuel used, the emissions

rate (g/gal), and the presence or absence of Stage II vapor recovery.

Taking all of these factors into account, and assuming Stage II

controls in most of the ozone NAAs, the cost estimate for LDTs/HDVs are

shown below in Table 1.

Table 1.--Estimated Per-Vehicle Costs of ORVR Systems in LDTs

----------------------------------------------------------------------------------------------------------------

Hardware ($/ Develop ($/ Operating cost Short term net Long term net

Vehicle group vehicle) vehicle) (NPV) cost cost

----------------------------------------------------------------------------------------------------------------

LDT.............. $4.79 $2.65 -$3.70 $3.74 $1.09

----------------------------------------------------------------------------------------------------------------

For vehicles operating in nonattainment areas (NAAs), the recovery

credits are smaller and the short and long term net costs increase by

about $3 per vehicle over those in the table above.

As was discussed above, LDTs represent over 33 percent of the

nation's gasoline consumption. With the test procedure and control

system approach mentioned above, EPA expects that the in-use control

efficiency of LDT ORVR systems will exceed 95 percent. Incremental to

Stage II controls, LDT ORVR controls would provide a nationwide average

annual emission reduction of 115,000 tons between 1998 and 2020.

Reductions in NAAs with Stage II controls are large as well. With no

Stage II phase-out, the average annual emission reduction in the NAAs

is 31,000 tons. If Stage II is phased out when ORVR is in widespread

use (2010), the average annual emission reduction in the NAAs

attributable to LDT controls increases to 68,000 tons. These

incremental reductions in NAAs are large relative to the other control

options available.

As is discussed below, reductions in refueling emissions have value

in all areas of the country. However, the main focus of the ORVR

requirement is to provide ozone NAAs additional reductions to assist

them in complying or maintaining compliance with the ozone standard.

Thus, the important areas to consider are those which are not now in

compliance with the ozone standard. At present there are 54 marginal or

worse ozone NA areas, which represent about 54.9 percent of the

nationwide highway gasoline consumption. Of these 54 areas, about 43

now have, or are expected to have, Stage II vapor recovery systems in

place. Since ORVR controls are required on all LDVs, and Stage II vapor

recovery is (or will be) in place in most moderate or worse ozone NAAs,

the key comparison to be made is (1) retaining Stage II controls in the

moderate or worse ozone NAAs solely for the purpose of controlling LDT/

HDV refueling emissions, versus (2) requiring ORVR controls for LDTs

and possibly HDVs, assuming the Stage II control that is or will be in

place. This comparison provides a worst case perspective on the LDT/HDV

cost effectiveness, since benefits outside NAAs are ignored and planned

Stage II is assumed to continue after the ORVR requirement is

promulgated.

As is described in the RIA, EPA has conducted the analysis for both

the Stage II retention and ORVR options. The cost effectiveness of

retaining Stage II solely for the purpose of controlling LDT/HDV

refueling emissions is about $3400 per ton. The cost effectiveness of

the LDT ORVR controls incremental to the Stage II now in place is about

$200 per ton if Stage II is phased out when ORVR control is in

widespread use (2010) and only about $700 per ton if Stage II is never

phased out. Under either scenario the cost effectiveness of the ORVR

option is attractive. Thus, even with the Stage II controls, it is more

cost effective to require ORVR controls on LDTs than to retain Stage II

solely for controlling LDT/HDV refueling emissions.

In addition to the VOC emission reduction benefits cited above, LDT

ORVR controls have other benefits. These benefits have not been

considered in the calculations above, but would further enhance the

attractiveness of LDT ORVR. LDT ORVR controls would result in an

average annual fuel savings equivalent to about 31 million gallons of

gasoline per year between the period 1998 and 2020 assuming no Stage II

phase-out, and about 43 million gallons per year if Stage II is phased

out. In addition, there will be health benefits as a result of

reductions in air toxic emissions. Best estimates are the avoidance of

2-3 cancer incidences per year as a result of lower refueling benzene

emissions. Additional cancer avoidances are possible depending on the

assumption regarding the toxicological impact of the remainder of the

constituents of the gasoline vapor. Reductions in potential non-cancer

health effects and welfare benefits such as reduced crop and material

damage due to ozone would occur as well.

In summary, EPA has decided to implement ORVR controls for LDTs for

several reasons: Their contribution to the VOC inventory is significant

and there is a need for additional VOC reductions to address air

quality concerns, the control is technologically feasible and

inexpensive, there are additional valuable benefits, and, as discussed

in the RIA, the cost effectiveness is very attractive, especially when

compared to other programs being implemented and under consideration.

The analysis shows that the cost effectiveness of implementing ORVR

controls for LDTs is superior to retaining Stage II controls for the

same purpose. The overall benefit to cost ratio for LDT ORVR is about

1.5. If the application of ORVR controls to LDVs and LDTs allows

phaseout of Stage II controls in the future, the cost savings

attributable to Stage II operations/ maintenance which would no longer

occur would make the average annual costs of ORVR controls negative (an

average annual savings of over $40 million). Based on the cost

effectiveness analysis and benefit-cost ratio, one could also justify

implementing LDT ORVR controls incremental to Stage II controls.

However, the long-term retention of Stage II would seem problematic

since it would be needed only for heavy-duty vehicles.

3. Heavy Duty Vehicles

In the NPRM, EPA proposed to require ORVR controls for all HDVs.

However, as discussed below, this requirement is not being finalized in

this rulemaking.

