Federal Motor Vehicle Safety Standards; Metric Conversion |

|---|

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

Topics: National Highway Traffic Safety Administration, Federal Motor Vehicle Safety Standards

|

Barry Felrice

Federal Register

March 15, 1994

[Federal Register: March 15, 1994]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 93-87; Notice 1]

RIN 2127-AF03

Federal Motor Vehicle Safety Standards; Metric Conversion

AGENCY: National Highway Traffic Safety Administration (NHTSA), DOT.

ACTION: Notice of proposed rulemaking.

-----------------------------------------------------------------------

SUMMARY: This notice proposes to revise selected Federal Motor Vehicle

Safety Standards (FMVSS) by converting English measurements specified

in those standards to metric measurements. This proposed rulemaking is

the first of several that NHTSA will undertake to implement the Federal

policy that the metric system of measurement is the preferred system of

weights and measures for United States trade and commerce. The proposed

conversions are not intended to make any changes in the stringency of

the affected FMVSS.

DATES: Comments must be received on or before May 16, 1994.

ADDRESSES: All comments should refer to the docket number and notice

number in the heading of this notice and be submitted, preferably in

ten copies, to: Docket Section, room 5109, National Highway Traffic

Safety Administration, 400 Seventh Street, SW., Washington, DC 20590.

Docket hours are 9:30 a.m. to 4 p.m., Monday through Friday.

FOR FURTHER INFORMATION CONTACT: Mr. Kevin Cavey, National Highway

Traffic Safety Administration, 400 Seventh Street, SW., Washington, DC

20590. Mr. Cavey's telephone number is: (202) 366-5271.

SUPPLEMENTARY INFORMATION: Section 5164 of the Omnibus Trade and

Competitiveness Act (Pub. L. 100-418), makes it U.S. policy that the

metric system of measurement is the preferred system of weights and

measures for United States trade and commerce. Through Executive Order

12770, Federal agencies are directed to comply with the Act by adopting

a conversion schedule for their programs by September 30, 1992. In a

Federal Register document of April 21, 1992 (57 FR 14691), NHTSA

published its plan to use the metric system in NHTSA programs, and

included an implementation schedule to convert the Federal Motor

Vehicle Safety Standards (FMVSSs).

In the document, NHTSA stated its intent to review all the FMVSSs

that the agency expects will be in effect between June 1992 and 1997,

and to the fullest extent feasible, convert English system measurements

in those FMVSSs to the metric system. In undertaking the conversion of

the measurements in the FMVSSs, the agency identified the following

steps to be taken for each standard:

1. List the values to be converted.

2. Determine whether to convert the values to an equivalent

metric unit, or to use an exact conversion.

3. For the equivalent metric unit conversions, determine any

interrelationships with other values, and the effect of conversion

on the interrelationships.

4. Determine any impact that the conversion may have on changes

in safety.

5. Undertake rulemaking to revise the standard to reflect the

converted values.

With respect to the nature of the conversions to be made, the

agency stated that NHTSA generally favored the use of equivalent

conversions because using values stated in integers would facilitate

making measurements during compliance testing. However, NHTSA indicated

that it would not use equivalent conversions where there is a specific

safety need or other reason to make an exact conversion. (To illustrate

equivalent and exact conversions, an equivalent conversion of two

inches would be 50 millimeters, while an exact conversion would be 50.8

millimeters.)

The agency anticipated that some standards will be easier to

convert than others. Therefore, the agency established the following

timetable: Simple conversions to be completed by June 1994,

intermediate conversions by December 1996, and the most complex

conversions by December 1997.

NHTSA received comments on the plan from Ford Motor Company,

General Motors Corporation, Volkswagen of America, the Association of

International Automobile Manufacturers, and Mr. John T. Benedict, an

interested citizen. All the comments supported NHTSA's approach to

making the conversions. Some commenters cautioned the agency to be

careful when rounding off metric conversions, so that the agency does

not inadvertently make the standards more stringent. NHTSA agrees that

the conversions should not inadvertently result in making the standards

more stringent. In this first round of simple conversions, NHTSA has

made the conversions using SAE guideline J916 May 1991, and Federal

Standard 376B ``Preferred Metric Units for General Use by the Federal

Government'' and then rounding the result. NHTSA acknowledges Mr.

Benedict's comment that this approach may not be suitable for the more

difficult conversions to be made in subsequent rulemkings.

NHTSA generally agrees with Volkswagen's comments that measurements

and performance requirements should be expressed in the same units in

the FMVSS, the SAE recommended practices and standards, and the

Canadian Motor Vehicle Safety Standards. The agency will follow this

practice unless adopting levels consistent with other standards would

substantively change the existing requirements in the FMVSSs. With

regard to the simple conversions proposed in this notice, the agency's

approach of making a conversion and rounding to the nearest whole

metric unit results in numbers that are consistent with voluntary

industry guidelines, such as ASTM and SAE standards.

This initial notice of proposed rulemaking identifies those

standards for which the agency believes conversions would be simple and

makes the appropriate conversions to the metric system. English

measurements in the following Federal Motor Vehicle Safety Standards

(49 CFR 571 et seq.) are proposed to be converted to the metric system:

Standard No. 102, Transmission shift lever sequence, starter interlock,

and transmission braking effect; Standard No. 103, Windshield

defrosting and defogging systems; Standard No. 104, Windshield wiping

and washing systems; Standard No. 107, Reflecting surfaces; Standard

No. 110, Tire selection and rims; Standard No. 112, Headlamp

concealment devices; Standard No. 114, Theft protection; Standard No.

115, Vehicle identification number basic requirements; Standard No.

120, Tire selection and rims for motor vehicles other than passenger

cars; Standard No. 124, Accelerator control systems; Standard No. 126,

Truck-camper loading; Standard No. 205, Glazing materials; Standard No.

206, Door locks and door retention components; Standard No. 207,

Seating systems; Standard No. 212, Windshield, mounting, and Standard

No. 216, Roof crush resistance.

I. Exact Versus Equivalent Conversions

In the majority of cases, the proposed conversions are equivalent

conversions. It is the agency's intent that, if made final, these

equivalent conversions have no substantive effect on specifications or

requirements in the affected standard. Public comment is sought on

whether each equivalent conversion would substantively affect the

regulatory text. If there would be a substantive effect, comment is

requested on the appropriate exact conversion.

In certain cases, exact conversions are proposed. Most of the exact

conversions specify the height of lettering, the minimum depth to which

the lettering must be impressed, or the maximum height to which it must

be embossed. In such situations, manufacturers typically have invested

in molds and other materials that produce lettering of very precise

sizes. NHTSA does not want the conversion of the required lettering to

have the effect of requiring manufacturers to have to change molds and

materials.

NHTSA also proposes to use exact conversions for certain other

measurements, to avoid a possibility that the standard would become

more stringent after the conversion. For each of these proposed

conversions, the agency seeks comment on whether use of the equivalent,

rather than the exact conversion, would make a substantive difference:

1. Gross Vehicle Weight Ratings (GVWRs)

When the standards proposed to be converted in this notice refer to

GVWR, the agency proposes to convert those GVWRs to the exact

conversion. GVWRs of 10,000 pounds are proposed to be converted to 4536

kilograms and GVWRs of 6,000 pounds are proposed to be converted to

2,722 kilograms. NHTSA is aware that some of the Canadian Motor Vehicle

Safety Standards use the equivalent conversions of 4500 kilograms for

the 10,000 pound GVWR and 2700 kilograms for the 6000 pound GVWR.

The GVWR conversion may affect the applicability of some of the

FMVSS's to particular vehicles. In the case of standards that apply to

vehicles with a GVWR of 10,000 pounds or less, rounding to 4500

kilograms would affect any vehicles between 4501 and 4536 kilograms

GVWR. Such vehicles may be excluded from FMVSS's that had applied to

them (e.g., Standards 118, Power-operated window, partition, and roof

panel systems, and 212, Windshield mounting, which apply to vehicles

with GVWR's of 10,000 pounds or less), or be subject to requirements

that had previously not applied to them (e.g, Standard No. 222, School

Bus Passenger Seating and Crash Protection which applies to vehicles

with GVWR's of more than 10,000 pounds).

Since the number of vehicles in the 4501 to 4536 kilogram or 2700

to 2722 kilogram ranges is likely to be very small, NHTSA requests

comments on whether the greater ease of using equivalent conversions

would outweigh the benefits of exact conversion.

2. Standard No. 110, Tire Selection and Rims

Standard No. 110 specifies at S4.4.1(b) that tire rims shall, in

the event of rapid loss of inflation pressure at a speed of 60 miles

per hour, retain the deflated tire until the vehicle can be stopped. In

this NPRM, the agency proposes that 60 miles per hour be converted to

97 kilometers per hour, the exact conversion. The Canadian Motor

Vehicle Safety Standards currently specify the requirement be met at

100 kilometers per hour, which is the equivalent conversion. The agency

seeks comment on whether there is a substantive difference whether the

conversion of 60 miles per hour is made to 97 or to 100 kilometers per

hour.

3. Standard No. 212, Windshield Mounting

Under the test conditions of S6.1(b) in Standard No. 212, certain

tested vehicles must be loaded to their unloaded vehicle weight plus

300 pounds. In this NPRM, the agency proposes to convert 300 pounds to

136 kilograms, the exact conversion. The Canadian standards have

converted 300 pounds to the equivalent conversion of 140 kilograms. In

the conversion of 300 pounds, the concern about stringency is

particularly relevant because the manufacturers' certification testing

for Standards Nos. 208, Occupant crash protection; 212, Windshield

mounting; 219, Windshield zone intrusion; and 301, Fuel system

integrity can be conducted in a single crash test. A slight increase in

the load required for Standard No. 212 testing (resulting from a

conversion to 140 kilograms) may necessitate the manufacturers

conducting a separate crash test for Standard No. 212 certification. To

avoid this situation, the agency proposes to convert 300 pounds to the

exact conversion of 136 kilograms, rather than the equivalent

conversion of 140 kilograms.

II. Labeling Information

The agency also seeks comment on proposed metric conversions of

labels providing information to consumers. Certain FMVSSs specify

labels or wording to be placed on vehicles to provide safety

information to the consumer. At present, the FMVSSs generally specify

that labels provide units measurement in the English measurement

system. When converting the FMVSSs to the metric system, the agency is

not certain that labels incorporating metric measurements would be

informative for American consumers. Therefore, in cases where labels or

other information must be provided for the consumer's benefit, it is

proposed that the information provide both the English and metric

systems of measurement. Specifically, in converting Standard No. 120,

Tire selection and rims for motor vehicles other than passenger cars,

it is proposed that in the ``TRUCK EXAMPLE,'' the GVWR and GAWRs of a

vehicle be provided in kilograms and pounds, and the inflation pressure

of the tires be provided in kilopascals and in pounds per square inch

(psi). In Standards Nos. 120 and 110, Tire selection and rims, it is

proposed that information about the maximum speed for spare tire be

provided as ``MAXIMUM 80 KM/H (50 M.P.H.)''. In converting Standard No.

126, Truck-camper loading, it is proposed that the maximum camper

weight be provided in terms of kilograms and pounds, the capacity of

the camper be stated in terms of liters and gallons of water, the

weight of bottled gas and ice in terms of kilograms and pounds, and

refrigerator capacity (for determining vehicle weight) in terms of

cubic meters and cubic feet.

If the proposed use of dual measurements is adopted as final, the

agency anticipates, at some future date, phasing out the English units

of measurement in the consumer information labels. Public comment is

sought generally on this proposed use of dual measurements for consumer

information labels, and on the period of time after which the English

units of measurement should be phased out.

III. Force Measurements

Standards Nos. 207 and 216 establish strength requirements for

occupant seats and for the passenger compartment roof, respectively.

Standard No. 207 specifies that occupant seats shall be subjected to a

force 20 times the weight of the seat. Standard No. 216 specifies that

the vehicle roof shall be subjected to a force 1\1/2\ times the vehicle

weight. These force measurements are straightforward enough when using

units of English measurement, since both weight and force are expressed

in pounds. However, the metric system expresses mass in kilograms and

force in Newtons. Thus, in converting forces to the metric system,

there will no longer be a simple one-to-one conversion when calculating

the force that should be applied. Instead, persons conducting tests

will need to measure the weight of the seat or vehicle mass in

kilograms and multiply each figure by 9.8 to convert the figure to

Newtons. In making the metric conversion of the force measurements in

Standards Nos. 207 and 216, NHTSA proposes to specify the steps of the

conversion in the regulatory language, to minimize the chance of the

wrong metric system conversion being made. Specifically, for Standard

No. 207, NHTSA proposes to amend the force measurement language to

provide that the seat shall be subjected to a force in Newtons equal to

20 times the weight of the seat, measured in kilograms and multiplied

by 9.8. For Standard No. 216, NHTSA proposes to amend the force

measurement language to provide that the vehicle roof shall be

subjected to a force in Newtons equal to 1\1/2\ times the vehicle

weight, measured in kilograms and multiplied by 9.8. Comment is sought

on this proposal to specify the calculation of the metric force

measurement for Standards Nos. 207 and 216.

IV. Documents Incorporated by Reference

Certain standards proposed to be converted in this notice

incorporate documents that express measurements in the English system.

An example of an incorporated document is SAE Recommended Practice

J902, ``Passenger Car Windshield Defrosting Systems,'' August 1964,

parts of which are incorporated into Standard No. 103, Windshield

defrosting and defogging systems. If incorporated documents are to be

consistent with rest of the standard, some conversion of the

incorporated documents might be desirable. However, since many of the

incorporated documents are documents that are published by groups other

than NHTSA, converting these documents is an exacting and time

consuming process. The agency has decided to consider converting

incorporated documents on a case by case basis at a later date.

Regulatory Impacts

1. Executive Order 12866 and DOT Regulatory Policies and Procedures

NHTSA has examined the impact of this rulemaking action under

Executive Order 12866 and the Department of Transportation's regulatory

policies and procedures. This rulemaking document was not reviewed

under Executive Order 12866, ``Regulatory Planning and Review.'' This

action has been determined to be not ``significant'' under DOT's

regulatory policies and procedures. In converting the Federal Motor

Vehicle Safety Standards from the English to the metric measurement

system, the agency proposes conversions that would not substantively

change the performance requirements of the FMVSS's. If this rule is

made final, manufacturers now providing consumer information (e.g.,

labeling) may incur minimal additional costs since they would have to

change their information to add the metric units. However, the agency

believes additional costs would be minuscule, since manufacturers

currently label and provide consumer information in English units. The

impacts of this action would be so minor that a full regulatory

evaluation for this proposed rule has not been prepared.

2. Small Entity Impacts

The agency has also considered the effects of this rulemaking

action under the Regulatory Flexibility Act (5 U.S.C. 601 et seq.). I

certify that this proposed rule would not, if promulgated, have a

significant economic impact on a substantial number of small entities.

The rationale for this certification is that no substantive change

resulting from converting the FMVSS from the English system to the

metric system will be made to the performance requirements of any of

the Federal Motor Vehicle Safety Standards. Manufacturers that qualify

as small businesses that do not now label their products in metric

units or provide consumer information in metric units would incur some

costs to include metric labeling. However, the agency believes such

costs should be minimal, given these manufacturers are currently

labeling and providing the consumer information in English units.

3. Environmental Impacts

In accordance with the National Environmental Policy Act of 1969,

the agency has considered the environmental impacts of this proposed

rule and determined that, if adopted as a final rule, it would not have

a significant impact on the quality of the human environment.

4. Federalism

This action has been analyzed in accordance with the principles and

criteria contained in Executive Order 12612, and it has been determined

that the proposed rulemaking does not have sufficient federalism

implications to warrant the preparation of a Federalism Assessment.

5. Civil Justice Reform

This proposed rule would not have a retroactive effect. Under

section 103(d) of the National Traffic and Motor Vehicle Safety Act (15

U.S.C. 1392(D)), whenever a Federal motor vehicle safety standard is in

effect, a state may not adopt or maintain a safety standard applicable

to the same aspect of performance which is not identical to the Federal

standard. Section 105 of the Act (15 U.S.C. 1394) sets forth a

procedure for judicial review of final rules establishing, amending or

revoking Federal motor vehicle safety standards. That section does not

require submission of a petition for reconsideration or other

administrative proceedings before parties may file suit in court.