Information available to EPA indicates that an HDV ORVR system

would be conceptually similar to those applied LDVs and LDTs and the

initial costs should be relatively small. However, motor vehicle

manufacturers have argued that the design and production of ORVR

systems for HDVs would be considerably more difficult than for LDVs and

LDTs. Commenters have maintained that the technological step from

light-duty technology is greatest with regard to HDVs which have the

largest fuel tanks and different fuel/vapor system component designs

and configurations than many smaller LDTs. Comments regarding

incomplete HDVs expressed concern that secondary manufacturers would

improperly modify or incorrectly complete the vehicle fuel system

(which is usually not fully installed for incomplete HDVs) and perhaps

affect the proper function of the manufacturer-provided ORVR system.

Concern was also expressed that secondary manufacturers might not have

the expertise to correctly install the ORVR systems in all cases. In

each case the primary manufacturer may have legal liability for

potential problems. It is also worth noting that many HDVs are also

produced by the primary manufacturer as an incomplete HDVs, perhaps

compounding the concern.

EPA recognizes the manufacturers' strong concerns about ORVR

implementation issues that are unique to HDVs, and agrees that in many

cases the application of ORVR controls to HDVs would be more difficult

than for LDTs. Oftentimes the fuel and vapor control systems are

differently configured than those on LDTs and the fuel tanks are larger

and of different design. The large number of commercial applications

for HDVs leads to a larger number of unique body/chassis designs (e.g.,

12 passenger vans, crew cabs, long bed pick-ups, dual wheel axle

trucks) and thus a larger number of different fuel system

configurations. Another significant difference is that the engine in

the HDV would be certified separate from the ORVR system and thus there

are additional challenges in matching the canister purge provided by

the engine with the needs of each ORVR system. The manufacturers'

comments discussed above lay out the special concerns for incomplete

HDVs, including potential legal liabilities for the primary

manufacturer. Finally, it should be noted that unlike LDVs and LDTs EPA

is not aware of any prototype ORVR-equipped HDVs.

Given these concerns, the effort needed to implement LDV and LDT

ORVR systems, the relatively small number of gasoline-fueled HDVs, and

the fact that the application of ORVR standards to HDVs is

discretionary, EPA is not finalizing the portion of the NPRM which

applies to HDVs.

Even without implementing HDV ORVR requirements at this time, the

ORVR program still provides significant benefits. When viewed as a

percentage of sales, ORVR still applies to 91 percent of all gasoline-

fueled trucks and 97 percent of all gasoline-fueled vehicles.

Similarly, control is still achieved over 86 percent of all gasoline-

fueled truck refueling emissions and 94 percent of all gasoline vehicle

refueling emissions. Thus, EPA's final decision that ORVR requirements

are not required for these vehicles does not significantly reduce the

effectiveness of the ORVR program.

4. Applicability to California Vehicles

As discussed further in the summary and analysis of comments,

today's final rule implements a federal standard applicable to all

vehicles sold in the United States. Based on the language in section

202(a)(6) of the Act, EPA considers refueling emissions control to be

an evaporative standard. Although California has motor vehicle

standards in place for model year 1998 and beyond, including

evaporative emission standards, to date EPA has issued no section

209(b) waivers which consider a federal ORVR refueling program when

evaluating the protectiveness, in the aggregate, of those standards.

However, EPA interprets section 209(b)(3) to provide that once a

section 209(b) waiver is granted, compliance with the state program is

deemed compliance with the federal program standards. (See 42 FR 3193,

January 17, 1977). To the extent that a new federal standard is

established subsequent to a waiver, such standard will be considered in

a waiver reconsideration or future waiver request consideration. EPA is

making no finding at this time how stringency, in the ORVR context, may

be considered in a waiver proceeding, should one occur. (It should be

noted that EPA in this notice is restating its consistent

interpretation for the convenience of rulemaking participants, and does

not intend to reopen for reconsideration the issue of the effect of

existing section 209(b) waivers on post-waiver regulations.)

The California Air Resources Board (CARB) staff has held one

workshop to discuss the proper application of refueling control

(November 2, 1993). CARB is considering three courses of action:

adopting the federal ORVR rule, adopting a California-specific ORVR

rule, test, or standard, or maintaining that California's current motor

vehicle program, taken in the aggregate, is at least as stringent as

the federal program notwithstanding the lack of ORVR controls. If

California submits a waiver request for its evaporative emission

control program applicable to model year 1998 or thereafter, which does

not include federal ORVR requirements, EPA will decide at that time

whether California's motor vehicle program is at least as protective as

the federal program.

5. Fuels Covered

In the September 1991 and May 1993 notices, EPA specifically

solicited comments on applying the ORVR requirements to highway motor

vehicles powered by fuels other than gasoline. Consistent with EPA

policy on fuel neutrality and establishing a consistent set of

requirements for all fuels, today's rule requires that LDVs and LDTs

operating on any fuels be capable of meeting the refueling emission

standard described below. It applies to vehicles certified under both

40 CFR part 86 and 40 CFR part 88. Although many commenters stated that

the refueling standard should not apply to vehicles operating on diesel

fuels, the section 202(a)(6) requirement by its terms applies to all

LDVs regardless of the type of fuel used. (In contrast, section 202(k)

requires evaporative emission controls only for ``gasoline-fueled motor

vehicles''.) However, EPA has attempted to tailor the refueling

emission certification requirements to the fuel used.

Manufacturers of vehicles capable of operating on gasoline,

alcohol, or gasoline/alcohol blends must show that these vehicles

comply when refueled with such fuels through testing as described later

in this preamble. This requirement applies to dedicated neat alcohol

fuel vehicles and vehicles using alcohol blends. Bi-fuel or dual-fuel

vehicles must meet the requirements on both fuels. Flexible-fueled

vehicles must meet the requirements on all fuel combinations. At the

present time the only alcohol fuel affected is methanol.