Public Comments

Interested persons are invited to submit comments on the proposal.

It is requested, but not required, that 10 copies be submitted.

All comments must not exceed 15 pages in length. (49 CFR 553.21).

Necessary attachments may be appended to these submissions without

regard to the 15-page limit. This limitation is intended to encourage

commenters to detail their primary arguments in a concise fashion.

If a commenter wishes to submit certain information under a claim

of confidentiality, three copies of a complete submission, including

purportedly confidential business information, should be submitted to

the Chief Counsel, NHTSA, at the street address given above, and seven

copies from which the purportedly confidential information has been

deleted should be submitted to the Docket Section. A request for

confidentiality should be accompanied by a cover letter setting forth

the information specified in the agency's confidential business

information regulation. 49 CFR part 512.

All comments received before the close of business on the comment

closing date indicated above for the proposal will be considered, and

will be available for examination in the docket at the above address

both before and after the date. To the extent possible, comments filed

after the closing date will also be considered. Comments received too

late for consideration in regard to the final rule will be considered

as suggestions for further rulemaking action. Comments on the proposal

will be available for inspection in the docket. The NHTSA will continue

to file relevant information as it becomes available in the docket

after the closing date, and it is recommended that interested persons

continue to examine the docket for new material.

Those persons desiring to be notified upon receipt of their

comments in the rules docket should enclose a self-addressed, stamped

postcard in the envelope with their comments. Upon receiving the

comments, the docket supervisor will return the postcard by mail.

List of Subjects in 49 CFR Part 571

Imports, Motor vehicle safety, Motor vehicles, Rubber and rubber

products, Tires.

In consideration of the foregoing, it is proposed that the Federal

Motor Vehicle Standards (49 CFR part 571 be amended as set forth below.

PART 571--FEDERAL MOTOR VEHICLE SAFETY STANDARDS

1. The authority citation for part 571 would continue to read as

follows:

Authority: 15 U.S.C. 1392, 1401, 1403, 1407; delegation of

authority at 49 CFR 1.50.

2. Section 571.102 would be amended by revising S1, and revising

S3.1.2, to read as follows:

Sec. 571.102 Standard No. 102, Transmission shift lever sequence,

starter interlock, and transmission braking effect.

S1. Purpose and scope. This standard specifies the requirements for

the transmission shift lever sequence, a starter interlock, and for a

braking effect of automatic transmissions, to reduce the likelihood of

shifting errors, starter engagement with vehicle in drive position, and

to provide supplemental braking at speeds below 40 kilometers per hour.

* * * * *

S3.1.2 Transmission braking effect. In vehicles having more than

one forward transmission gear ratio, one forward drive position shall

provide a greater degree of engine braking than the highest speed

transmission ratio at vehicle speeds below 40 kilometers per hour.

* * * * *

3. Section 571.103 would be amended by revising S3; and, in S4.3,

revising paragraphs (b)(ii), (e), (g), and (h), to read as follows:

Sec. 571.103 Standard No. 103, Windshield defrosting and defogging

systems.

* * * * *

S3. Definitions. Road load means the power output required to move

a given motor vehicle at curb weight plus 180 kilograms on level,

clean, dry, smooth portland cement concrete pavement (or other surface

with equivalent coefficient of surface friction) at a specified speed

through still air at 20 degrees Celsius, and standard barometric

pressure (101.3 kilopascals) and includes driveline friction, rolling

friction, and air resistance.

* * * * *

S4.3 * * *

(b) * * *

(ii) The engine speed and load shall not exceed the speed and load

at 40 kilometers per hour in the manufacturer's recommended gear with

road load.

* * * * *

(e) One or two windows may be open a total of 25 millimeters:

(g) The wind velocity is at any level from 0 to 3 kilometers per

hour.

(h) The test chamber temperature and the wind velocity shall be

measured, after the engine has been started, at the forwardmost point

of the vehicle or a point 914 millimeters from the base of the

windshield, whichever is farther forward, at a level halfway between

the top and bottom of the windshield on the vehicle centerline.

4. Section 571.104 would be amended by revising, in S3, the

definition ``Glazing surface reference line''; and revising S4.1.2, to

read as follows:

Sec. 571.104 Standard No. 104, Windshield wiping and washing systems.

* * * * *

S3 * * *

Glazing surface reference line means the line resulting from the

intersection of the glazing surface and a horizontal plane 625

millimeters above the seating reference point, as shown in Figure 1 of

SAE Recommended Practice J903a, ``Passenger Car Windshield Wiper

Systems,'' May 1966.

* * * * *

S4.1.2 Wiped area. When tested wet in accordance with SAE

Recommended Practice J903a, May 1966, each passenger car windshield

wiping system shall wipe the percentage of Areas A, B, and C of the

windshield (established in accordance with S4.1.2.1) that (1) is

specified in column 2 of the applicable table following paragraph

S4.1.2.1 and (2) is within the area bounded by a perimeter line on the

glazing surface 25 millimeters from the edge of the daylight opening.

* * * * *

5. In Sec. 571.104, S4.1.2.1 would be amended by revising the title

of Table I; the title of Table II; the title of Table III; and the

title of Table IV, to read as follows:

* * * * *

Table I--Passenger Cars of Less Than 1520 Millimeters in Overall Width

* * * * *

Table II--Passenger Cars of 1520 or More But Less Than 1630 Millimeters

in Overall Width

* * * * *

Table III--Passenger Cars of 1630 or More But Less Than 1730

Millimeters in Overall Width

* * * * *

Table IV--Passenger Cars of 1730 or More Millimeters in Overall Width

* * * * *

6. Section 571.110 would be amended by revising, in S3, the

definitions ``Normal occupant weight,'' ``Production options weight,''

and ``Vehicle capacity weight''' in S4.4.1, revising paragraph (b); in

S6, revising the introductory paragraph, and paragraph (b); and

revising S7.1, to read as follows:

Sec. 571.110 Standard No. 110, Tire Selection and rims.

* * * * *

S3 * * *

Normal occupant weight means 68 kilograms times the number of

occupants specified in the second column of Table I.

* * * * *

Production options weight means the combined weight of those

installed regular production options weighing over 2.3 kilograms in

excess of those standard items which they replace, not previously

considered in curb weight or accessory weight, including heavy duty

brakes, ride levelers, roof rack, heavy duty battery, and special trim.

* * * * *

Vehicle capacity weight means the rated cargo and luggage load plus

68 kilograms times the vehicle's designated seating capacity.

* * * * *

S4.4.1 * * *

(b) In the event of rapid loss of inflation pressure with the

vehicle traveling in a straight line at a speed of 97 kilometers per

hour, retain the deflated tire until the vehicle can be stopped with a

controlled braking application.

* * * * *

S6 Labeling Requirements for Non-Pneumatic Spare Tires or Tire

Assemblies.

Each non-pneumatic tire or, in the case of a non-pneumatic tire

assembly in which the non-pneumatic tire is an integral part of the

assembly, each non-pneumatic tire assembly shall include, in letters or

numerals not less than 4 millimeters high, the information specified in

paragraphs S6 (a) and (b). The information shall be permanently molded,

stamped, or otherwise permanently marked into or onto the non-pneumatic

tire or non-pneumatic tire assembly, or shall appear on a label that is

permanently attached to the tire or tire assembly. If a label is used,

it shall be subsurface printed, made of material that is resistant to

fade, heat, moisture and abrasion, and attached in such a manner that

it cannot be removed without destroying or defacing the label on the

non-pneumatic tire or tire assembly. The information specified in

paragraphs S6 (a) and (b) shall appear on both sides of the non-

pneumatic tire or tire assembly, except, in the case of a non-pneumatic

tire assembly which has a particular side that must always face outward

when mounted on a vehicle, in which case the information specified in

paragraphs S6 (a) and (b) shall only be required on the outward facing

side. The information shall be positioned on the tire or tire assembly

such that it is not placed on the tread or the outermost edge of the

tire and is not obstructed by any portion of any non-pneumatic rim or

wheel center member designated for use with that tire in this standard

or in Standard No. 129.