However, a waiver of emission testing requirements is available for

those vehicles/fuels which are considered to be inherently low in

refueling emissions. EPA believes that a general engineering evaluation

approach is acceptable for diesel vehicles and diesel fuels for several

reasons. Diesel fuel today has a Reid Vapor Pressure (RVP) of less than

one pound per square inch (psi) (7 kPa) and diesel engines today do not

raise the temperature of fuel in their tanks substantially more than do

gasoline engines (less than 130 deg.F under most conditions). For

these reasons, the vapor space over the fuel in diesel tanks has a very

low concentration of fuel vapor compared to that in gasoline tanks and

thus displacement refueling emissions are low. EPA thus expects diesel

fuel vehicles to meet the refueling emission standard without a control

system.

Under this approach, the vehicle manufacturer's certification

application must include a statement that there is nothing about the

vehicle, its fuel system, or fuel that is counter to EPA's assessment

as discussed above, and the manufacturer's certification that the

vehicle meets the refueling emission standard (even without a control

system).

EPA retains the opportunity to test vehicles to ensure that they

comply with the emission standard during certification confirmatory

testing, Selective Enforcement Audits, and in-use testing. EPA also

retains the right to retract the engineering evaluation option for

diesel vehicles if the RVP of in-use diesel fuel increases or is

expected to increase beyond 1 psi (7 kPa) or a significant increase in

fuel tank temperatures is expected.

Since exhaust and evaporative emission requirements now exist for

all new methanol-fueled (neat and blend) vehicles, these shall be

required to comply with the ORVR standards under the same phase-in

schedule as gasoline-fueled vehicles. EPA expects that these vehicles

will use a technology similar to that used to comply with the

evaporative emission requirement.

The refueling control requirement will be applied to other

dedicated, dual-fuel, bi-fuel, and flexible-fuel vehicles using other

fuels (e.g., dedicated and hybrid electric vehicles, ethanol and

ethanol blends, compressed and liquid natural gas, liquified petroleum

gas) as regulations covering these fuels are implemented in the future.

Lead time, safety, and other factors will be considered in the course

of these actions. Full testing and engineering evaluation certification

options will be considered.

B. Implementation

1. Leadtime, Effective Model Year and Phase-in Requirements

Section 202(a)(6) of the Act specifies a four model year lead time

before ORVR requirements are to become effective for LDVs (``vehicles

manufactured beginning in the fourth model year after the model year in

which the standards are promulgated''). After this four-year lead time,

a three-year phase-in period begins, during which 40 percent, 80

percent, and 100 percent, respectively, of each manufacturer's sales of

new LDVs will need to meet the ORVR requirements. Today's action is

occurring early in the 1994 model year. Thus, ORVR requirements for

LDVs will become effective with the 1998 model year. At least 40

percent of each manufacturer's LDV sales will need to meet ORVR

requirements in model year 1998, 80 percent for model year 1999, and

100 percent for model years 2000 and later.

Since the application of ORVR requirements to LDTs is under the

general authority in section 202(a)(1), the specific lead time and

phase-in requirements of section 202(a)(6) do not automatically apply.

Rather, the standard ``shall take effect after such period as the

Administrator finds necessary to permit the development and application

of the requisite technology, giving appropriate consideration to the

cost of compliance `` (Section 202(a)(2)).

As discussed elsewhere in this preamble, EPA believes that the

nature of ORVR technology for LDTs will be very similar to that for

LDVs and that the cost of controls, incremental to the cost of enhanced

evaporative emission controls, is minimal. EPA also does not believe

that ORVR controls for LDTs present different safety issues than

canisters on LDVs where there is now general consensus that there are

no unreasonable risks. We therefore believe that the lead time required

for developing these systems could be similar regardless of vehicle

class.

While several commenters requested a delay in the LDT ORVR

requirement, commenters did not indicate that it was not technically

feasible to develop ORVR controls for LDTs during this timeframe.

However, comments from the vehicle manufacturers did express a concern

that resource and facility constraints would make simultaneous

development of ORVR systems for LDVs and all trucks problematic. They

have also indicated that design, development and some in-use experience

with ORVR systems on passenger cars would be helpful in the design of

LDT systems.

EPA has concluded that the resource and facility concerns expressed

by the manufacturers and the desirability for in-use experience with

ORVR systems can be balanced against the need for emission reductions

by beginning the phase-in of ORVR requirements for LDTs after the

program for LDVs has been fully implemented. In the mid-to-late 1990's

gasoline-powered vehicle manufacturers will need to respond to new

evaporative emission requirements, cold CO exhaust emission standards,

and California and Clean Fuel Fleet exhaust emission standards among

others. Most of these requirements apply to all three vehicle classes

and entail several hundred vehicle/engine families. Under the statutory

requirement the manufacturers will need to comply with LDV ORVR

requirements in the same timeframe. And while complying with the

enhanced evaporative and ORVR requirements simultaneously using an

integrated control system reduces the burden relative to separate

approaches for LDTs, a delay for LDTs is not unreasonable given the

already existing requirements. This trade-off is also acceptable in the

short-term since Stage II refueling controls are or will be in place in

many ozone NAAs. However, for the reasons discussed above, EPA believes

that ORVR controls are the preferred long term approach for control of

refueling emissions from LDTs.

Therefore, the requirements promulgated today for LDTs will be

implemented in two stages. The first stage will cover LDTs with a GVWR

of 6,000 or less (LLDT), the second will cover LDTs with a GVWR of

6,001 to 8,500 lbs GVWR (HLDT). LLDTs represent about 70 percent of LDT

sales. HLDTs represent the remaining 30 percent. For LLDTs, the ORVR

requirement will begin implementation in the 2001 model year and will

phase in over three model years according to the same percentages as

LDVs. For HLDTs, the ORVR requirement will begin implementation in the

2004 model year and will phase in over three model years according to

the same percentages as LDVs (40/80/100). This schedule will permit the

development and application of cost-effective, economically achievable

technology, as required by section 202(a)(2) and will still allow

consideration of the Stage II phaseout provisions of section 202(a)(6)

of the CAA in the long term.