* * * * *

(b) MAXIMUM 80 KM/H (50 M.P.H.)

* * * * *

S7.1 Vehicle Placarding Requirements. A placard, permanently

affixed to the inside of the vehicle trunk or an equally accessible

location adjacent to the non-pneumatic spare tire assembly, shall

display the information set forth in S6 in block capitals and numerals

not less than 6 millimeters high preceded by the words ``IMPORTANT--USE

OF SPARE TIRE'' in letters not less than 9 millimeters high.

* * * * *

7. Section 571.112 would be amended by revising S4.5 to read as

follows:

Sec. 571.112 Standard No. 112, Headlamp concealment devices.

* * * * *

S4.5 Except for cases of malfunction covered by S4.2, each

headlamp concealment device shall, within an ambient temperature range

of -30 degrees Celsius to +50 degrees Celsius be capable of being fully

opened in not more than 3 seconds after actuation of the mechanism

described in S4.3.

8. Section 571.114 would be amended by revising 32 and revising

S4.1, to read as follows:

Sec. 571.114 Standard No. 114, Theft protection.

* * * * *

S2 Application. This standard applies to passenger cars, and to

trucks and multipurpose passenger vehicles having a GVWR of 4536

kilograms or less. However, it does not apply to walk-in van-type

vehicles.

* * * * *

S4.1 Each truck and multipurpose passenger vehicle having a GVWR

of 4536 kilograms or less manufactured on or after September 1, 1983

and each passenger car shall meet the requirements of S4.2, S4.3, S4.4,

and S4.5. However, open-body type vehicles that are manufactured for

operation without doors and that either have no doors or have doors

that are designed to be easily attached to and removed from the vehicle

by the vehicle owner are not required to comply with S4.5.

* * * * *

9. Section 571.115 would be amended by revising S4.6 to read as

follows:

Sec. 571.115 Standard No. 115, Vehicle identification number--basic

requirements.

* * * * *

S4.6 This VIN for passenger cars, multipurpose passenger vehicles,

and trucks of 4536 kilograms or less GVWR shall be located inside the

passenger compartment. It shall be readable, without moving any part of

the vehicle, through the vehicle glazing under daylight lighting

conditions by an observer having 20/20 vision (Snellen) whose eye-point

is located outside the vehicle adjacent to the left windshield pillar.

Each character in the VIN subject to this paragraph shall have a

minimum height of 4 mm.

* * * * *

10. Section 571.118 would be amended by revising S2. to read as

follows:

Sec. 571.118 Standard No. 118, Power-operated window, partition, and

roof panel systems.

* * * * *

S2. Application. This standard applies to passenger cars,

multipurpose passenger vehicles, and trucks with a gross vehicle weight

rating of 4536 kilograms or less. The standard's requirements for

power-operated roof panel systems need not be met for vehicles

manufactured before September 1, 1993.

* * * * *

11. Section 571.120 would be amended by revising the first sentence

in S5.1.2; revising in S5.2, the introductory paragraph; revising in

S5.3, the introductory paragraph; revising S5.3.2; revising in S7, the

introductory paragraph and paragraph (b); and revising S8.1, to read as

follows:

Sec. 571.120 Standard No. 120, Tire selection and rims for motor

vehicles other than passenger cars.

* * * * *

S5.1.2 Except in the case of a vehicle which has a speed

attainable in 3.2 kilometers of 80 kilometers per hour or less, the sum

of the maximum load ratings of the tires fitted to an axle shall be not

less than the gross axle weight rating (GAWR) of the axle system as

specified on the vehicle's certification label required by 49 CFR part

567. * * *

* * * * *

S5.2 Rim marking. On and after August 1, 1977, each rim or, at the

option of the manufacturer in the case of a singlepiece wheel, wheel

disc shall be marked with the information listed in paragraphs (a)

through (e) of this paragraph, in lettering not less than 3 millimeters

high, impressed to a depth or, at the option of the manufacturer,

embossed to a height of not less than 0.125 millimeters. The

information listed in paragraphs (a) through (c) of this paragraph

shall appear on the weather side. In the case of rims of multipiece

construction, the information listed in paragraphs (a) through (e) of

this paragraph shall appear on the rim base and the information listed

in paragraphs (b) and (d) of this paragraph shall also appear on each

other part of the rim.

* * * * *

S5.3 Label information. Each vehicle manufactured on or after

December 1, 1984, shall show the information specified in S5.3.1 and

S5.3.2, and in the case of a vehicle equipped with a non-pneumatic

spare tire, the information specified in S5.3.3, in the English

language, lettered in block capitals and numerals not less than 2.4

millimeters high and in the format set forth following this section.

This information shall appear either--

* * * * *

S5.3.2. Rims. The size designation and, if applicable, the type

designation of Rims (not necessarily those on the vehicle) appropriate

for those tires.

Truck Example

SUITABLE TIRE-RIM CHOICE

GVWR: 7,840 kilograms (17,280 pounds)

GAWR: Front--2,850 kilograms (6,280 pounds) with 7.50--20(D) tires,

20 x 6.00 rims at 520 kPa (75 psi) cold single

GAWR: Rear--4,990 kilograms (11,000 pounds) with 7.50--29-(D) tires,

20 x 6.00 rims, at 450 kPa (65 psi) cold dual

GAWR: 13,280 kilograms (29,279 pounds)

GAWR: Front--4,826 kilograms (10,640 pounds) with 10.00--20(F) tires,

20 x 7.50 rims, at 620 kPa (90 psi) cold single

GAWR: Rear--8,454 kilograms (18,639 pounds) with 10.00--20(F) tires,

20 x 7.50 rims, at 550 kPa (80 psi) cold dual

* * * * *

S7 Labeling Requirements for Non-Pneumatic Spare Tires or Tire

Assemblies. Each non-pneumatic tire or, in the case of a non-pneumatic

tire assembly in which the non-pneumatic tire is an integral part of

the assembly, each non-pneumatic tire assembly shall include, in

letters or numerals not less than 4 millimeters high, the information

specified in paragraphs S7 (a) and (b). The information shall be

permanently molded, stamped, or otherwise permanently marked into or

onto the non-pneumatic tire or non-pneumatic tire assembly, or shall

appear on a label that is permanently attached to the tire or tire

assembly. If a label is used, it shall be subsurface printed, made of

material that is resistant to fade, heat, moisture and abrasion, and

attached in such a manner that it cannot be removed without destroying

or defacing the label on the non-pneumatic tire or tire assembly. The

information specified in paragraphs S7 (a) and (b) shall appear on both

sides of the non-pneumatic tire or tire assembly, except, in the case

of a non-pneumatic tire-assembly which has a particular side that must

always face outward when mounted on a vehicle, in which case the

information specified in paragraphs S7 (a) and (b) shall only be

required on the outward facing side. The information shall be

positioned on the tire or tire assembly such that it is not placed on

the tread or the outermost edge of the tire and is not obstructed by

any portion of any non-pneumatic rim or wheel center member designated

for use with that tire in this standard or in Standard No. 129.

* * * * *

(b) MAXIMUM 80 KM/H (50 M.P.H.).

* * * * *

S8.1 Vehicle Placarding Requirements. A placard, permanently

affixed to the inside of the space tire stowage area or equally

accessible location adjacent to the non-pneumatic spare tire assembly,

shall display the information set forth in S7 in block capitals and

numerals not less than 6 millimeters high preceded by the words

``IMPORTANT--USE OF SPARE TIRE'' in letters not less than 9 millimeters

high.

* * * * *

12. Section 571.124 is amended by revising S5 and revising S5.3 to

read as follows:

Sec. 571.124 Standard No. 124, Accelerator control systems.

* * * * *

S5. Requirements. The vehicle shall meet the following requirements

when the engine is running under any load condition, and at any ambient

temperature between -40 degrees Celsius and +52 degrees Celsius after

12 hours of conditioning at any temperature within that range.

* * * * *

S5.3 (a) Except as provided in paragraph (b), maximum time to

return to idle position shall be 1 second for vehicles of 4536

kilograms or less GVWR, and 2 seconds for vehicles of more than 4536

kilograms GVWR. (b) Maximum time to return to idle position shall be 3

seconds for any vehicle that is exposed to ambient air at -18 degrees

Celsius to -40 degrees Celsius during the test or for any portion of

the 12-hour conditioning period.