Provisions of 40 CFR 86.085-1(b) permit manufacturers to certify

HDVs with a GVWR of 8,501-10,000 lbs GVWR as LDTs. This option will

remain in effect for refueling controls. HDVs certified under this

option would be treated as HLDTs for purposes leadtime, phase-in and

sales compliance determination.

EPA does not view the provisions of section 202(a)(3) as applying

to refueling controls, as that provision was probably intended to apply

only to exhaust emission standards, as did its predecessor provision.

However, even if it did apply, this section would provide for at least

four years of leadtime. Since EPA is allowing this much leadtime for

HLDTs anyway, designating section 202(a)(2) or 202(a)(3) as authority

for HDV leadtime has no practical significance here.

2. Small Volume Manufacturers

Today's rule includes a short-term provision for small volume

light-duty vehicle manufacturers. Several small volume manufacturers

commented that, as a practical matter, they cannot phase in their

compliance due to their small size and limited product lines. Small

volume manufacturers also claimed that they sometimes rely on control

technology developed by larger manufacturers to develop their

compliance strategies, and this would not be possible if they must

comply at essentially the 100 percent of sales level before the larger

manufacturers. R&D cost concerns were cited as obstacles as well.

EPA believes that these comments state valid concerns. As is

described in three recent Federal Register notices, EPA has allowed

small volume manufacturers to delay compliance to the last model year

of the phase-in: in the Tier 1 exhaust emission standard rule (June 5,

1991, 56 FR 25724), the cold CO exhaust emissions rule (July 17, 1992,

57 FR 31888), and the enhanced evaporative emission standards rule

(March 24, 1993, 58 FR 16003), and has decided to allow the same

accommodation for the ORVR requirement for light-duty vehicles. This

provision is included, not only for the reasons raised by the

manufacturers, but also because it would be inconsistent to face ORVR

compliance before evaporative emission compliance when the comments

indicate that most manufacturers plan to use integrated refueling/

evaporative control systems and these are desirable for both cost and

safety reasons. In addition, requiring phased compliance for these

manufacturers effectively denies them the opportunity Congress intended

to phase in the control technology. (Cf. State of Ohio v. EPA, 997 F.

2d 1520, 1535 (D.C. Cir. 1993) (de minimis exception to seemingly

literal statutory language can be allowed where failure to allow the

exception frustrates a Congressional goal or leads to absurd results)).

Thus, small volume manufacturers of light-duty vehicles, as defined in

40 CFR part 86, may delay compliance to model year 2000 (i.e., the

third model year of the phase-in), but must comply with 100 percent of

sales in that and subsequent model years. Because of the additional

leadtime EPA is affording to LDTs, the Agency is not implementing this

small-volume manufacturer provision for these vehicles.

3. Inclusion of Inherently Low Refueling Emission Vehicles

As was discussed in the May 1993 notice, vehicles meeting the

refueling emission standard because they are inherently low in

refueling vapor emissions (those certified without a control system

using the engineering evaluation option), and thus are waived from

testing, cannot be counted in either the vehicles complying or base

sales figures in determining compliance with the sales requirements of

the statute. Compliance for these vehicles is to be calculated

separately.

C. Refueling Emission Test Procedures and Standard

This final rule includes test procedures for the measurement of

refueling emissions and a corresponding emissions standard by which to

judge the adequacy of ORVR control system designs. The test procedures

accommodate integrated system designs, which control both refueling and

evaporative emissions with a common vapor storage unit, as well as non-

integrated system designs, which do not share vapor storage units.

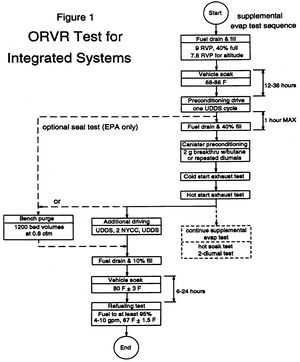

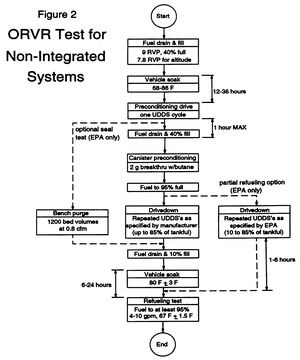

The test procedures for these two types of control systems,

although different in some ways (explained below), involve the same

basic steps: Load the storage canister with hydrocarbon vapor, drive

the vehicle to provide opportunity for canister purge, and refuel the

vehicle while measuring emissions (see Figures 1 and 2). The first two

steps together are referred to as the preconditioning phase and are

discussed in detail further on in this section.

BILLING CODE 6560-50-P

BILLING CODE 6560-P-C

1. Refueling Emissions Test

The procedure for the refueling step is common to both integrated

and non-integrated systems. It involves disconnecting the vapor line

from the fuel tank to the canister, draining the fuel tank, refueling

with test fuel to 10 percent of the nominal tank capacity, soaking the

vehicle for 6 to 24 hours at 80

BILLING CODE 6560-P-C

1. Refueling Emissions Test

The procedure for the refueling step is common to both integrated

and non-integrated systems. It involves disconnecting the vapor line

from the fuel tank to the canister, draining the fuel tank, refueling

with test fuel to 10 percent of the nominal tank capacity, soaking the

vehicle for 6 to 24 hours at 803 deg.F

(26.71.7 deg.C), reconnecting the vapor line, and fueling

the vehicle with test fuel at 671.5 deg.F

(19.40.8 deg.C) in a sealed enclosure (SHED) while

measuring emissions. Fueling is performed at a rate of 4 to 10 gallons

per minute (15.1 to 37.9 liters per minute) and is terminated at the

first automatic shutoff that occurs after a quantity of fuel has been

pumped equal to at least 85 percent of the nominal tank capacity.