13. Section 571.126 is amended by revising in S4, the paragraph

titled ``Cargo weight rating''; revising in S5.1.1, the introductory

paragraph and paragraph (d); and revising in S5.1.2, paragraphs (b) and

(e), to read as follows:

Sec. 571.126 Standard No. 126, Truck-camper loading.

* * * * *

S4. * * *

Cargo weight rating means the value specified by the manufacturer

as the cargo-carrying capacity, in pounds and kilograms, of a vehicle,

exclusive of the weight of occupants in designated seating positions.

* * * * *

S5.1.1 Labels. Each slide-in camper shall have permanently affixed

to it, in a manner that it cannot be removed without defacing or

destroying it, in a plainly visible location on an exterior rear

surface other than the roof, steps, or bumper extension, a label

containing the following information in the English language lettered

in block capitals and numerals not less than 2.4 millimeters high, or a

color contrasting with the background, and in the order shown below and

in the form illustrated in Figure 1.

* * * * *

(d) The following statement completed as appropriate:

``Camper weight is ____ Kgs. (____ Lbs.) Maximum When it Contains

Standard Equipment, ____ Liters (____ Gal.) of Water, ____ Kgs. (____

Lbs.) of Bottled Gas, and ____ Cubic Meters (____ Ft.) Refrigerator (or

Icebox with ____ Kgs. (____ Lbs.) of Ice, as applicable). Consult

Owner's Manual (or Data Sheet as applicable) for Weights of Additional

or Optional Equipment.''

``Liters and Gals. of water'' refer to the volume of water

necessary to fill the camper's fresh water tanks to capacity. ``Kgs.

and Lbs. of Bottled Gas'' refer to the weight of the gas necessary to

fill the camper's bottled gas tanks to capacity. The statement

regarding a ``Refrigerator'' or Icebox'' refers to the capacity of the

refrigerator with which the vehicle is equipped or the weight of the

ice with which the icebox may be filled. Any of these items may be

omitted from the statement, if the corresponding accessories are not

included with the camper, provided that the omission is noted in the

camper owner's manual as required in paragraph S5.1.2(a).

* * * * *

S5.1.2 * * *

(b) A list of other additional or optional equipment that the

camper is designed to carry, and the maximum weight of each if its

weight is more than 9 kilograms when installed.

* * * * *

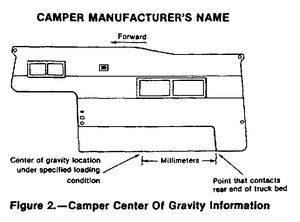

(e) A picture showing the location of the longitudinal center of

gravity of the camper within an accuracy of 50 millimeters under the

loaded condition specified in paragraph S5.1.1(d), in the manner

illustrated in Figure 2. Until October 1, 1973, the phrase ``Mount at

Aft End of Truck Cargo Area'' may be used in Figure 2 instead of

``Point That Contacts Rear End of Truck Bed.''

* * * * * *

14. Section 571.126 would be amended by revising Figure 1 at the

end of the introductory paragraph in S5.1.1 to read as follows:

MFD. BY: (CAMPER MANUFACTURER'S NAME)

(MONTH AND YEAR OF MANUFACTURE)

THIS CAMPER CONFORMS TO ALL APPLICABLE FEDERAL MOTOR VEHICLE SAFETY

STANDARDS IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE

CAMPER WEIGHT IS ____KG (____LBS.) MAXIMUM WHEN IT CONTAINS STANDARD

EQUIPMENT, ____LTRS. (____GAL.) OF WATER, ____KG. (____LBS.) OF

BOTTLED GAS, AND ____ CUBIC METERS (____ CUBIC FT.) REFRIGERATOR (OR

ICEBOX WITH ____KG (____LBS.) OF ICE, AS APPLICABLE). CONSULT

OWNER'S MANUAL (OR DATA SHEET AS APPLICABLE) FOR WEIGHTS OF

ADDITIONAL OR OPTIONAL EQUIPMENT.

(VEHICLE IDENTIFICATION NUMBER)

Figure 1. Label for Campers

15. In Sec. 571.126, Figure 2 at S5.1.1, after the introductory

paragraph, would be revised to read as follows:

16. Section 571.205 would be amended by revising in S5.1.1.2,

paragraph (m); revising S5.1.1.5; revising in S5.1.2.2, paragraph (b);

revising in S5.1.2.3, paragraph (b); revising in S5.1.2.9, paragraph

(b); and revising in S5.1.2.10, paragraph (b), to read as follows:

Sec. 571.205 Standard No. 205, Glazing materials.

* * * * *

S5.1.1.2 * * *

(m) For Item 5 safety glazing only: Motorcycle windscreens below

the intersection of a horizontal plane 380 millimeters vertically above

the lowest seating position.

* * * * *

S5.1.1.5 The phrase ``readily removable'' windows as defined in

ANS Z26, for the purposes of this standard, in buses having a GVWR of

more than 4536 kilograms, shall include pushout windows and windows

mounted in emergency exits that can be manually pushed out of their

location in the vehicle without the use of tools, regardless of whether

such windows remain hinged at one side to the vehicle.

S5.1.2.2 * * *

(b) Motorcycle windscreens below the intersection of a horizontal

plane 380 millimeters vertically above the lowest seating position.

* * * * *

S5.1.2.3 * * *

(b) Motorcycle windscreens below the intersection of a horizontal

plane 380 millimeters vertically above the lowest seating position.

* * * * *

S5.1.2.9 * * *

(b) Glass-plastic specimens shall be exposed to an ambient air

temperature of -40 degrees Celsius (plus or minus 5 degrees Celsius),

for a period of 6 hours at the commencement of Test No. 28, rather than

at the initial temperature specified in that test. After testing, the

glass-plastic specimens shall show no evidence of cracking, clouding,

delaminating, or other evidence of deterioration.

* * * * *

S5.1.2.10 * * *

(b) Each manufacturer of glazing materials designed to meet the

requirements of paragraphs S5.1.2.4, S5.1.2.5, S5.1.2.6, S5.1.2.7, or

S5.1.2.8 may permanently and indelibly mark the lower center of each

item of such glazing material, in letters not less than 4.5 millimeters

nor more than 6 millimeters high, the following words, GLASS PLASTIC

MATERIAL--SEE OWNER'S MANUAL FOR CARE INSTRUCTIONS.

* * * * *

17. Section 571.206 would be amended by revising S4.1.1.1; revising

S4.1.1.2; revising S4.1.2; revising S4.2.1.1; revising S4.2.1.2;

revising S4.2.2; revising S4.3; and revising S5.3, to read as follows:

Sec. 571.206 Standard No. 206, Door locks and door retention

components.

* * * * *

S4.1.1.1 Longitudinal Load. The door latch and striker assembly,

when in the fully latched position, shall not separate when a

longitudinal load of 11,120 Newtons is applied. When in the secondary

latch position, the door latch and striker assembly shall not separate

when a longitudinal load of 4,450 Newtons is applied.

S4.1.1.2 Transverse Load. The door latch and striker assembly,

when in the fully latched position, shall not separate when a

transverse load of 8,900 Newtons is applied. When in the secondary

latched position, the door latch and striker assembly shall not

separate when a transverse load of 4,450 Newtons is applied.

* * * * *

S4.1.2. Door Hinges. Each door hinge system shall support the door

and shall not separate when a longitudinal load of 11,120 Newtons is

applied. Similarly, each door hinge system shall not separate when a

transverse load of 8,900 Newtons is applied.

* * * * *

S4.2.1.1 Longitudinal Load. Each latch system, when in the latched

position, shall not separate when a longitudinal load of 11,120 Newtons

is applied.

S4.2.1.2 Transverse Load. Each latch system, when in the latched

position, shall not separate when a transverse load of 8,900 Newtons is

applied. When more than one latch system is used on a single door, the

load requirement may be divided among the total number of latch

systems.

S4.2.2 Door Hinges. Each door hinge system shall support the door

and shall not separate when a longitudinal load of 11,120 Newtons is

applied, and when a transverse load of 8,900 Newtons is applied.