One of the key issues raised in the July 1993 hearing and the

subsequent comment period concerned the test temperature specifications

for the dispensed fuel and the residual in-tank fuel, both of which

have a major impact on the refueling vapor generation and therefore on

ORVR system designs. Hearing participants discussed the merits of

setting the test dispensed fuel temperature at 67 deg.F (19.4 deg.C)

while maintaining the residual in-tank fuel temperature specification

of 80 deg.F (26.7 deg.C). Previous proposals had included a dispensed

fuel temperature specification of 81-84 deg.F (27.2-28.9 deg.C).

Comments were received on both sides of this issue. The

manufacturers supported the test temperature specifications discussed

at the July 1993 hearing. They believed these specifications would

enable the canisters planned for meeting the enhanced evaporative

emission requirements to also capture refueling emissions and would

facilitate the use of liquid seals as an option to mechanical seals in

the fillneck. Manufacturers commented that this would provide much

needed design flexibility and alleviate their safety concerns. The

American Petroleum Institute (API) and the Natural Resources Defense

Council (NRDC) supported the 81 deg.-84 deg.F dispensed temperature

range proposed earlier. They expressed concern that 67 deg.F is not

representative of actual dispensed fuel temperatures on high ozone days

and therefore might lead to a situation where the test procedure does

not adequately represent in-use conditions with the result that

refueling emissions are controlled inadequately in use.

EPA's goal in establishing test parameters is to ensure that the

combination of test conditions results in designs that will achieve a

very high level of control in use. Therefore, the representativeness of

any one test parameter, such as dispensed fuel temperature, is of less

concern than the net effect of the total test. For example, in-use RVPs

in many parts of the nation during the summer months are lower than

that specified in the test. What is important is the combined effects

of the key parameters during an in-use refueling event. EPA's analysis

of in-use effectiveness described in the Regulatory Impact Analysis and

Summary and Analysis of Comments indicates that these test conditions

will yield designs that achieve in-use control in excess of 95 percent

during the ozone season in the NAAs (even assuming the accuracy of data

showing that one region of the country has dispensed fuel temperatures

within or exceeding the 81 deg.-84 deg.F range, a potentially

questionable assumption, as explained in the next paragraph). Based on

this analysis and the manufacturers' comments, EPA has concluded that

the test specifications being finalized in this action are appropriate.

The dispensed gasoline temperature parameter discussed in the NPRM

was derived using limited survey information on in-use refueling

events. The 81 deg.-84 deg.F dispensed temperature value in the NPRM

was driven by refueling events in the Southeastern U.S. These dispensed

fuel temperature values are seven or more degrees higher than any other

region of the country. There is no obvious technical reason why the

Southeastern U.S. values were so much higher than those found in other

regions of the country. Thus, there is some possibility that they may

be unrepresentative, in which case the 67 deg.F temperature

used in the refueling test is even more representative. (EPA is not

completely disavowing the Southeastern U.S dispensed fuel data, since

it is the only data available to EPA at this time. The Summary and

Analysis of Comments contains an analysis of the sensitivity of the in-

use effectiveness of the ORVR requirement to this dispensed temperature

value.)

2. Integrated System Preconditioning

The nature of integrated systems allows for a corresponding

integration of ORVR and evaporative emission preconditioning

procedures. This integration is desirable because of potential test

resource savings. A major revision of the evaporative emission test

procedure was completed recently and will be implemented beginning in

the 1996 model year (58 FR 16002, March 24, 1993).

EPA proposed three integrated system preconditioning options for

the refueling test in the May 1993 Federal Register notice. Option A

places the refueling test after the exhaust emissions portion of the

supplemental evaporative emissions test procedure. Option B places the

refueling test after the running loss portion of the evaporative

emissions test sequence. As a logical extension to this option, EPA

also proposed Option B1, which adds more driving to Option A in order

to allow for more purging of the canister, similar to Option B, while

avoiding the complexities of the Option B running loss procedure.

EPA has selected Option B1, based on the above-described advantages

and the support for this choice expressed by commenters. This procedure

follows the supplemental evaporative emission test preconditioning

procedure, involving an initial fuel tank drain and fill with

certification test fuel to 40 percent full, a 12 to 36 hour soak at

68 deg. to 86 deg.F (20 deg. to 30 deg.C), a preconditioning drive

over one Urban Dynamometer Driving Schedule (UDDS) cycle, another fuel

tank drain and fill to 40 percent, a canister preconditioning step

detailed below, and then the exhaust emissions test. At this point the

refueling test departs from the evaporative test sequence. Instead,

additional driving is conducted to provide more opportunity for

canister purge. This driving consists of a UDDS cycle followed by two

New York City Cycles (NYCC) and then by another UDDS. This driving

schedule corresponds to the driving specified for the evaporative

running loss test, though not at the same high temperatures. After the

driving, the above-described refueling procedure is conducted.

The canister is preconditioned by loading it with a 50/50 mixture

of butane and nitrogen, at a rate of 40 grams of butane per hour, until

2 grams of hydrocarbons are emitted from the canister (referred to as

the 2-gram breakthrough point). Alternatively, the canister can be

loaded to this point with gasoline vapors by conducting repeated

diurnal heat builds. All detailed aspects of the supplemental

evaporative emission test procedure, up through the exhaust emission

test, apply to integrated ORVR system testing as well (58 FR 16002,

March 24, 1993). The three test sequences (full 3-diurnal evaporative,

supplemental evaporative, and refueling) may be performed in any order

and exhaust emissions measurements from any of the three may be

considered valid. If either evaporative emission sequence has been

conducted before the refueling test, the fuel tank drain and fill and

vehicle soak that precede the one UDDS preconditioning drive in the

refueling test sequence may be skipped.