S4.3 Sliding Doors. The track and slide combination or other

supporting means for each sliding door shall not separate when a total

transverse load of 17,800 Newtons is applied, with the door in the

closed position.

* * * * *

S5.3 Sliding Doors. Compliance with S4.3 shall be demonstrated by

applying an outward transverse load of 8,900 Newtons to the load

bearing members at the opposite edges of the door (17,800 Newtons

total). The demonstration may be performed either in the vehicle or

with the door retention components in a bench test fixture.

18. Section 571.207 would be amended by revising in S4.2, the

introductory paragraph, paragraph (a), paragraph (b), and paragraph

(d); revising S4.3.2.1; and revising S5.1.2, to read as follows:

Sec. 571.207 Standard No. 207, Seating systems.

* * * * *

S.4.2 General performance requirements. When tested in accordance

with S5., each occupant seat, other than a side-facing seat or a

passenger seat on a bus, shall withstand the following forces, in

Newtons.

(a) In any position to which it can be adjusted--20 times the

weight of the seat in kilograms multiplied by 9.8 applied in a forward

longitudinal direction;

(b) In any position to which it can be adjusted--20 times the

weight of the seat applied in kilograms multiplied by 9.8 in a rearward

longitudinal direction;

* * * * *

(d) In its rearmost position--a force that produces a 373 Newton

meters moment about the seating reference point for each designated

seating position that the seat provides, applied to the upper cross-

member of the seat back or the upper seat back, in a rearward

longitudinal direction for forward-facing seats and in a forward

longitudinal direction for rearward-facing seats.

* * * * *

S4.3.2.1 Static force.

(a) Once engaged, the restraining device for a forward-facing seat

shall not release or fail when a forward longitudinal force, in

Newtons, equal to 20 times the weight of the hinged or folding portion

of the seat in kilograms multiplied by 9.8 is applied through the

center of gravity of that portion of the seat.

(b) Once engaged, the restraining device for a forward-facing seat

shall not release or fail when a forward longitudinal force, in

Newtons, equal to 8 times the weight of the hinged or folding portion

of the seat in kilograms multiplied by 9.8 is applied through the

center of gravity of that portion of the seat.

* * * * *

S5.1.2 If the seat back and the seat bench are attached to the

vehicle by different attachments, attach to each component a fixture

capable of transmitting a force to that component. Apply forces, in

Newtons, equal to 20 times the weight of the seat in kilograms

multiplied by 9.8 horizontally through the center of gravity of the

seat back, as shown in Figure 2 and apply forces, in Newtons, equal to

20 times the weight of the seat in kilograms multiplied by 9.8

horizontally through the center of gravity of the seat bench, as shown

in Figure 3.

* * * * *

19. Section 571.212 would be amended by revising S3; revising S5;

revising in S6.1, paragraph (b); and revising S6.5, to read as follows:

Sec. 571.212 Standard No. 212, Windshield mounting.

* * * * *

S3. Application. This standard applies to passenger cars, and to

multipurpose passenger vehicles, trucks, and buses having a gross

vehicle weight rating of 4536 kilograms or less. However, it does not

apply to forward control vehicles, walk-in van-type vehicles, or to

open-body type vehicles with fold-down or removable windshields.

* * * * *

S5. Requirements. When the vehicle travelling longitudinally

forward at any speed up to and including 48 kilometers per hour impacts

a fixed collision barrier that is perpendicular to the line of travel

of the vehicle, under the conditions of S6, the windshield mounting of

the vehicle shall retain not less than the minimum portion of the

windshield periphery specified in S5.1 and S5.2.

S6.1 * * *

(b) Except as specified in S6.2, a multipurpose passenger vehicle,

truck or bus is loaded to its unloaded vehicle weight, plus 136

kilograms or its rated cargo and luggage capacity, whichever is less,

secured to the vehicle, plus a 50th-percentile test dummy as specified

in part 572 of this chapter at each from outboard designated seating

position and at any other position whose protection system is required

to be tested by a dummy under the provisions of Standard No. 208. Each

dummy is restrained only by means that are installed for protection at

its seating position. The load is distributed so that the weight on

each axle as measured at the tire-ground interface is in proportion to

its GAWR. If the weight on any axle when the vehicle is loaded to its

unloaded vehicle weight plus dummy weight exceeds the axle's

proportional share of the test weight, the remaining weight is placed

so that the weight on that axle remains the same. For the purposes of

this section, unloaded vehicle weight does not include the weight of

work-performing accessories. Vehicles are tested to a maximum unloaded

vehicle weight of 2.495 kilograms.

* * * * *

S6.5 The windshield mounting material and all vehicle components in

direct contact with the mounting material are at any temperature

between -93 degrees Celsius and +43 degrees Celsius.

20. Section 571.216 would be amended by revising S3; revising S4;

revising S5; revising in S6.2, paragraph (d); and revising S6.3 to read

as follows:

Sec. 571.216 Standard No. 216, Roof crush resistance--passenger cars.

* * * * *

S3. Application. This standard applies to passenger cars, and to

multipurpose passenger vehicles, trucks and buses with a GVWR of 2722

kilograms or less. However, it does not apply to--

(a) School buses;

(b) Vehicles that conform to the rollover test requirements (S5.3)

of Standard No. 208 (Sec. 571.208) by means that require no action by

vehicle occupants; or

(c) Convertibles, except for optional compliance with the standard

as an alternative to the rollover test requirements in S5.3 of Standard

No. 208.

S4. Requirements--(a) Passenger cars. A test device as described in

S5 shall not move more than 125 millimeters, measured in accordance

with S6.4, when it is used to apply a force in Newtons equal to 1\1/2\

times the unloaded vehicle weight of the vehicle, measured in kilograms

and multiplied by 9.8 or 22,240 Newtons, whichever is less, to either

side of the forward edge of a vehicle's roof in accordance with the

procedures of S6. Both the left and right front portions of the

vehicle's roof structure shall be capable of meeting the requirements,

but a particular vehicle need not meet further requirements after being

tested at one location.

(b) Multipurpose passenger vehicles, trucks and buses with a GVWR

of 2,722 kilograms or less, manufactured on or after September 1, 1994.

For multipurpose passenger vehicles, trucks and buses with a GVWR of

2,722 kilograms or less, manufactured on or after September 1, 1994, a

test device as described in S5 shall not move more than 125

millimeters, measured in accordance with S6.4, when it is used to apply

a force in Newtons equal to 1 \1/2\ times the unloaded vehicle weight

of the vehicle, measured in kilograms and multiplied by 9.8, to either

side of the forward edge of a vehicle's roof in accordance with the

procedures of S6. Both the left and right front portions of the

vehicles's roof structure shall be capable of meeting the requirements,

but a particular vehicle need not meet further requirements after being

tested at one location.

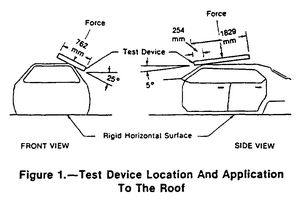

S5. Test device. The test device is a rigid unyielding block with

its lower surface formed as a flat rectangle 762 millimeters x 1829

millimeters.

* * * * *

S6.2 * * *

(d) The initial contact point, or center of the initial contact

area, is on the longitudinal centerline of the lower surface of the

test device and 254 millimeters from the forwardmost point of that

centerline.

6.3 (a) Passenger cars. Apply force in a downward direction

perpendicular to the lower surface of the test device at a rate of not

more than 13 millimeters per second until reaching a force in Newtons

of 1\1/2\ times the unloaded vehicle weight of the tested vehicle,

measured in kilograms and multiplied by 9.8 or 22,240 Newtons,

whichever is less. Complete the test within 120 seconds. Guide the test

device so that throughout the test it moves, without rotation, in a

straight line with its lower surface oriented as specified in S6.2(a)

through S6.2(d).

(b) Multipurpose passenger vehicles, trucks and buses with a GVWR

of 2,722 kilograms or less, manufactured on or after September 1, 1994.