3. Non-Integrated System Preconditioning

Non-integrated ORVR systems store only refueling vapors and

therefore warrant a preconditioning drivedown of 85 percent of the fuel

tank capacity before being subjected to the 85 percent refueling event.

This driving consists of repeated UDDS cycles, either on a track or on

a dynamometer, until a volume of fuel equal to 85 percent of the fuel

tank nominal capacity has been consumed. During the actual refueling

test, the vehicle will be filled to at least 95 percent of tank

capacity, as is the case for the integrated system. If manufacturers

exercise the option to do less driving in certification testing, EPA

may perform subsequent confirmatory and in-use testing using the same

reduced driving schedule.

At its discretion, EPA may test non-integrated systems with a

partial refueling test procedure. This procedure helps to ensure

control in those in-use refueling events in which less than a tankful

of fuel is pumped. Because the non-integrated system test allows a

nearly complete drivedown of the fuel tank capacity, thus enabling

purge design strategies that inappropriately minimize purge during the

exhaust emissions test, EPA considers the partial refueling test

necessary. It also allows EPA to assess the basic question of whether

the system has the capacity to handle a partial fill, a common

refueling event in use.

In this partial fill test, following the loading of the canister

with butane and fueling of the vehicle to 95 percent of the fuel tank

capacity, the vehicle will be driven some integer number of UDDS cycles

such that some amount of fuel between 10 and 85 percent of the fuel

tank capacity is consumed. After a one to six hour soak, the vehicle

will be subjected to the refueling emissions measurement test with no

intervening drain and fill. The fuel pumped in the test will be a

metered amount, corresponding to the amount consumed in the drive. This

amount will be based on the vehicle's fuel economy, as determined at

certification.

4. Seal Test

Also at its discretion, EPA may perform a seal test of integrated

and non-integrated designs, aimed at verifying the integrity of

fillpipe seals and vapor lines. This test eliminates consideration of

potential canister emissions by thoroughly bench purging the canister

prior to the refueling event. The canister preconditioning and

preparatory driving are therefore likewise eliminated, although EPA may

perform the test procedure up through the exhaust emission test (in

order to obtain this measurement) and then conduct the bench purge and

refueling test. Failure of the seal test would be considered equivalent

to failing the full refueling emissions test and the same standard

would apply to both.

5. Cap Removal Emissions

In the May 1993 Notice, EPA requested comment on including a test

to measure and control the ``puff loss'' emissions from a pressurized

fuel tank when the fuel cap is removed for refueling.

In addition to refueling emissions, vehicles can have emissions

when the fuel cap is removed from a pressurized fuel tank before the

refueling event. Although these emissions potentially warrant control,

EPA does not view them as ``refueling'' emissions for purposes of

section 202(a)(6), since they precede a refueling and are more akin to

evaporative emissions. EPA in fact proposed, but did not finalize, such

a cap-off test in the evaporative emissions NPRM (55 FR 1914, January

19, 1990) rather than in the ORVR NPRM. Thus Congress would not have

been considering such emissions when it enacted the 95 percent minimum

control standard in section 202(a)(6) in the 1990 CAAAs.

Manufacturers commented that the puff loss test would provide no

additional control over that achieved by the refueling test and the

evaporative emissions rule requirement that tanks pressurized to over

10'' (25 cm) H2O be vented to the canister upon cap removal. EPA

disagrees with this assessment. The refueling test does not measure

emissions from cap removal directly after vehicle operation. The

evaporative emissions requirement allows for the venting of tank

pressures under 10'' H2O to the atmosphere. These emissions can be

appreciable. General Motors (GM) calculated that the puff loss from

venting a 10 percent full, 20 gallon (76 liter) tank at 10'' H2O

would be about 3 grams. EPA agrees with this estimate but disagrees

with the contention that this is minor, given that this same vehicle

would only be allowed to emit a little over 3 grams during the

refueling test.

GM also argued that the execution of a cap-off test involving a

warm-up drive followed immediately by a cap-off step in a SHED would be

complex and formidable. EPA agrees with GM's contentions that hot soak

emissions could confuse the puff loss measurement and that the time

required to move a vehicle from a dynamometer cell to a SHED and remove

the cap would be overly long compared to the actual in-use event, which

typically involves less than a minute from key-off to cap-off. These

two concerns would affect the measured emissions in opposite directions

and would make it difficult to ascertain a puff loss emission

corresponding to the in-use event.

EPA remains concerned about puff loss emissions, particularly

considering that the new evaporative emission control requirements may

prompt manufacturers to rely more heavily on pressurized tank designs

in the future. However, EPA believes it necessary to defer action on

this issue so that an effective test procedure can be developed,

involving more complete public participation. Therefore, EPA is leaving

this portion of the rulemaking open for now and intends to take up this

issue as part of the planned further action on pressurized designs

announced in the evaporative emissions control final rule (58 FR

16012). However, it should be noted that the enhanced evaporative

emissions rule will require controls for systems whose pressure exceeds

10 inches H2O, and thus control is already in place for these

extreme situations.

6. Spitback Test

EPA believes, and manufacturers' comments indicate, that vehicles

would not be expected to comply with the refueling emission standard if

they emitted significant spitback emissions during the refueling test.

Fuel spilled on the side of the vehicle or in the SHED when the fuel

nozzle shuts off will evaporate and be included as part of the

refueling emissions. In recognition of this effect, this final rule

also waives the spitback testing requirement for vehicles being

certified to meet the ORVR requirements. Similar to the provision for

``inherently low refueling emission vehicles'' discussed above,

manufacturers can, at their option, certify as part of the

certification application, that they agree with EPA's assessment

regarding the effect of spitback emissions on the ability to pass the

refueling emission standard and that their vehicle passes the spitback

test standard. Of course, manufacturers may elect to comply with the

spitback test in lieu of using this waiver option.

Compliance with the spitback standard is still required, and EPA is

retaining the spitback test and standard promulgated in the enhanced

evaporative emissions control rule (58 FR 16002, March 24, 1993). EPA

may conduct or require manufacturers to conduct the spitback test to

demonstrate compliance should concerns over vehicle spitback arise.

7. Nozzle Geometry Standards

In the NPRM, EPA asked for comment on the need for fuel nozzle

geometry standards as part of an ORVR program, and suggested that auto

makers and nozzle manufacturers undertake a voluntary initiative to

develop national consensus standards in this area. This initiative is

being undertaken under the auspices of the Society of Automotive

Engineers (SAE). An SAE technical committee, comprised of auto maker,

fuel nozzle manufacturer, and other representatives, is considering

revisions to SAE standard J285 ``Gasoline Dispenser Nozzle Spouts''.

It is important that nozzles used in the design and testing of

ORVR-equipped vehicles be similar to those found in use. Should this

committee reach consensus on fuel nozzle geometry specifications, EPA

will use a nozzle meeting this standard in all refueling emissions

compliance testing, if the nozzle manufacturers agree to adopt these

specifications for future retail and commercial fuel nozzles and the

auto manufacturers design their ORVR systems to accommodate a nozzle

with this geometry. If no standard is developed for nozzle geometry or

if the above agreements cannot be reached, EPA will use any

commercially available nozzle in its testing.

8. Level of the Standard

This final rule adopts a refueling test standard of 0.20 grams of

hydrocarbon emissions per gallon (g/gal) of fuel pumped (0.053 g/

liter). This standard applies to all vehicle classes covered by this

rule and covers the full useful life. Setting the standard at this

level ensures that the standard that meets the statutory requirement to

provide a minimum emission capture efficiency of 95 percent, as

discussed below.

The August 1987 NPRM included a proposed refueling emission

standard of 0.10 g/gal (0.026 g/liter) of fuel pumped, which at that

time represented about a 98 percent emissions reduction from

uncontrolled levels. Subsequently, the 1990 CAAA called for a refueling

emission standard representing at least a 95 percent reduction over

uncontrolled levels. EPA determined that this reduction corresponds to

a standard of about 0.25 g/gal (0.066 g/liter) and requested comment in

the May 1993 notice on the setting of a standard in the 0.10 to 0.25 g/

gal range.

Manufacturers supported a standard of 0.20 g/gal, arguing that this

standard would satisfy the CAA minimum requirement while providing for

full useful life compliance and design flexibility. API and other

commenters felt that a standard providing a 98 percent level of control

is justified based on demonstrated and cost effective technology.

After analyzing the comments and the projected in-use emission

impacts, EPA has selected a standard of 0.20 g/gal. This standard was

chosen because it meets or exceeds the statutory minimum requirement

and, since it is representative of most refueling situations reasonably

likely to occur (Cf Edison Electric Institute v. EPA, 2F.3J 438, 446-47

(D.C. Cir. 1993)). At the same time, it meets the manufacturers' need

for adequate design margin and flexibility. As is discussed in the

Summary and Analysis of Comments, the nature of the canister-based

control technology is such that setting the standard at a lower level

would not be expected to achieve additional emission reductions in use.

Systems will need to be designed for essentially zero emissions, with

the standard providing an allowance for vehicle and test variability.

It may also enhance the use of liquid fillneck seals which are

projected to have lower costs, good in-use performance, and present no

safety concerns.

D. Safety of ORVR Systems

1. Background

Section 202(a)(6) of the 1990 CAA Amendments (as well as its

predecessor provision) requires EPA to consult with the Secretary of

Transportation regarding the safety of vehicle-based (ORVR) systems for

the control of vehicle refueling emissions. EPA began this consultation

in the Spring of 1986, prior to the NPRM, and the consultation has

continued throughout the various stages of this rulemaking. DoT was

represented by NHTSA throughout this process. A record of this

consultation and the various analyses conducted by EPA and NHTSA to

assess the safety issue is available in the public docket and is

discussed in the April 15, 1992 Federal Register notice regarding ORVR

controls (57 FR 13220). Early in the consultation process, NHTSA raised

concerns about the safety of ORVR canister systems, and throughout the

various stages of the rulemaking, safety has been a central issue in

the public comments and in the deliberations on the ORVR rulemaking.

Unresolved concerns regarding the safety of ORVR canister systems (at

least relative to Stage II systems) delayed promulgation of the NPRM

prior to the 1990 CAAAs and, in April 1992, led EPA to decide not to

require ORVR controls at that time. Given the concerns raised about

vehicle safety, it is important to address the potential safety

concerns as part of the implementation of the ORVR requirement.

2. Test Procedure/Safety

The safety comments regarding ORVR canister systems focused

primarily on the concern that ORVR systems would increase fuel system

complexity and that this would create vehicle safety risks. Many

manufacturers' comments on the NPRM indicated that the test procedure,

as proposed in 1987, would force the use of non-integrated (separate)

systems for refueling and evaporative emissions control. They

characterized these systems as making the fuel vapor control system

more complex than current evaporative control systems, thus creating

the potential for a safety risk.