For multipurpose passenger vehicles, trucks and buses with a GVWR of

2,722 kilograms or less, manufactured on or after September 1, 1994,

apply force in a downward direction perpendicular to the lower surface

of the test device at a rate of not more than 13 millimeters per second

until reaching a force in Newtons of 1\1/2\ times the unloaded vehicle

weight of the tested vehicle, measured in kilograms and multiplied by

9.8. Complete the test within 120 seconds. Guide the test device so

that throughout the test it moves, without rotation, in a straight line

with its lower surface oriented as specified in S6.2(a) through

S6.2(d).

* * * * *

21. Section 571.216, would be amended by revising Figure 1 at the

end of the S6.4 to read as follows:

16. Section 571.205 would be amended by revising in S5.1.1.2,

paragraph (m); revising S5.1.1.5; revising in S5.1.2.2, paragraph (b);

revising in S5.1.2.3, paragraph (b); revising in S5.1.2.9, paragraph

(b); and revising in S5.1.2.10, paragraph (b), to read as follows:

Sec. 571.205 Standard No. 205, Glazing materials.

* * * * *

S5.1.1.2 * * *

(m) For Item 5 safety glazing only: Motorcycle windscreens below

the intersection of a horizontal plane 380 millimeters vertically above

the lowest seating position.

* * * * *

S5.1.1.5 The phrase ``readily removable'' windows as defined in

ANS Z26, for the purposes of this standard, in buses having a GVWR of

more than 4536 kilograms, shall include pushout windows and windows

mounted in emergency exits that can be manually pushed out of their

location in the vehicle without the use of tools, regardless of whether

such windows remain hinged at one side to the vehicle.

S5.1.2.2 * * *

(b) Motorcycle windscreens below the intersection of a horizontal

plane 380 millimeters vertically above the lowest seating position.

* * * * *

S5.1.2.3 * * *

(b) Motorcycle windscreens below the intersection of a horizontal

plane 380 millimeters vertically above the lowest seating position.

* * * * *

S5.1.2.9 * * *

(b) Glass-plastic specimens shall be exposed to an ambient air

temperature of -40 degrees Celsius (plus or minus 5 degrees Celsius),

for a period of 6 hours at the commencement of Test No. 28, rather than

at the initial temperature specified in that test. After testing, the

glass-plastic specimens shall show no evidence of cracking, clouding,

delaminating, or other evidence of deterioration.

* * * * *

S5.1.2.10 * * *

(b) Each manufacturer of glazing materials designed to meet the

requirements of paragraphs S5.1.2.4, S5.1.2.5, S5.1.2.6, S5.1.2.7, or

S5.1.2.8 may permanently and indelibly mark the lower center of each

item of such glazing material, in letters not less than 4.5 millimeters

nor more than 6 millimeters high, the following words, GLASS PLASTIC

MATERIAL--SEE OWNER'S MANUAL FOR CARE INSTRUCTIONS.

* * * * *

17. Section 571.206 would be amended by revising S4.1.1.1; revising

S4.1.1.2; revising S4.1.2; revising S4.2.1.1; revising S4.2.1.2;

revising S4.2.2; revising S4.3; and revising S5.3, to read as follows:

Sec. 571.206 Standard No. 206, Door locks and door retention

components.

* * * * *

S4.1.1.1 Longitudinal Load. The door latch and striker assembly,

when in the fully latched position, shall not separate when a

longitudinal load of 11,120 Newtons is applied. When in the secondary

latch position, the door latch and striker assembly shall not separate

when a longitudinal load of 4,450 Newtons is applied.

S4.1.1.2 Transverse Load. The door latch and striker assembly,

when in the fully latched position, shall not separate when a

transverse load of 8,900 Newtons is applied. When in the secondary

latched position, the door latch and striker assembly shall not

separate when a transverse load of 4,450 Newtons is applied.

* * * * *

S4.1.2. Door Hinges. Each door hinge system shall support the door

and shall not separate when a longitudinal load of 11,120 Newtons is

applied. Similarly, each door hinge system shall not separate when a

transverse load of 8,900 Newtons is applied.

* * * * *

S4.2.1.1 Longitudinal Load. Each latch system, when in the latched

position, shall not separate when a longitudinal load of 11,120 Newtons

is applied.

S4.2.1.2 Transverse Load. Each latch system, when in the latched

position, shall not separate when a transverse load of 8,900 Newtons is

applied. When more than one latch system is used on a single door, the

load requirement may be divided among the total number of latch

systems.

S4.2.2 Door Hinges. Each door hinge system shall support the door

and shall not separate when a longitudinal load of 11,120 Newtons is

applied, and when a transverse load of 8,900 Newtons is applied.

S4.3 Sliding Doors. The track and slide combination or other

supporting means for each sliding door shall not separate when a total

transverse load of 17,800 Newtons is applied, with the door in the

closed position.

* * * * *

S5.3 Sliding Doors. Compliance with S4.3 shall be demonstrated by

applying an outward transverse load of 8,900 Newtons to the load

bearing members at the opposite edges of the door (17,800 Newtons

total). The demonstration may be performed either in the vehicle or

with the door retention components in a bench test fixture.

18. Section 571.207 would be amended by revising in S4.2, the

introductory paragraph, paragraph (a), paragraph (b), and paragraph

(d); revising S4.3.2.1; and revising S5.1.2, to read as follows:

Sec. 571.207 Standard No. 207, Seating systems.

* * * * *

S.4.2 General performance requirements. When tested in accordance

with S5., each occupant seat, other than a side-facing seat or a

passenger seat on a bus, shall withstand the following forces, in

Newtons.

(a) In any position to which it can be adjusted--20 times the

weight of the seat in kilograms multiplied by 9.8 applied in a forward

longitudinal direction;

(b) In any position to which it can be adjusted--20 times the

weight of the seat applied in kilograms multiplied by 9.8 in a rearward

longitudinal direction;

* * * * *

(d) In its rearmost position--a force that produces a 373 Newton

meters moment about the seating reference point for each designated

seating position that the seat provides, applied to the upper cross-

member of the seat back or the upper seat back, in a rearward

longitudinal direction for forward-facing seats and in a forward

longitudinal direction for rearward-facing seats.

* * * * *

S4.3.2.1 Static force.

(a) Once engaged, the restraining device for a forward-facing seat

shall not release or fail when a forward longitudinal force, in

Newtons, equal to 20 times the weight of the hinged or folding portion

of the seat in kilograms multiplied by 9.8 is applied through the

center of gravity of that portion of the seat.

(b) Once engaged, the restraining device for a forward-facing seat

shall not release or fail when a forward longitudinal force, in

Newtons, equal to 8 times the weight of the hinged or folding portion

of the seat in kilograms multiplied by 9.8 is applied through the

center of gravity of that portion of the seat.

* * * * *

S5.1.2 If the seat back and the seat bench are attached to the

vehicle by different attachments, attach to each component a fixture

capable of transmitting a force to that component. Apply forces, in

Newtons, equal to 20 times the weight of the seat in kilograms

multiplied by 9.8 horizontally through the center of gravity of the

seat back, as shown in Figure 2 and apply forces, in Newtons, equal to

20 times the weight of the seat in kilograms multiplied by 9.8

horizontally through the center of gravity of the seat bench, as shown

in Figure 3.

* * * * *

19. Section 571.212 would be amended by revising S3; revising S5;

revising in S6.1, paragraph (b); and revising S6.5, to read as follows:

Sec. 571.212 Standard No. 212, Windshield mounting.

* * * * *

S3. Application. This standard applies to passenger cars, and to

multipurpose passenger vehicles, trucks, and buses having a gross

vehicle weight rating of 4536 kilograms or less. However, it does not

apply to forward control vehicles, walk-in van-type vehicles, or to

open-body type vehicles with fold-down or removable windshields.

* * * * *

S5. Requirements. When the vehicle travelling longitudinally

forward at any speed up to and including 48 kilometers per hour impacts

a fixed collision barrier that is perpendicular to the line of travel

of the vehicle, under the conditions of S6, the windshield mounting of

the vehicle shall retain not less than the minimum portion of the

windshield periphery specified in S5.1 and S5.2.