As noted earlier, the DC Circuit held that the consultation

requirement in section 202(a)(6) does not alter EPA's duty to issue

ORVR requirements. After the decision was issued and after publication

of EPA's May 27, 1993 Federal Register notice (58 FR 30731), EPA held

technical discussions with representatives of AAMA regarding the ORVR

test procedure (See items IV-E-101,102,105,106 in the public docket for

this rulemaking). The purpose of these discussions was to identify

potential changes to the ORVR test procedure which, if enacted, would

facilitate the use of an integrated evaporative/refueling control

system approach with a liquid seal in the fillneck. (As was discussed

above, in March 1993, EPA published a final rule requiring enhanced

evaporative controls on gasoline-powered LDVs, LDTs, and HDVs. The

enhanced evaporative requirements will lead to an increase in the size

of the canister used to capture evaporative emissions, an upgrade in

the purge system capabilities, as well as other system changes and

improvements.) An integrated system approach would allow manufacturers

to make use of the upgraded evaporative control hardware (common carbon

canister, purge system, vapor hoses, etc.) as part of their ORVR

control strategy and thus address both system complexity and cost

issues. This approach would be used in lieu of the non-integrated

control system approaches which were characterized as being complex and

potentially less safe.

ORVR test procedure changes which would ease the use of integrated

evaporative/refueling control systems with liquid fillneck seal

approaches were identified. EPA explained this option at the July 22,

1993 public hearing and requested additional public comment.

Auto manufacturer comments supported this approach. For example,

Chrysler Corporation's comments indicated:

``Chrysler believes that the proposed AAMA revisions to the test

procedure and the 0.20 g/gal. standard will allow Chrysler to design

safe, efficient ORVR systems.''

Ford Motor Company's comments stated:

``Ford recommends that EPA adopt the test procedure changes and

standards outlined by AAMA at the Hearing on July 22, 1993, and

contained in the attached comments. These changes should allow for

the design and development of a canister-based, integrated refueling

and evaporative emissions system which is less complex than a

nonintegrated system and which addresses the safety issues raised in

previous rulemakings. These procedural changes along with others

identified in the comments should allow EPA, in consultation with

NHTSA, to find that integrated systems do not present an

unreasonable risk to automotive safety.''

General Motors expressed similar views:

``The ORVR test procedure changes described in these comments

are critical to permitting manufacturers to develop ORVR systems for

passenger cars that minimize or eliminate any adverse impact upon

motor vehicle safety.''

And, in summary, an October 13, 1993 AAMA letter to NHTSA stated

that:

``We believe this procedure will allow the use of an integrated

ORVR/evaporative emissions system including a common carbon

canister. An integrated ORVR/evaporative emissions system will allow

manufacturers to design and build safe, efficient ORVR systems.''

Comments by other manufacturers also supported this position.

Accordingly, this rule enacts the test procedure option identified

above. It is supported by AAMA, the Association of International

Automobile Manufacturers (AIAM), and the individual manufacturers and,

according to their comments, minimizes their longstanding vehicle

safety concerns.

3. DOT Consultation

In response to the changed circumstances since it's prior safety

analysis, DoT/NHTSA undertook an independent assessment of vehicle

safety concerns associated with ORVR systems. In November 1993, NHTSA

completed a study entitled ``An Assessment of Onboard Refueling Vapor

Recovery System Safety''. This document reexamined the conclusions

raised in their July 1991 study, upon which EPA relied heavily on its

April 1992 decision not to require ORVR controls.

In this recent study, NHTSA revisited the principal findings of its

July 1991 report to consider the positive safety impacts of the test

procedure changes and other changed circumstances. The NHTSA report,

which is available in the public docket, reached the following general

conclusion regarding ORVR safety:

``Basically, there were three principal areas of concern pointed

out in the July 1991 report: the increased size of vapor canisters

to hold the fuel vapors, the mechanical complexity of the ORVR

system, and the ability of the ORVR system to safely manage and

purge the increased volume of vapors.

As discussed above, technical developments, and test procedure

and regulatory changes that have occurred since the July 1991 safety

assessment, have had the net effect of reducing the safety concerns

raised in the July 1991 report. The majority of vehicle

manufacturers have stated that it is now possible to design safe

ORVR systems that will function properly under all operating

conditions. However, there still remains some small unquantifiable

increase in safety risk due to the addition of the ORVR systems.

This risk is unquantifiable since there are no data upon which to

base a numerical estimate.''

Thus, NHTSA views the changed circumstances, including the final

test procedure and the use of integrated systems, as addressing many of

their previous concerns. They also acknowledge that absent actual data

they cannot determine the level of risk, and thus conclude that risks

are unquantifiable. While the NHTSA report contained a brief assessment

as to why trucks might be different than cars and stated that truck

prototype systems and field tests for truck ORVR systems would be

beneficial, no special safety risks were cited for using ORVR canisters

to control LDT/HDV refueling emissions.

4. EPA Assessment

EPA is withdrawing its April, 1992 finding that ORVR canisters pose

unreasonable safety risks. First, that determination was based on an

improper comparison with Stage II controls. NRDC v. Reilly, 983 F. 2d

at 271. Considered on their own, ORVR canisters do not appear to pose

significant safety risks. Indeed, as the Agency noted in 1987, this

appears to be particularly true for integrated evaporative/refueling

control systems--which now appear to be the preferred control system.

Second, EPA is swayed because NHTSA has reviewed the safety of ORVR

systems in light of recent developments and subsequently has withdrawn

most of the adverse conclusions in the 1991 report. NHTSA also

indicates (1993 Report pp. 17-24) that some of its remaining concerns

can be addressed by choosing proper designs for canister systems. As

noted above, EPA has taken NHTSA's views strongly into account

throughout the course of this rulemaking, and accordingly is influenced

by NHTSA's more positive outlook on ORVR canister safety.