S6.1 * * *

(b) Except as specified in S6.2, a multipurpose passenger vehicle,

truck or bus is loaded to its unloaded vehicle weight, plus 136

kilograms or its rated cargo and luggage capacity, whichever is less,

secured to the vehicle, plus a 50th-percentile test dummy as specified

in part 572 of this chapter at each from outboard designated seating

position and at any other position whose protection system is required

to be tested by a dummy under the provisions of Standard No. 208. Each

dummy is restrained only by means that are installed for protection at

its seating position. The load is distributed so that the weight on

each axle as measured at the tire-ground interface is in proportion to

its GAWR. If the weight on any axle when the vehicle is loaded to its

unloaded vehicle weight plus dummy weight exceeds the axle's

proportional share of the test weight, the remaining weight is placed

so that the weight on that axle remains the same. For the purposes of

this section, unloaded vehicle weight does not include the weight of

work-performing accessories. Vehicles are tested to a maximum unloaded

vehicle weight of 2.495 kilograms.

* * * * *

S6.5 The windshield mounting material and all vehicle components in

direct contact with the mounting material are at any temperature

between -93 degrees Celsius and +43 degrees Celsius.

20. Section 571.216 would be amended by revising S3; revising S4;

revising S5; revising in S6.2, paragraph (d); and revising S6.3 to read

as follows:

Sec. 571.216 Standard No. 216, Roof crush resistance--passenger cars.

* * * * *

S3. Application. This standard applies to passenger cars, and to

multipurpose passenger vehicles, trucks and buses with a GVWR of 2722

kilograms or less. However, it does not apply to--

(a) School buses;

(b) Vehicles that conform to the rollover test requirements (S5.3)

of Standard No. 208 (Sec. 571.208) by means that require no action by

vehicle occupants; or

(c) Convertibles, except for optional compliance with the standard

as an alternative to the rollover test requirements in S5.3 of Standard

No. 208.

S4. Requirements--(a) Passenger cars. A test device as described in

S5 shall not move more than 125 millimeters, measured in accordance

with S6.4, when it is used to apply a force in Newtons equal to 1\1/2\

times the unloaded vehicle weight of the vehicle, measured in kilograms

and multiplied by 9.8 or 22,240 Newtons, whichever is less, to either

side of the forward edge of a vehicle's roof in accordance with the

procedures of S6. Both the left and right front portions of the

vehicle's roof structure shall be capable of meeting the requirements,

but a particular vehicle need not meet further requirements after being

tested at one location.

(b) Multipurpose passenger vehicles, trucks and buses with a GVWR

of 2,722 kilograms or less, manufactured on or after September 1, 1994.

For multipurpose passenger vehicles, trucks and buses with a GVWR of

2,722 kilograms or less, manufactured on or after September 1, 1994, a

test device as described in S5 shall not move more than 125

millimeters, measured in accordance with S6.4, when it is used to apply

a force in Newtons equal to 1 \1/2\ times the unloaded vehicle weight

of the vehicle, measured in kilograms and multiplied by 9.8, to either

side of the forward edge of a vehicle's roof in accordance with the

procedures of S6. Both the left and right front portions of the

vehicles's roof structure shall be capable of meeting the requirements,

but a particular vehicle need not meet further requirements after being

tested at one location.

S5. Test device. The test device is a rigid unyielding block with

its lower surface formed as a flat rectangle 762 millimeters x 1829

millimeters.

* * * * *

S6.2 * * *

(d) The initial contact point, or center of the initial contact

area, is on the longitudinal centerline of the lower surface of the

test device and 254 millimeters from the forwardmost point of that

centerline.

6.3 (a) Passenger cars. Apply force in a downward direction

perpendicular to the lower surface of the test device at a rate of not

more than 13 millimeters per second until reaching a force in Newtons

of 1\1/2\ times the unloaded vehicle weight of the tested vehicle,

measured in kilograms and multiplied by 9.8 or 22,240 Newtons,

whichever is less. Complete the test within 120 seconds. Guide the test

device so that throughout the test it moves, without rotation, in a

straight line with its lower surface oriented as specified in S6.2(a)

through S6.2(d).

(b) Multipurpose passenger vehicles, trucks and buses with a GVWR

of 2,722 kilograms or less, manufactured on or after September 1, 1994.

For multipurpose passenger vehicles, trucks and buses with a GVWR of

2,722 kilograms or less, manufactured on or after September 1, 1994,

apply force in a downward direction perpendicular to the lower surface

of the test device at a rate of not more than 13 millimeters per second

until reaching a force in Newtons of 1\1/2\ times the unloaded vehicle

weight of the tested vehicle, measured in kilograms and multiplied by

9.8. Complete the test within 120 seconds. Guide the test device so

that throughout the test it moves, without rotation, in a straight line

with its lower surface oriented as specified in S6.2(a) through

S6.2(d).

* * * * *

21. Section 571.216, would be amended by revising Figure 1 at the

end of the S6.4 to read as follows:

Issued on: March 4, 1994.

Barry Felrice,

Associate Administrator for Rulemaking.

[FR Doc. 94-5486 Filed 3-14-94; 8:45 am]

BILLING CODE 4910-59-M

[Federal Register Volume 59, Number 55 (Tuesday, March 22, 1994)]

[Unknown Section]

[Page 0]

From the Federal Register Online via the Government Printing Office [www.gpo.gov]

[FR Doc No: X94-40322]

[[Page Unknown]]

[Federal Register: March 22, 1994]

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 93-87; Notice 1]

RIN 2127-AF03

Federal Motor Vehicle Safety Standards; Metric Conversion

Correction

In proposed rule document 94-5486 beginning on page 11962, in the

issue of Tuesday, March 15, 1994, make the following corrections:

Sec. 571.120 [Corrected]

1.On page 11967, in the second column, in Sec. 571.120, in

paragraph S5.3.2 Rim, under the heading Truck Example and subheading

SUITABLE TIRE-RIM CHOICE, in the seventh line, ``with 7.50---29-(D)

tires,'' should read ``with 7.50---20-(D) tires,''.

2.On page 11968, in the 1st column, in Sec. 571.120, in paragraph

S5.1.1 Labels., in the 11th line, ``or'' should read ``of''.

3.On the same page, in the same column, in Sec. 571.120 (d), in the

eighth line,`` (------ Ft.)'' should read ``(------ Cubic Ft.)''.

Sec. 571.207 [Corrected]

4.On page 11969, in the third column, in Sec. 571.207 (b), in the

eighth line, ``from'' should read ``front''; and in the second line

from the bottom, ``2.495'' should read ``2,495''.

BILLING CODE 1505-01-D

Issued on: March 4, 1994.

Barry Felrice,

Associate Administrator for Rulemaking.

[FR Doc. 94-5486 Filed 3-14-94; 8:45 am]

BILLING CODE 4910-59-M

[Federal Register Volume 59, Number 55 (Tuesday, March 22, 1994)]

[Unknown Section]

[Page 0]

From the Federal Register Online via the Government Printing Office [www.gpo.gov]

[FR Doc No: X94-40322]

[[Page Unknown]]

[Federal Register: March 22, 1994]

-----------------------------------------------------------------------

DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

49 CFR Part 571

[Docket No. 93-87; Notice 1]

RIN 2127-AF03

Federal Motor Vehicle Safety Standards; Metric Conversion

Correction

In proposed rule document 94-5486 beginning on page 11962, in the

issue of Tuesday, March 15, 1994, make the following corrections:

Sec. 571.120 [Corrected]

1.On page 11967, in the second column, in Sec. 571.120, in

paragraph S5.3.2 Rim, under the heading Truck Example and subheading

SUITABLE TIRE-RIM CHOICE, in the seventh line, ``with 7.50---29-(D)

tires,'' should read ``with 7.50---20-(D) tires,''.

2.On page 11968, in the 1st column, in Sec. 571.120, in paragraph

S5.1.1 Labels., in the 11th line, ``or'' should read ``of''.

3.On the same page, in the same column, in Sec. 571.120 (d), in the

eighth line,`` (------ Ft.)'' should read ``(------ Cubic Ft.)''.

Sec. 571.207 [Corrected]

4.On page 11969, in the third column, in Sec. 571.207 (b), in the

eighth line, ``from'' should read ``front''; and in the second line

from the bottom, ``2.495'' should read ``2,495''.

BILLING CODE 1505-01-D